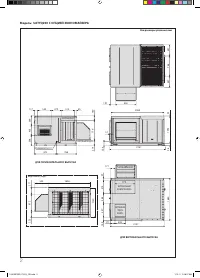

Кондиционеры Daikin UATYQ-CY1 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

39

ENGLISH

G

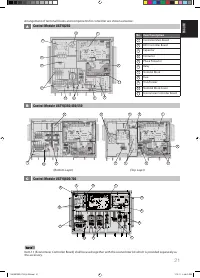

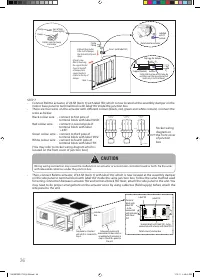

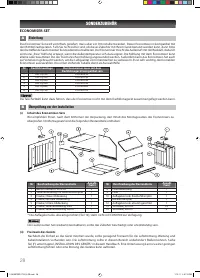

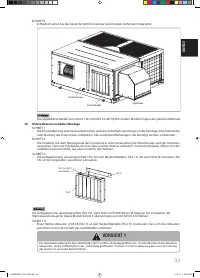

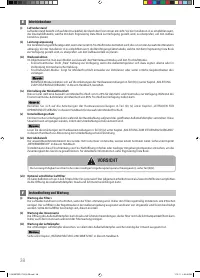

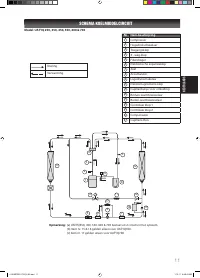

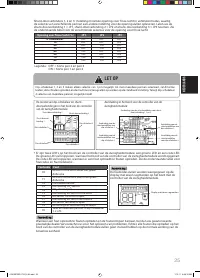

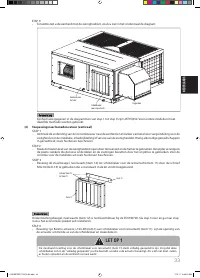

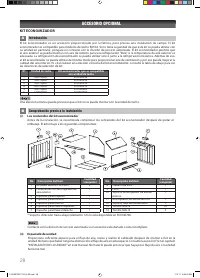

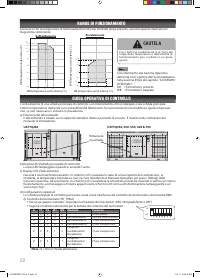

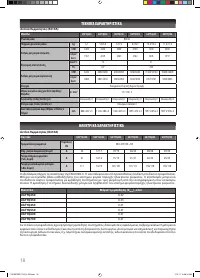

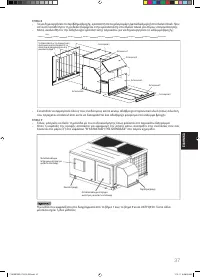

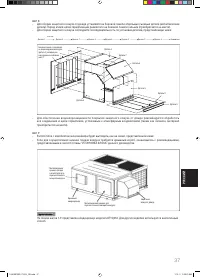

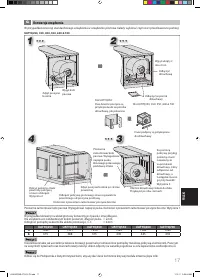

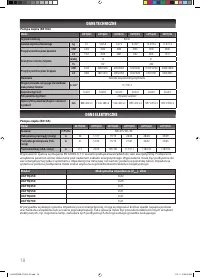

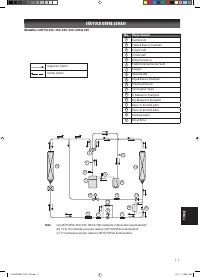

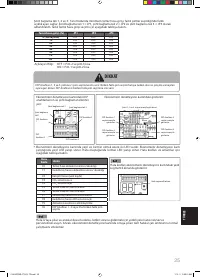

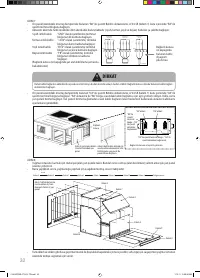

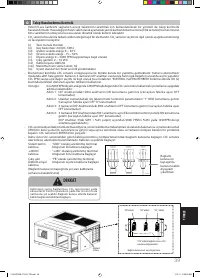

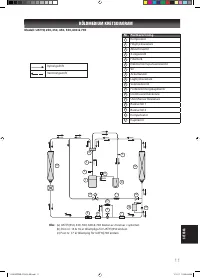

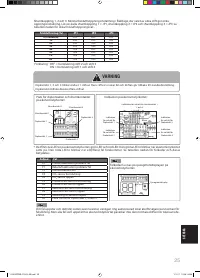

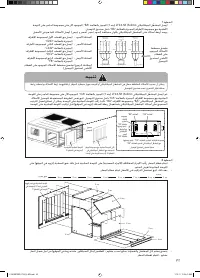

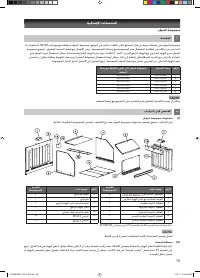

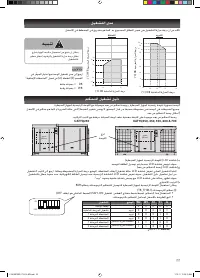

Demand Ventilation Control

- One technique to reduce energy consumption while maintain adequate air quality is demand controlled ventilation.

