Котел De Dietrich MS 24 BIC FF - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

66

71.06199.02 - EN

INSTALLATION INSTRUCTIONS

This boiler has been designed to heat water to a temperature lower than boiling point at atmospheric pressure.

It must be connected to a central heating system and to a domestic hot water supply system according to its performance

and power output.

Do the following before connecting the boiler:

a) Make sure that the boiler is adjusted to use the type of gas delivered by the gas supply. To do this, check the markings

on the packaging and the rating plate on the appliance.

b) Make sure that the lue terminal draft is appropriate, that the terminal is not obstructed and that no exhaust gases

from other appliances are expelled through the same lue duct, unless the latter has been specially designed to collect

exhaust gas from more than one appliance, in compliance with current laws and regulations.

c) Make sure that, if the boiler is connected to existing lue ducts, these have been thoroughly cleaned as residual products

of combustion may detach from the walls during operation and obstruct the low of fumes.

To ensure correct operation and maintain the warranty, observe the following precautions:

1. DHW circuit:

1.1.

If the water is harder than 20 °F (1 °F = 10 mg calcium carbonate per litre of water), install a polyphosphate dispenser

or an equivalent treatment system, compliant with current regulations.

1.2.

Thoroughly lush the system after installation of the appliance and before use.

1.3.

The materials used for the product’s DHW circuit comply with Directive 98/83/CE.

2. Heating circuit

2.1. new system

Before proceeding with installation of the boiler, the system must be cleaned and lushed to eliminate residual

thread-cutting swarf, solder and any solvents, using suitable proprietary products. To avoid damaging metal, plastic

and rubber parts, only use neutral cleaners, i.e. non-acid and non alkaline. Recommended cleaning products are:

SENTINEL X300 or X400 and FERNOX Regenerator for heating circuits. Use these products in strict compliance

with the manufacturers’ instructions.

2.2. existing system:

Before installing the boiler, drain the system and clean it to remove sludge and contaminants, using suitable

proprietary products as described in section 2.1.

To avoid damaging metal, plastic and rubber parts, use only neutral cleaners, i.e. non-acid and non-alkaline such

as SENTINEL X100 and FERNOX Protector for heating circuits. Use these products in strict compliance with the

manufacturers’ instructions.

Remember that the presence of foreign bodies in the heating system can adversely affect boiler operation (e.g.

overheating and excessive noise of the heat exchanger).

Failure to observe the above will render the warranty null and void

.

