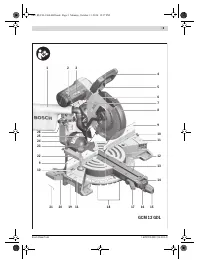

Электропилы Bosch GCM 12 GDL - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

38

| English

1 609 92A 0XN | (13.10.14)

Bosch Power Tools

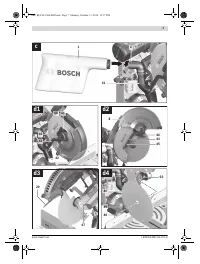

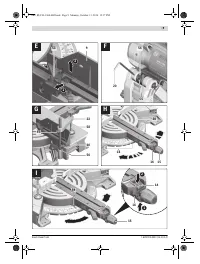

Removing the Saw Blade

– Bring the power tool into the working position.

– Unscrew locking screw

42

by hand until the linkage

43

can

hang freely.

– Loosen fastening screw

44

(approx. 2 turns) with the hex

key (4 mm)

20

.

Do not completely unscrew the screw.

– Loosen the fastening screw

45

(approx. 6 turns) with the

hex key (4 mm)

20

.

Do not completely unscrew the screw.

– Pull cover plate

46

off of fastening screw

45

toward the

front and bottom.

– Press locking lever

5

and swing back the retracting blade

guard

8

.

Hold the retracting blade guard in this position.

– Hang linkage

43

over fastening screw

45

via a bolt hole.

This holds the retracting blade guard in the open position.

– Turn the hex socket screw

48

with the hex key (6 mm)

20

and at the same time press the spindle lock

47

until it en-

gages.

– Hold the spindle lock

47

pressed and unscrew the hex

socket screw

48

in clockwise direction (left-hand thread!).

– Remove the clamping flange

49

.

– Remove the saw blade

40

.

Mounting the Saw Blade

If required, clean all parts to be mounted prior to assembly.

– Place the new saw blade onto the interior clamping flange

50

.

When mounting the saw blade, pay attention that the

cutting direction of the teeth (arrow direction on the

saw blade) corresponds with the direction of the arrow

on the blade guard!

– Place on the clamping flange

49

and the screw

48

.

Press the spindle lock

47

until it engages and tighten the

screw turning in anticlockwise direction.

– Release linkage

43

from fastening screw

45

and guide the

retracting blade guard down again.

– Slide cover plate

46

under fastening screw

45

again.

– Retighten the fastening screws

45

and

44

again.

– Slide linkage

43

onto its original position and retighten

locking screw

42

by hand again.

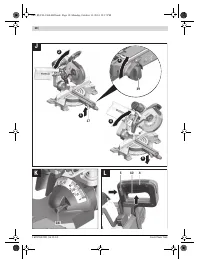

Operation

Before any work on the machine itself, pull the mains

plug.

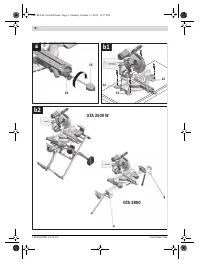

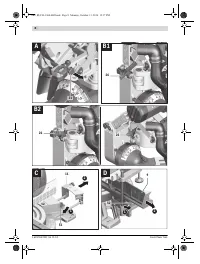

Transport Safety (see figure A)

The transport safety-lock

31

enables easier handling of the

machine when transporting to various working locations.

Releasing the Machine (Working Position)

– Slightly push down glide arm

28

by handle

4

to release

transport safety-lock

31

.

– Pull the transport safety-lock

31

completely outward.

– Slowly guide the glide arm upward.

Securing the Machine (Transport Position)

– Slide glide arm

28

completely to the rear and secure it in

this position (see “Securing the Glide Arm”, page 38).

– Guide the glide arm downward until transport safety-lock

31

can be pushed completely inward.

For additional information on transport, see page 44.

Locking the Glide Arm

The glide mechanism of glide arm

28

can be locked with lock

lever

26

. Two glide arm positions are possible:

– Glide arm pushed completely to the rear (for chop-cuts)

– Glide arm pulled completely to the front (for a compact

transport position)

Releasing the Glide Arm (see figure B1)

After releasing the glide arm

28

, the complete pulling mecha-

nism is ready for operation.

– Push the lock lever

26

down to the stop.

The clamping wedge of the lock lever releases both bottom

joint parts of the glide arm.

Securing the Glide Arm (see figure B2)

Glide arm pushed completely to the rear:

– Push glide arm

28

toward the rear to the stop.

The two upper joint parts of the glide arm are now in the up-

right position and shut.

– Pull lock lever

26

upward until of the clamping wedge is po-

sitioned between the two bottom joint parts of the glide

arm.

This locks the completely pushed back glide arm

28

.

Glide arm pulled completely to the front:

– Pull glide arm

28

forward to the stop.

The glide mechanism is now completely extended.

– Pull lock lever

26

upward until of the clamping wedge is po-

sitioned between the two bottom joint parts of the glide

arm.