Instead of setting at a fi xed air replacement rate, carbon dioxide sensor (CO

2

sensor) is used to control the rate

dynamically, based on the emissions of actual building occupants.

- CO

2

sensor is an optional component supplied in fi eld. Refer to the information below for the recommendation of CO

2

sensor selection:

(i)

Type: Duct-mounted type

(ii)

Power input: 24 VDC, 50Hz

(iii) Operating

temperature range: 0 ~ 52°C

(iv)

Ambient temperature range: -15 ~ 52ºC

(v)

Measuring range: 0 ~ 5000 PPM (depends on the application)

(vi)

Output voltage: 2 ~ 10 VDC

(vii) Wire size: AWG18

(viii) Maximum allowable current: 7A

(ix)

Compliance standards: To follow local and national regulations

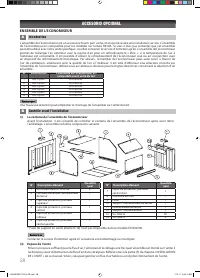

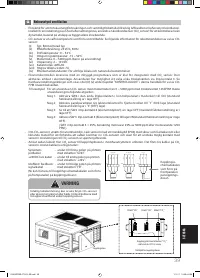

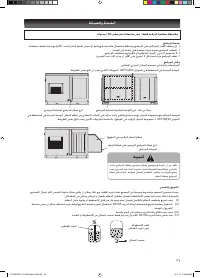

- The economizer controller comes with a build-in software which is ready with the integration of CO

2

sensor. It is activated

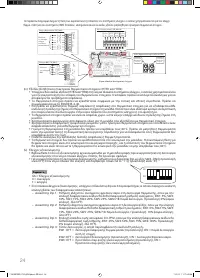

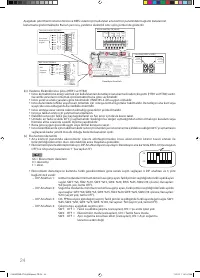

only in economizer mode. User is allowed to choose the diff erent threshold value selection via Dip switch 3. Refer to

hardware setting guideline provided in part (D) (v) under chapter “CONTROL OPERATION GUIDE” in this manual for CO

2

PPM level threshold value selection.

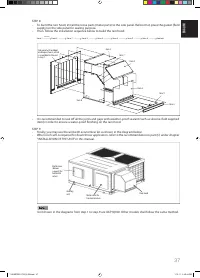

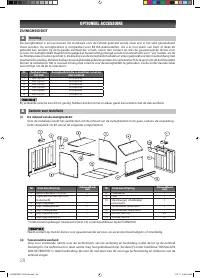

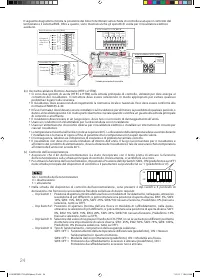

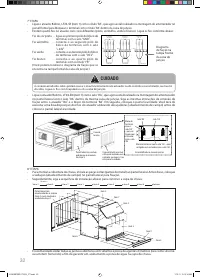

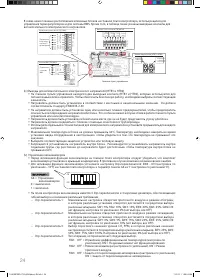

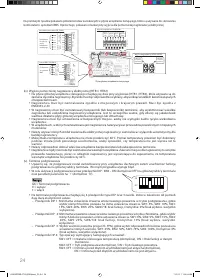

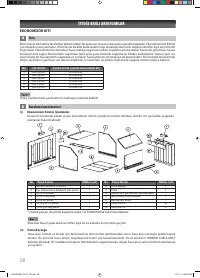

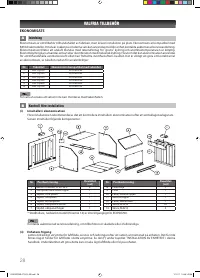

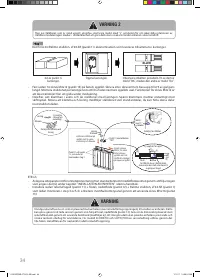

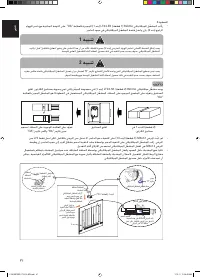

For example: To use a CO

2

sensor with measuring range from 0 ~ 5000 PPM with the threshold value at 1250PPM, user