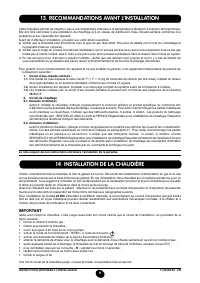

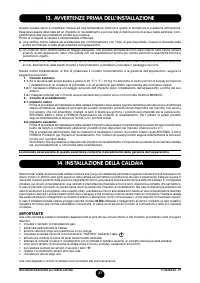

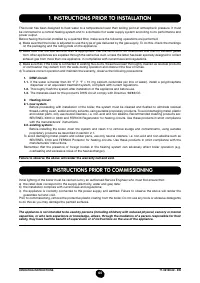

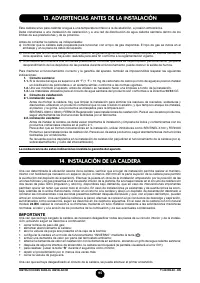

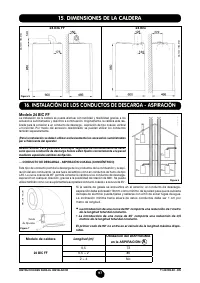

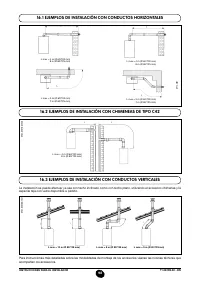

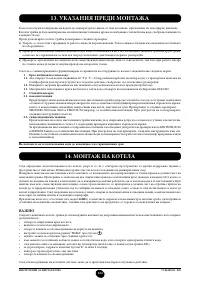

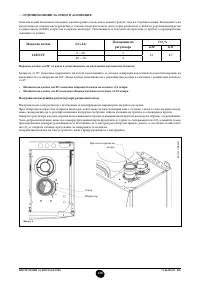

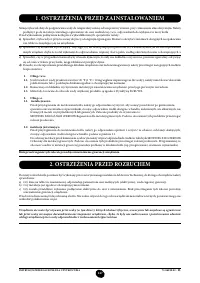

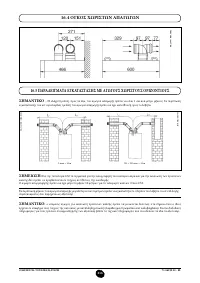

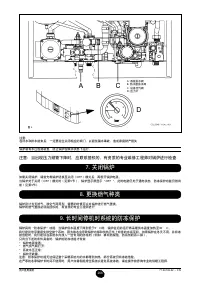

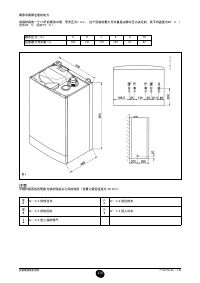

13. INSTRUCTIONS PRIOR TO INSTALLATION

13. INSTALLAZIONE DELLA CALDAIA

14. INSTALLING THE BOILER

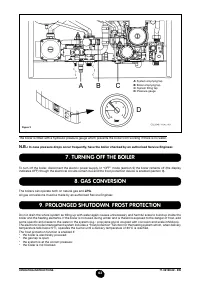

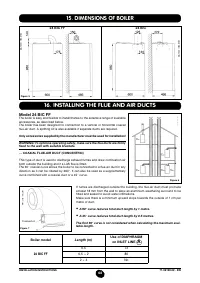

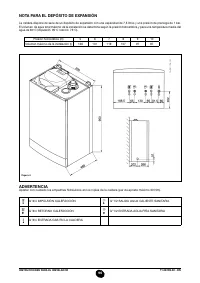

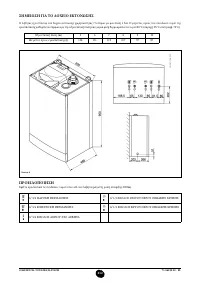

After deciding the exact location of the boiler, make sure there is suficient room to perform maintenance operations (at

least 450 mm of headroom is required in order to replace the expansion vessel).

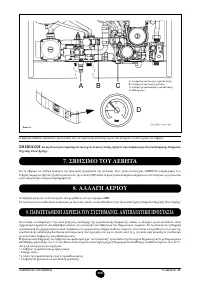

Connect the system to the gas and water inlets present on the lower bar of the template. Fit two G3/4 taps (low and

return) on the central heating circuit; these taps make it possible to carry out important operations on the system without

draining it completely. If you are either installing the boiler on an existing system or replacing one, as well as the above,

it a settling tank under the boiler on the system return line in order to collect any deposits and scale circulating in the

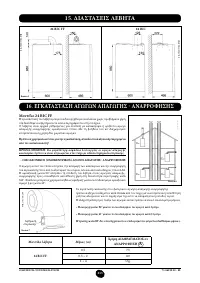

system after lushing. After ixing the boiler to the template, connect the lue and air ducts, supplied as accessories, as

described in the following sections.

If the model

24 BIC

natural draught boiler is installed, connected it to the lue with a metal pipe resistant to normal me-

chanical stress, heat, products of combustion and relative condensate.

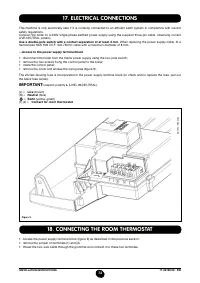

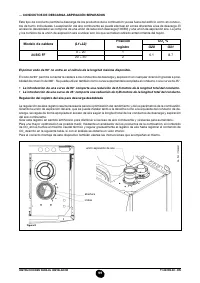

IMPORTANT

After illing the boiler, vent the entire internal circuit and the system as follows:

• close the gas on-off valve;

