Электропилы Bosch GCM 12 GDL - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

English |

43

Bosch Power Tools

1 609 92A 0XN | (13.10.14)

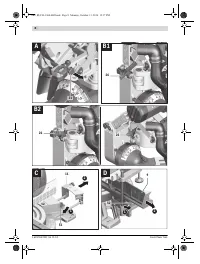

Checking and Adjusting the Basic Adjustment

To ensure precise cuts, the basic adjustment of the machine

must be checked and adjusted as necessary after intensive use.

A certain level of experience and appropriate specialty tools

are required for this.

A Bosch after-sales service station will handle this mainte-

nance task quickly and reliably.

Adjusting the Laser

Note:

To test the laser function, the machine must be con-

nected to power.

While adjusting the laser (e.g. when moving the glide

arm), never actuate the On/Off switch.

Accidental start-

ing of the power tool can lead to injuries.

– Bring the power tool into the working position.

– Turn the saw table

38

to the 0 ° detent

18

. The lever

16

must be felt to engage in the detent.

– Switch on the laser beams with switch

61

.

Checking:

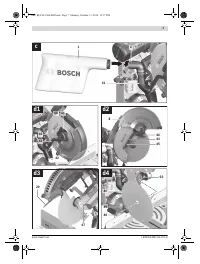

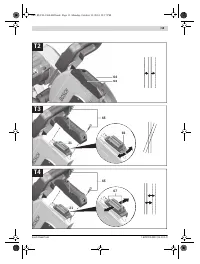

(see figure T1)

– Draw a straight cutting line on the workpiece.

– Press locking lever

5

and slowly guide the glide arm down-

ward with handle

4

.

– Align the workpiece in such a manner that the teeth of the

saw blade are in alignment with the cutting line.

– Hold the workpiece in this position and slowly guide the

glide arm upward.

– Clamp the workpiece.

– Switch on the laser beams with switch

61

.

Throughout the complete length, the laser beams must have

the same clearance to the drawn cutting line on the work-

piece, even when lowering the glide arm.

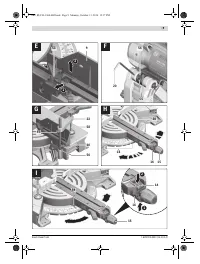

Adjusting the Flush Levelling:

(see figure T2)

– Using the hex key (2 mm)

21

, turn the respective adjust-

ment screw

64

until the laser beam has the same clearance

to the drawn cutting line on the workpiece over the com-

plete length.

One rotation in anticlockwise direction moves the laser beam

from left to right; one rotation in clockwise direction moves

the laser beam from right to left.

Adjusting the Parallelism:

(see figure T3)

– Loosen the two screws

65

of laser protection cap

27

with

the hex key (4 mm)

20

.

Note:

To access the front screw of the laser protection

cap, the glide arm must be tilted down a little until the hex

key can be inserted through one of the slots of the retract-

ing blade guard.

– Loosen fastening screw

66

(approx. 1 – 2 turns) with the

hex key (2 mm)

21

.

Do not completely unscrew the screw.

– Move the mounting plate of the laser right or left until the

laser beams are parallel to the drawn cutting line on the

workpiece over the complete length.

– Hold the mounting plate in this position and tighten fasten-

ing screw

66

again.

– After adjusting, check the flush alignment with the cutting

line once more. If required, align the laser beams with the

set screws

64

one more time.

– Reattach the laser protection cap

27

again.

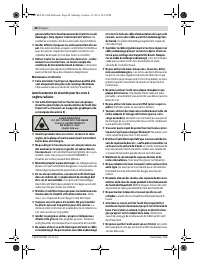

Adjusting the Lateral Deviation when Moving the Glide

Arm:

(see figure T4)

– Loosen the two screws

65

of laser protection cap

27

with

the hex key (4 mm)

20

.

Note:

To access the front screw of the laser protection

cap, the glide arm must be tilted down a little until the hex

key can be inserted through one of the slots of the retract-

ing blade guard.

– Loosen both fastening screws

67

(approx. 1 – 2 turns)

with the hex key (2 mm)

21

.

Do not completely unscrew the screws.

– Move the laser housing right or left until the laser beams no

longer deviate in lateral direction when moving the glide

arm down.

– After adjusting, check the flush alignment with the cutting

line once more. If required, align the laser beams with the

set screws

64

one more time.

– Hold the laser housing in this position and tighten fasten-

ing screws

67

again.

– Reattach the laser protection cap

27

again.

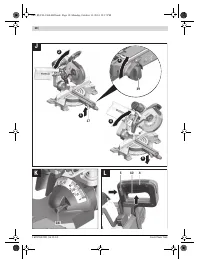

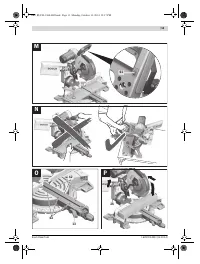

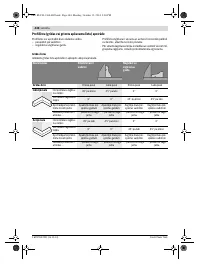

Setting the Standard Bevel Angle 0 ° (Vertical)

– Bring the machine into the transport position.