needs to do the following steps:-

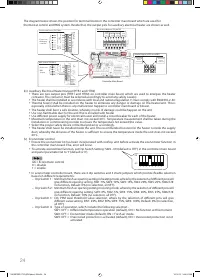

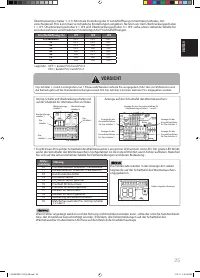

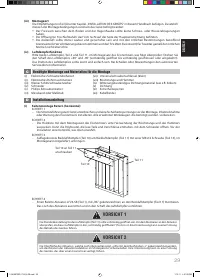

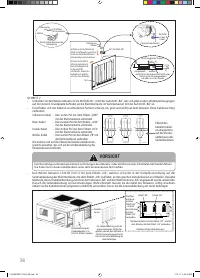

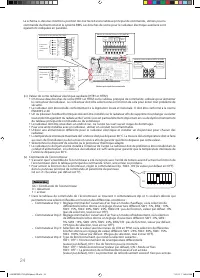

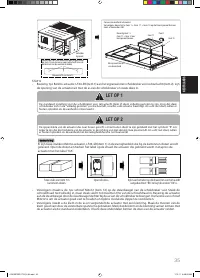

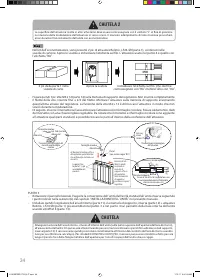

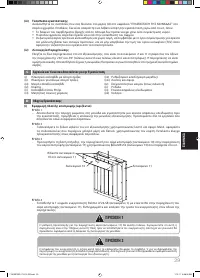

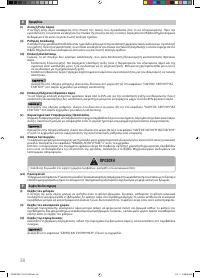

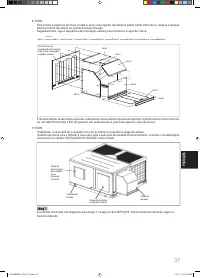

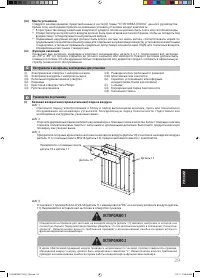

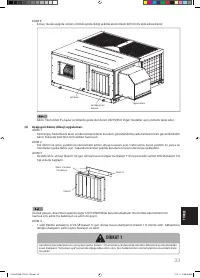

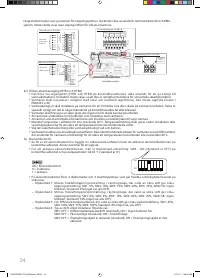

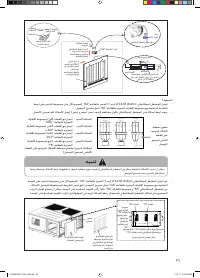

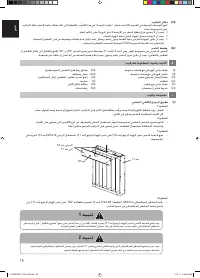

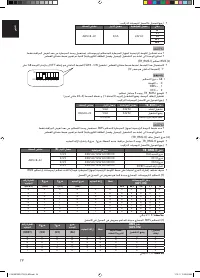

Step 1: Enable SW4 in the only Dip Switch in controller main board to ON position (default factory

setting is in OFF position).

Step 2: Enable panel parameter G6 (economizer control) in remote controller to ‘1’ (ON) position (default

factory setting is in ‘0’ (OFF) position).

Step 3: Ensure SW2 in Dip Switch 4 (Economizer controller board) is in OFF position (default factory

setting is in OFF position).

Step 4: Enable SW1 in Dip Switch 3 (Economizer controller board) to ON position (default factory setting

is in OFF position).

{ SW1 in Dip Switch 3 = 25%, by calculation means 25% of 5000 PPM or equivalent to 1250

PPM }.