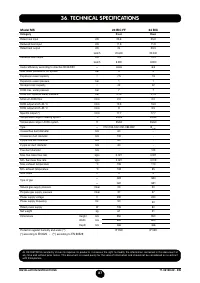

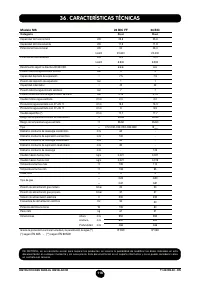

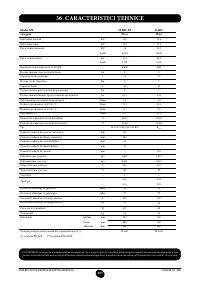

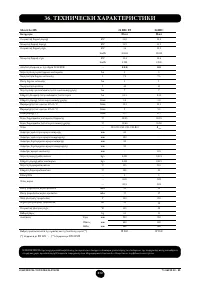

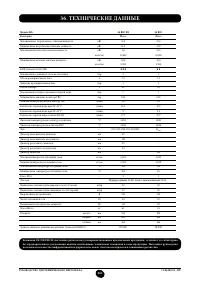

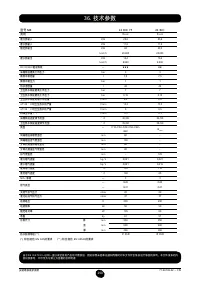

• power the boiler.

• open the vent valve on the pump body;

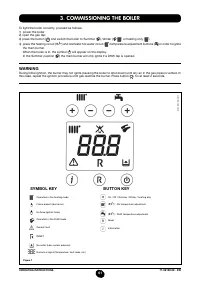

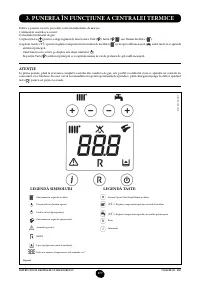

• press (

) to set the boiler in the “WINTER” operating mode;

• send a heat demand from the room thermostat;

• open a hot water tap to alternate CH demand with DHW demand;

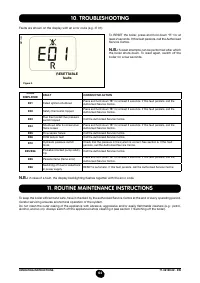

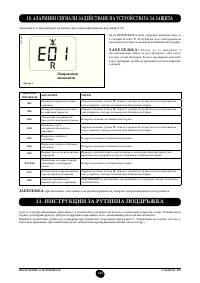

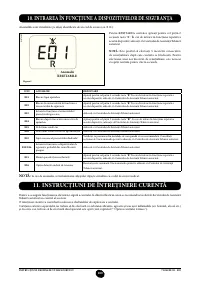

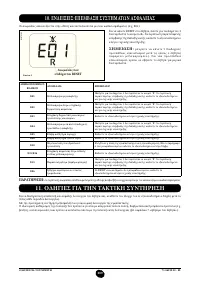

• after a few ignition attempts the boiler will shut down (error E01 appears on the display);

• to rest, press and hold down “

R

” for at least 2 seconds;

• repeat the procedure at least another two times;

• close the vent valve.

After venting the boiler circuit, proceed with initial lighting.