This locks the completely forward pulled glide arm

28

.

Preparing for Operation

Extending the Saw Table (see figure C)

Long workpieces must be underlaid or supported at their free

end.

The saw table can be extended left and right with the saw-ta-

ble extensions

11

.

– Push clamping lever

51

inward.

– Pull out saw-table extension

11

to the desired length (max.

250 mm).

– To lock the saw-table extension, push clamping lever

51

outward again.

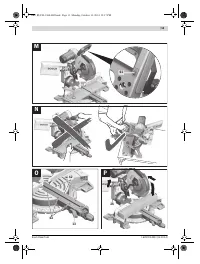

Extending the Fence (see figure D)

For bevel angles, the fence extensions

9

must be moved.

– Turn clamping lever

52

toward the front.

– Pull the fence extension

9

completely outward.

– To lock the adjustable fence, push clamping lever

52

down

again.

OBJ_BUCH-1360-002.book Page 38 Monday, October 13, 2014 12:18 PM

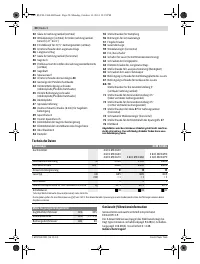

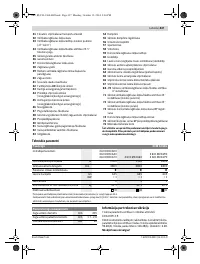

Содержание

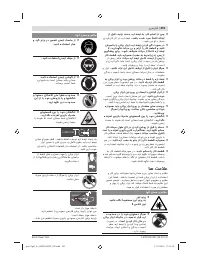

- 277 Защищайте электроинструмент от дождя и сырости.

- 278 Держите Ваше рабочее место в чистоте.

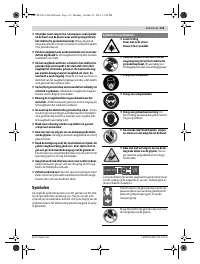

- 279 Закрепляйте заготовку.; Символы; Символы и их значение

- 280 Описание продукта и услуг; Применение по назначению

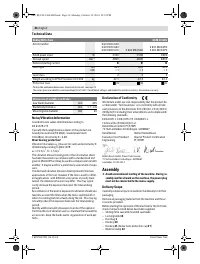

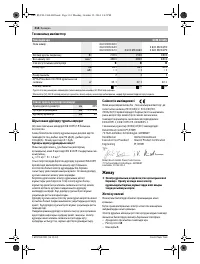

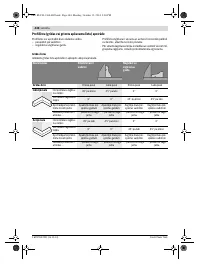

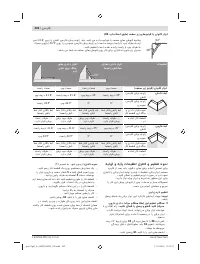

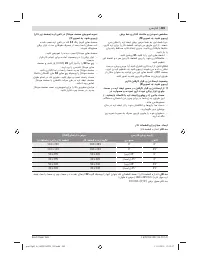

- 281 Технические данные; Применяйте средства защиты органов слуха!; Размеры пильных дисков

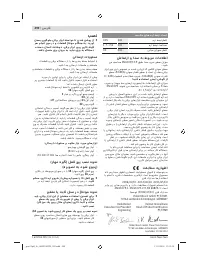

- 282 Заявление о соответствии; Сборка; Комплект поставки

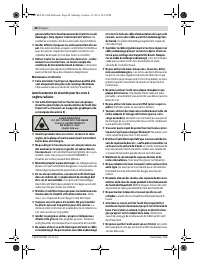

- 283 Избегайте скопления пыли на рабочем месте.

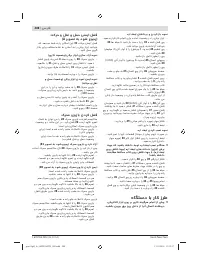

- 284 Работа с инструментом; Фиксация кронштейна; мягкого; более жесткого

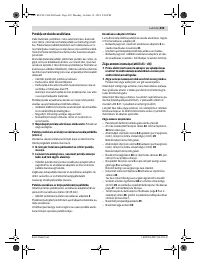

- 285 Настройка горизонтального угла распила; Стандартный угол распила 0 °

- 286 Включение электроинструмента

- 287 Минимальные; Пиление; Специальные заготовки

- 288 Плинтусы

- 289 Основные настройки – контроль и коррекция; Настройка ровности

- 291 Техобслуживание и сервис; Техобслуживание и очистка; Очистка; Принадлежности; Пильные диски для пластмассы и цветных металлов

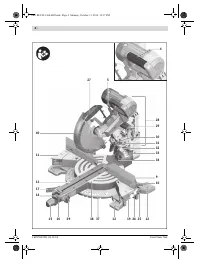

- 292 Россия; Утилизация