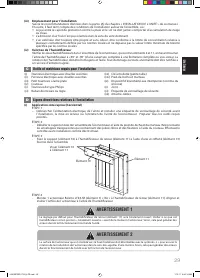

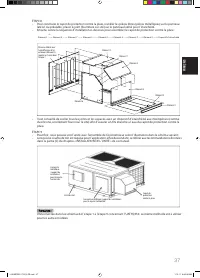

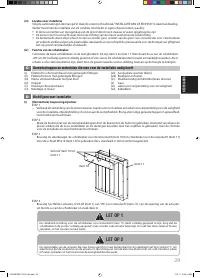

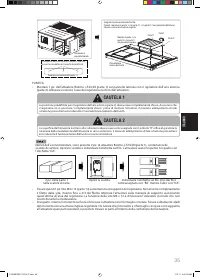

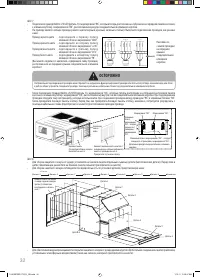

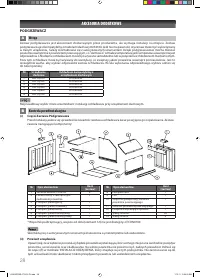

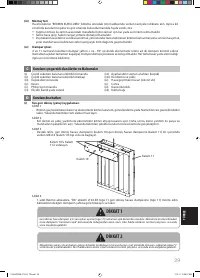

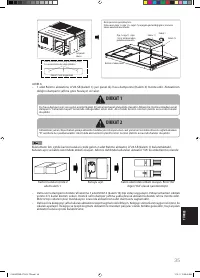

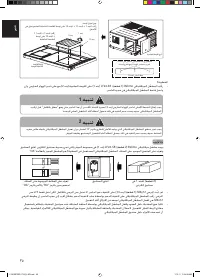

- If the CO

2

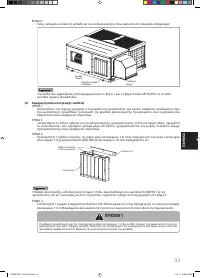

sensor is exposed to outdoor environment, cover the sensor with a splash proof (IPX4) box with screw as

locking mechanism or similar method to prevent water from entering into the CO

2

sensor and also to avoid possible

contact with the sensor. The connection of CO

2

sensor is considered a LIVE part.