Содержание

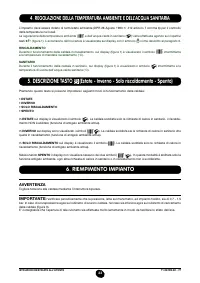

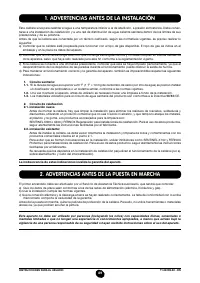

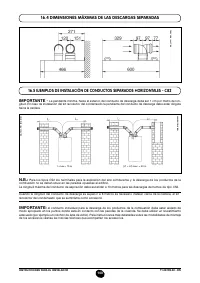

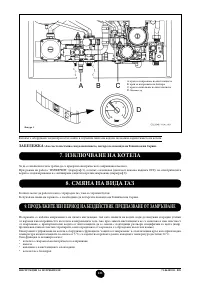

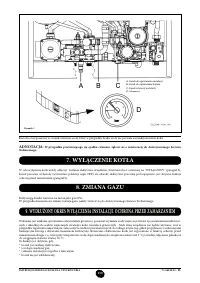

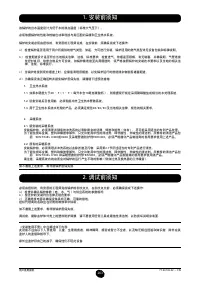

- 234 ПОДГОТОВКА К УСТАНОВКЕ; ПОДГОТОВКА К ПЕРВОМУ ПУСКУ

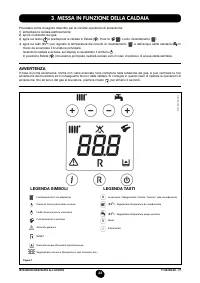

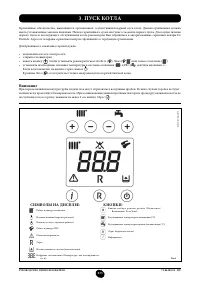

- 235 Внимание

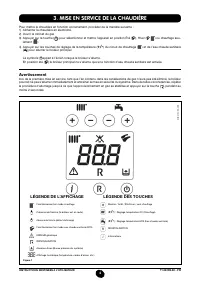

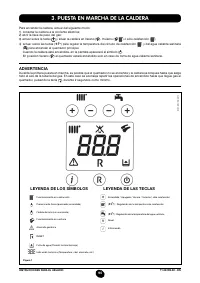

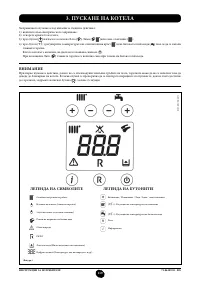

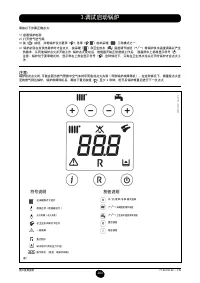

- 236 ОПИСАНИЕ КНОПКИ (Лето – Зима – Только Отопление – Выключено); ЗАПОЛНЕНИЕ СИСТЕМЫ