– Turn the saw table

38

to the 0 ° detent

18

. The lever

16

must be felt to engage in the detent.

Checking:

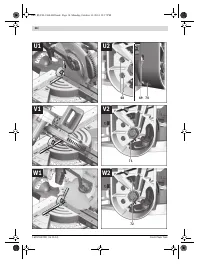

(see figure U1)

– Set an angle gauge to 90 ° and place it on the saw table

38

.

The leg of the angle gauge must be flush with the saw blade

40

over the complete length.

Adjusting:

(see figure U2)

– Loosen the lock lever

17

.

– Loosen both set screws

68

(by at least 1 turn) using a sock-

et spanner (size 10 mm).

– Loosen set screw

70

(approx. 3 turns) with the hex key

(4 mm)

20

.

– Screw set screw

69

with the hex key (4 mm)

20

in or out

until the leg of the angle gauge is flush with the saw blade

over the complete length.

– Retighten the lock lever

17

again.

Afterwards, tighten set screw

70

first, and then set screws

68

.

When the angle indicators

33

and

24

are not in line with the

0 ° marks of scale

32

after adjusting, loosen the fastening

screws of the angle indicators with a cross-head screwdriver

and align the angle indicators alongside the 0 ° marks.

OBJ_BUCH-1360-002.book Page 43 Monday, October 13, 2014 12:18 PM

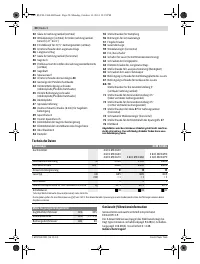

Содержание

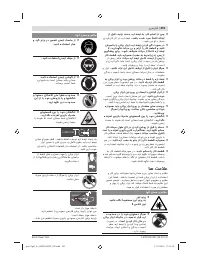

- 277 Защищайте электроинструмент от дождя и сырости.

- 278 Держите Ваше рабочее место в чистоте.

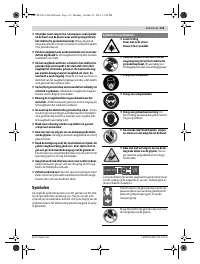

- 279 Закрепляйте заготовку.; Символы; Символы и их значение

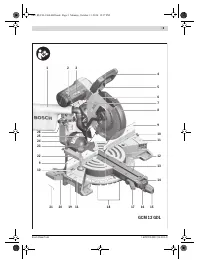

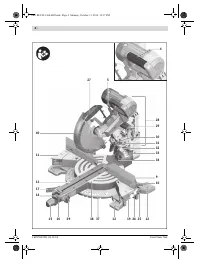

- 280 Описание продукта и услуг; Применение по назначению

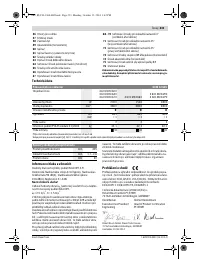

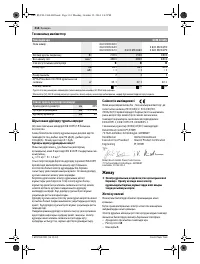

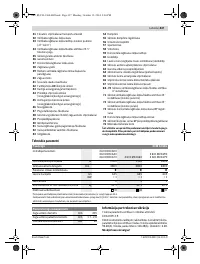

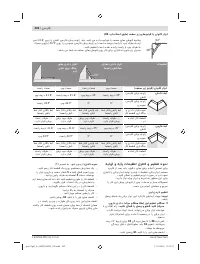

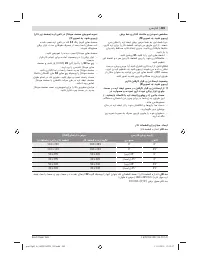

- 281 Технические данные; Применяйте средства защиты органов слуха!; Размеры пильных дисков

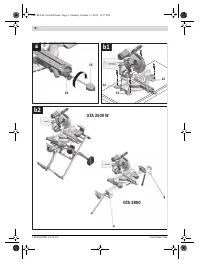

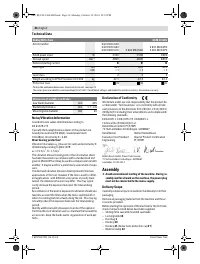

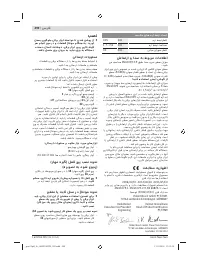

- 282 Заявление о соответствии; Сборка; Комплект поставки

- 283 Избегайте скопления пыли на рабочем месте.

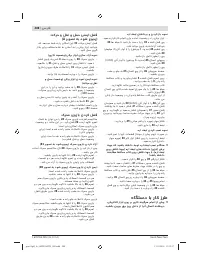

- 284 Работа с инструментом; Фиксация кронштейна; мягкого; более жесткого

- 285 Настройка горизонтального угла распила; Стандартный угол распила 0 °

- 286 Включение электроинструмента

- 287 Минимальные; Пиление; Специальные заготовки

- 288 Плинтусы

- 289 Основные настройки – контроль и коррекция; Настройка ровности

- 291 Техобслуживание и сервис; Техобслуживание и очистка; Очистка; Принадлежности; Пильные диски для пластмассы и цветных металлов

- 292 Россия; Утилизация