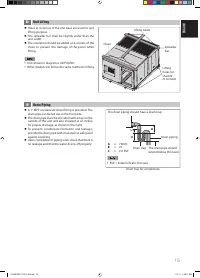

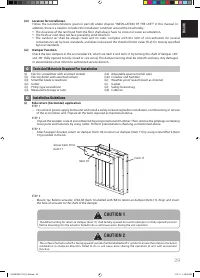

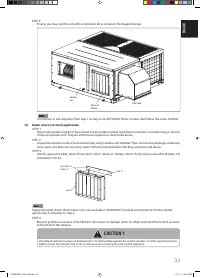

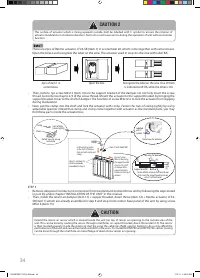

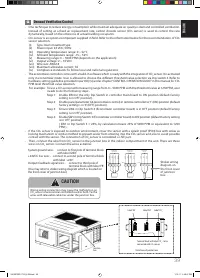

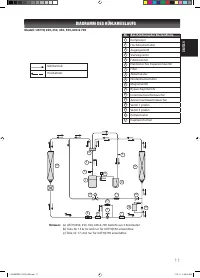

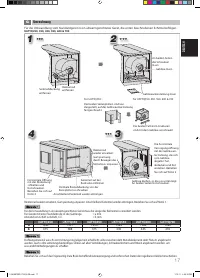

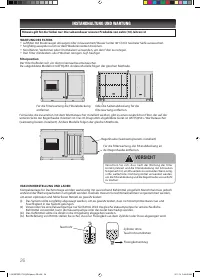

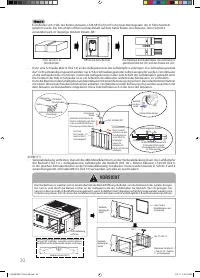

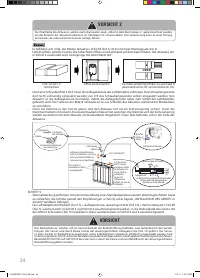

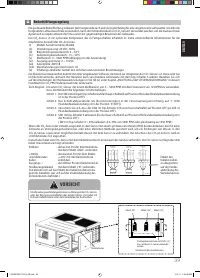

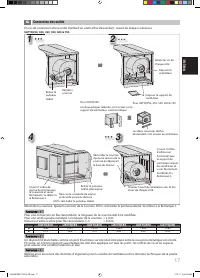

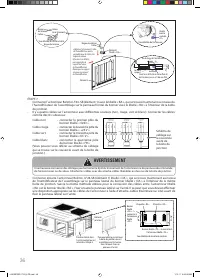

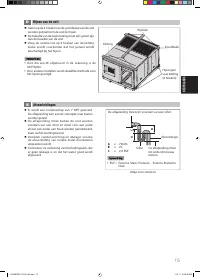

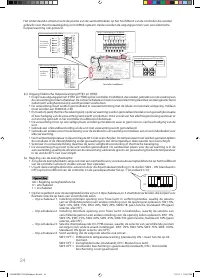

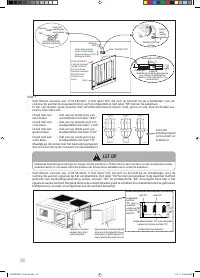

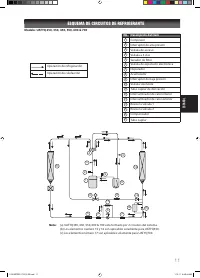

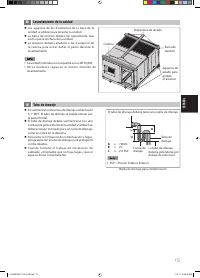

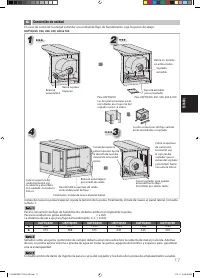

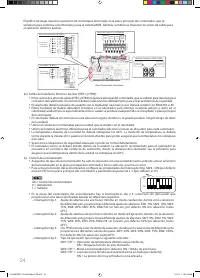

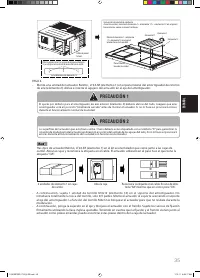

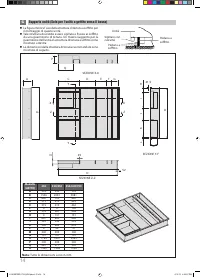

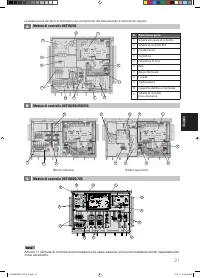

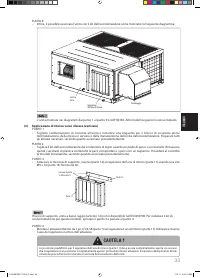

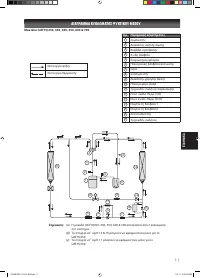

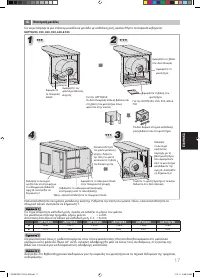

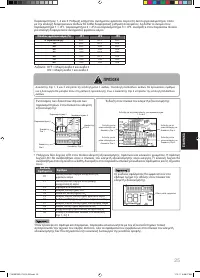

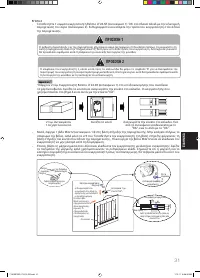

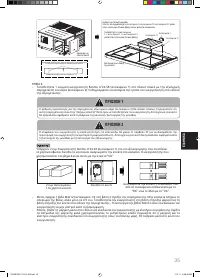

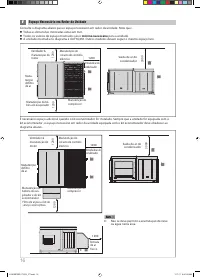