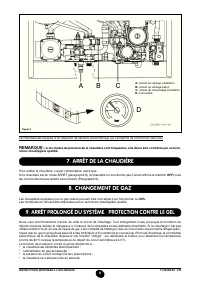

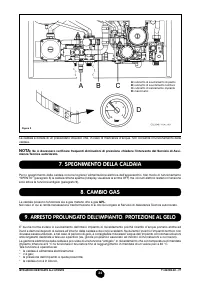

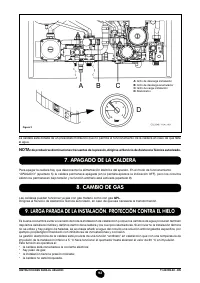

- 237 ВЫКЛЮЧЕНИЕ КОТЛА; ВЫКЛЮЧЕНИЕ НА ДЛИТЕЛЬНЫЙ ПЕРИОД. ЗАЩИТА ОТ ЗАМЕРЗАНИЯ

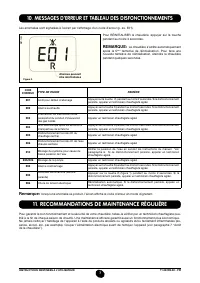

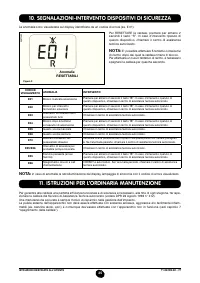

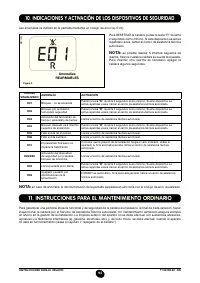

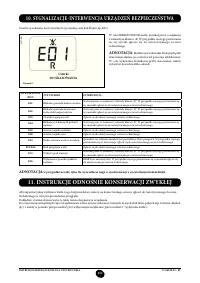

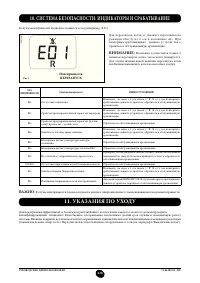

- 238 СИСТЕМА БЕЗОПАСНОСТИ: ИНДИКАТОРЫ И СРАБАТЫВАНИЕ; Неисправность

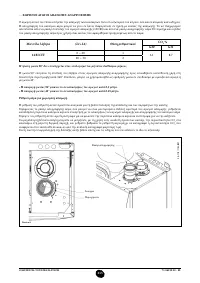

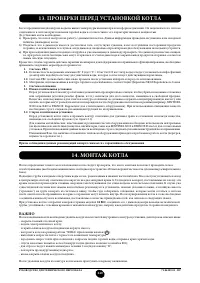

- 240 ПРОВЕРКИ ПЕРЕД УСТАНОВКОЙ КОТЛА

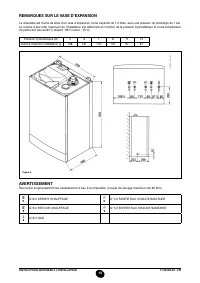

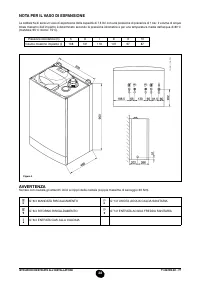

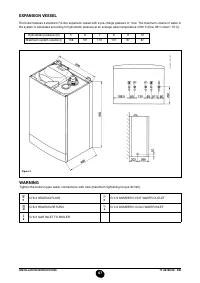

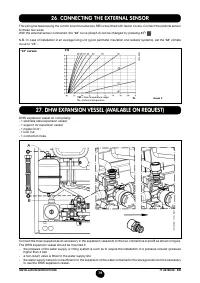

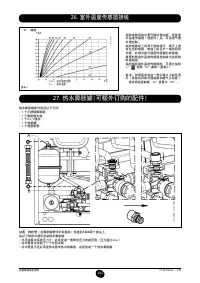

- 241 ПРИМЕЧАНИЕ ПО РАСШИРИТЕЛЬНОМУ БАКУ

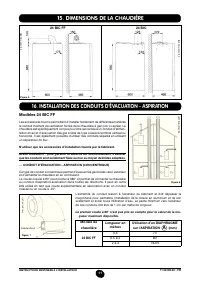

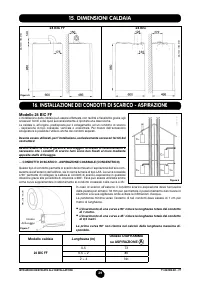