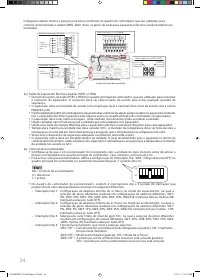

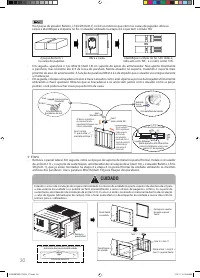

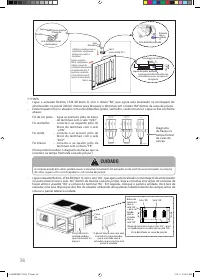

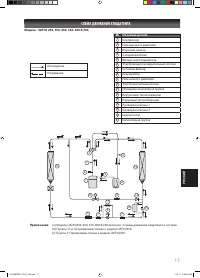

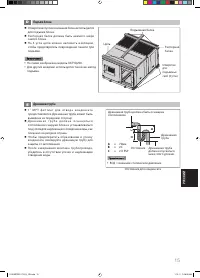

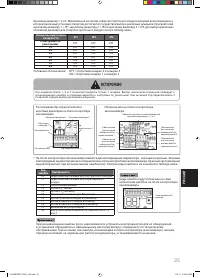

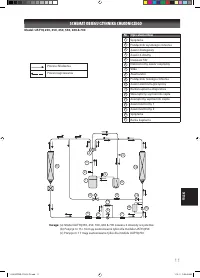

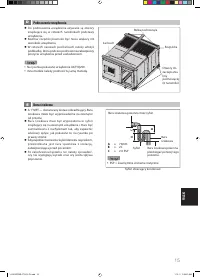

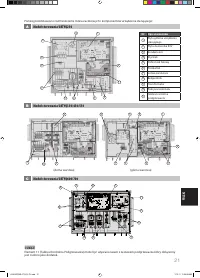

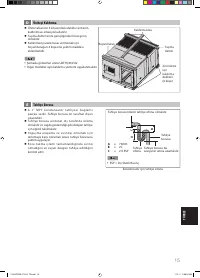

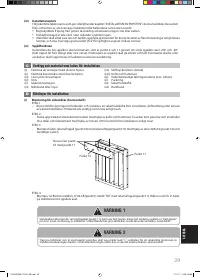

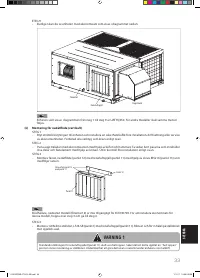

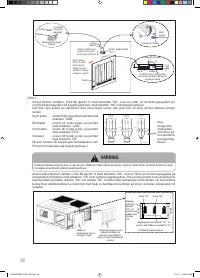

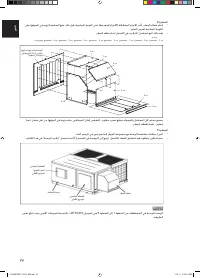

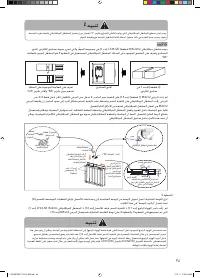

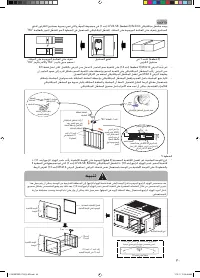

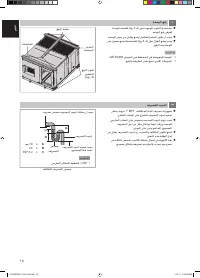

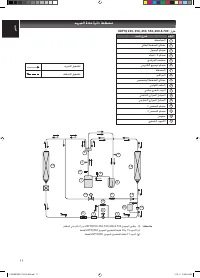

- Then, connect the wire from CO

2

sensor to the junction box in the indoor compartment of the unit. There are three

wires on CO

2

sensor. Connect the wires as below:

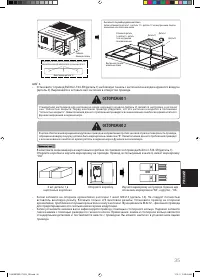

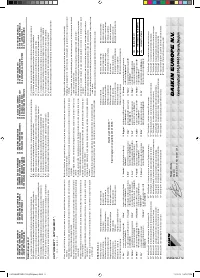

System ground wire - connect to fi rst pole of terminal block

with label ‘GND’.

+24VDC live wire - connect to second pole of terminal block

with label ‘+24V’.

Output/ feedback signal wire - connect to third pole of

terminal block with label ‘FB’.