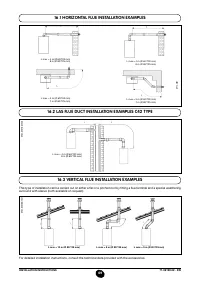

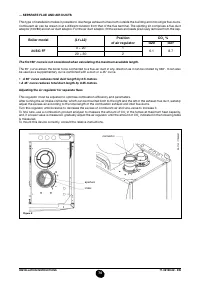

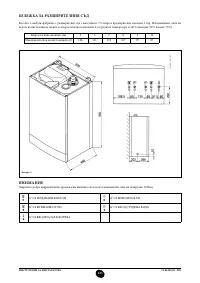

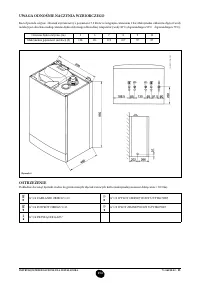

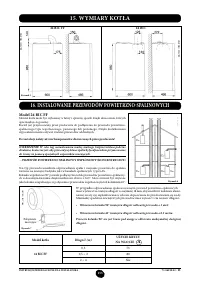

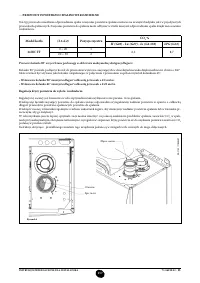

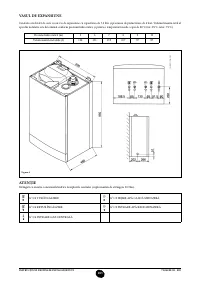

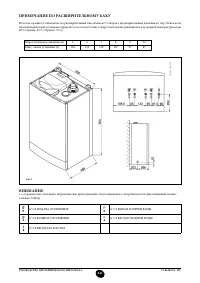

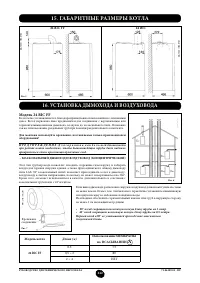

- 242 Модель 24 BIC FF; Модель котла; НЕТ

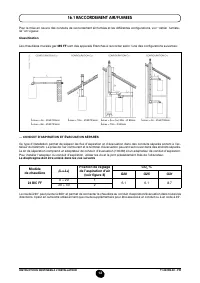

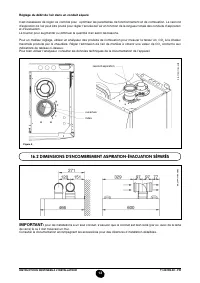

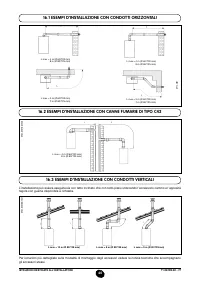

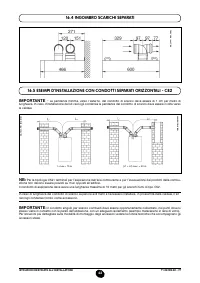

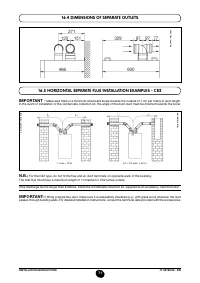

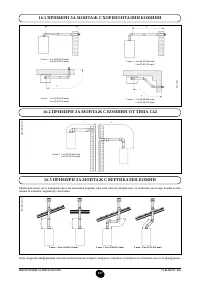

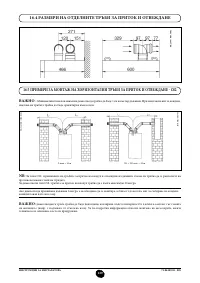

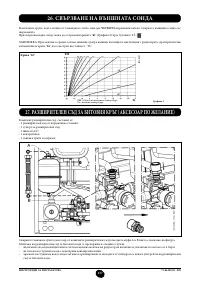

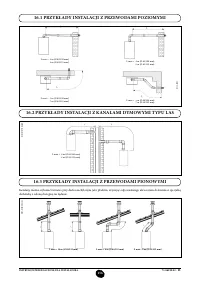

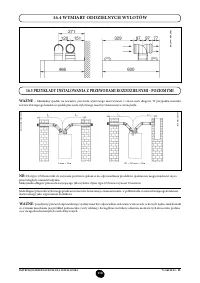

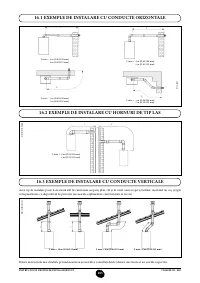

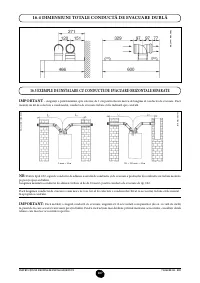

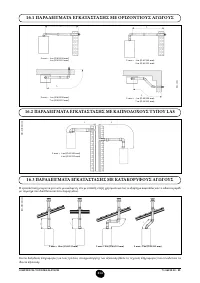