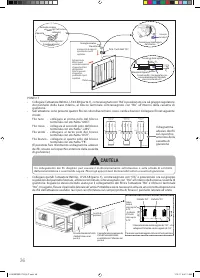

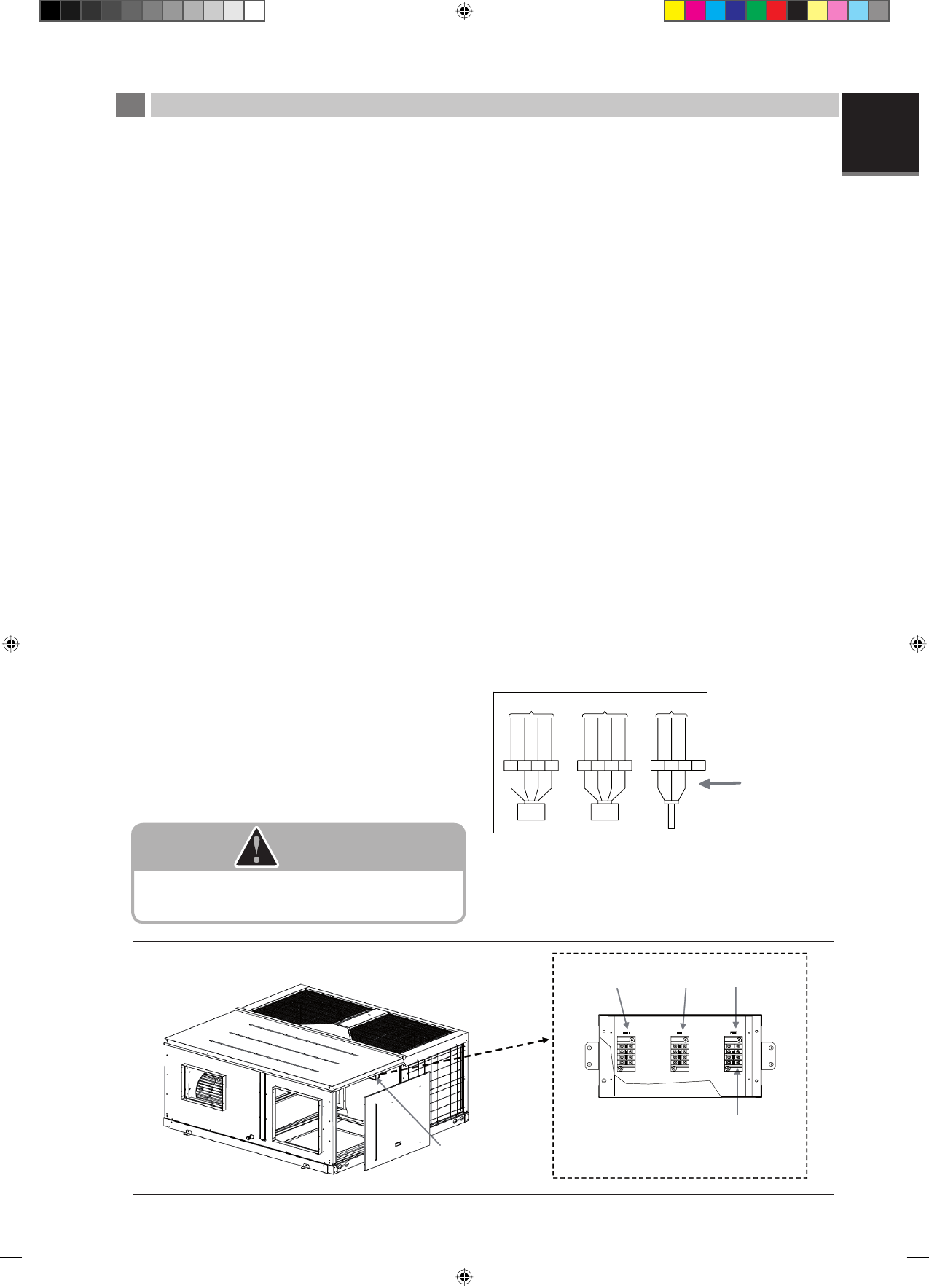

(You may refer to sticker wiring diagram which is located on

the front cover of junction box.)

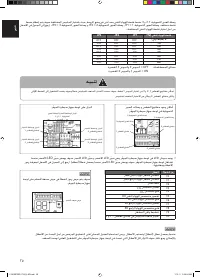

Sticker wiring

diagram on

the front cover

of junction

box

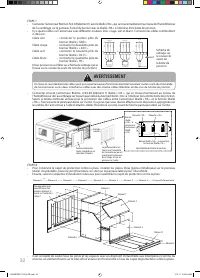

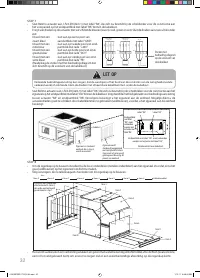

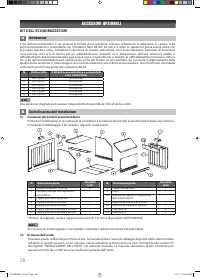

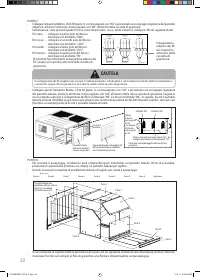

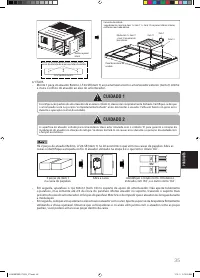

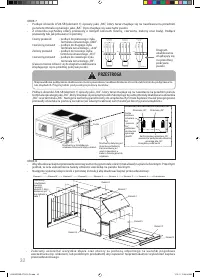

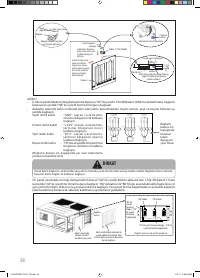

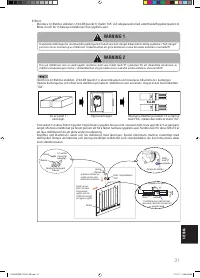

CAUTION

Wrong wiring connection may cause the malfunction on

CO

2

sensor or economizer controller board or both. Tie the

wires with releasable cable ties under the junction box.

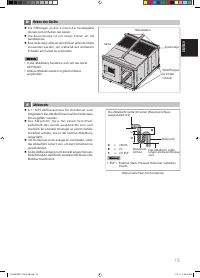

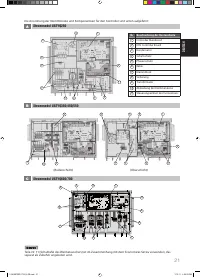

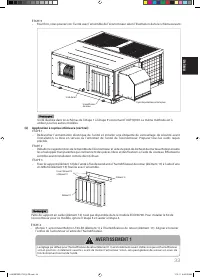

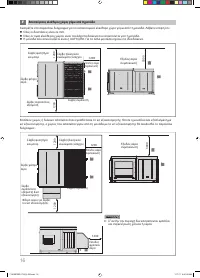

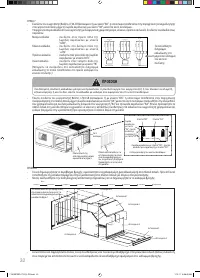

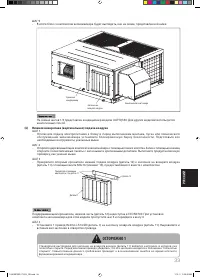

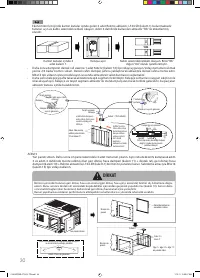

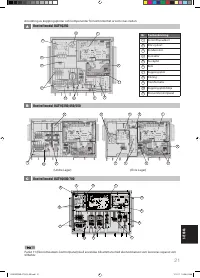

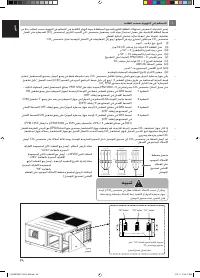

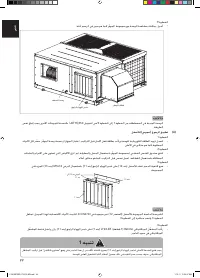

Label ‘RA’

Junction

box

Label ‘OA’

Label ‘CO

2

’

Terminal block with label ‘CO

2

’ - to be

connected with CO

2

sensor.

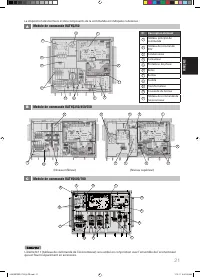

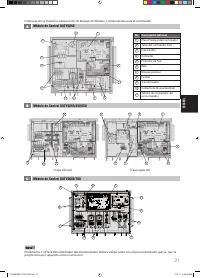

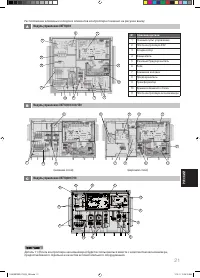

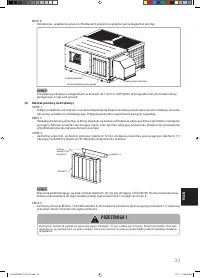

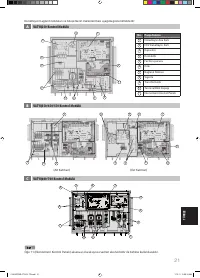

Detail view of junction box

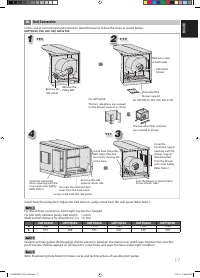

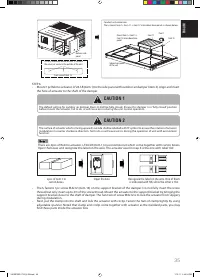

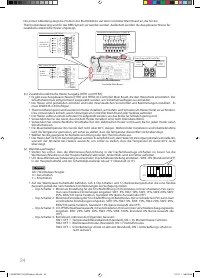

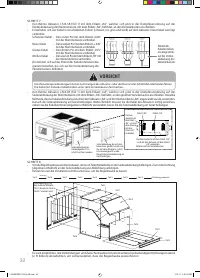

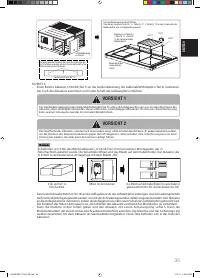

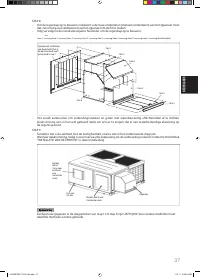

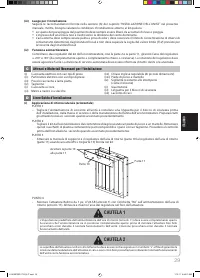

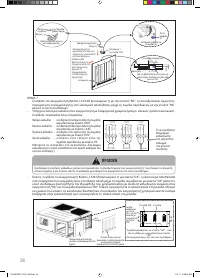

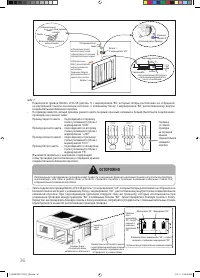

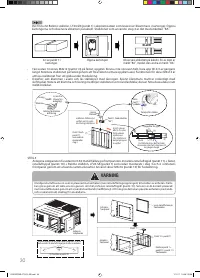

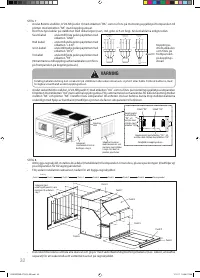

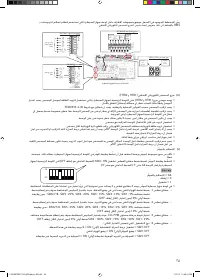

TO PCB3 (ECO)

CN_ACT_RA

TO PCB3 (ECO)

CN_ACT_OA

TO PCB3 (ECO)

CN_C02

TB RA

TB OA

TB C02

BLA

CK

RED

GREEN

WHITE

BLA

CK

RED

GREEN

WHITE

BLA

CK

RED

WHITE

GND +24V DCV

FB

GND +24V DCV

FB

GND +24V

FB

ACTUATOR RA

ACTUATOR OA

C02 SENSOR

1 IM 5RTBR-0710(2)-EN.indd 39

1 IM 5RTBR-0710(2)-EN.indd 39

1/10/11 3:39:37 PM

1/10/11 3:39:37 PM