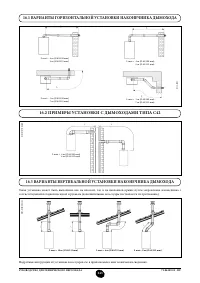

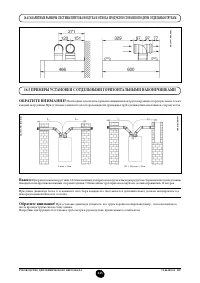

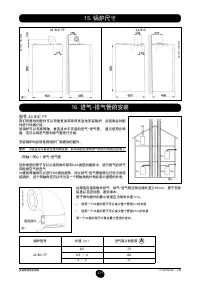

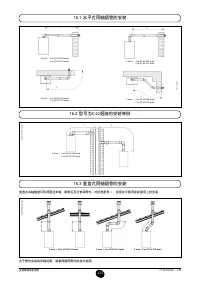

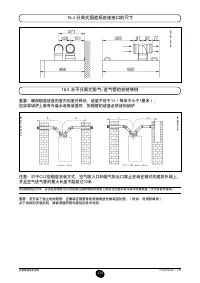

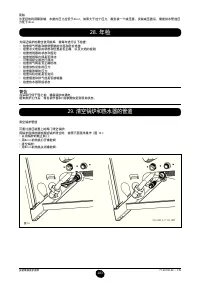

- 243 ВАРИАНТЫ ГОРИЗОНТАЛЬНОЙ УСТАНОВКИ НАКОНЕЧНИКА ДЫМОХОДА

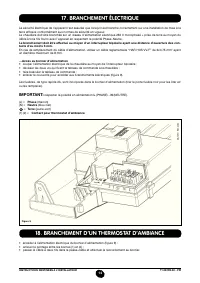

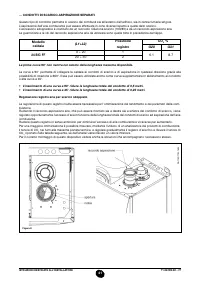

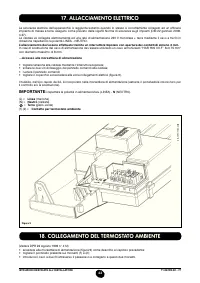

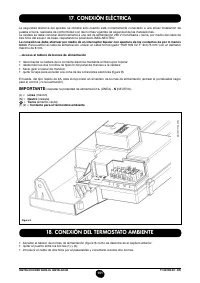

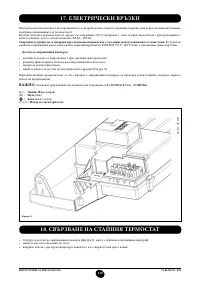

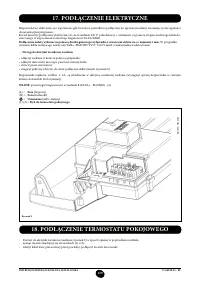

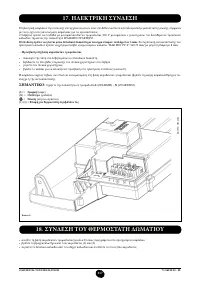

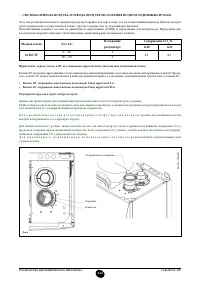

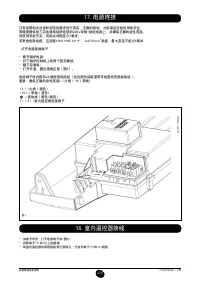

- 246 ПОДКЛЮЧЕНИЕ К ЭЛЕКТРОПИТАНИЮ; ПОДСОЕДИНЕНИЕ КОМНАТНОГО ТЕРМОСТАТА

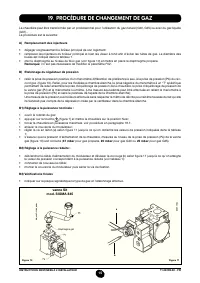

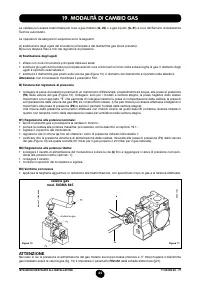

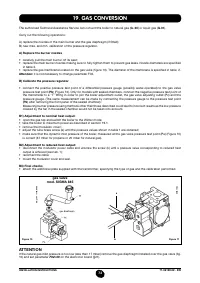

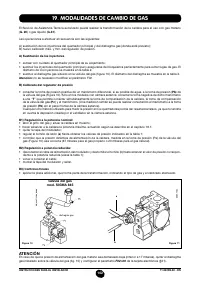

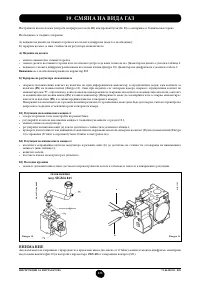

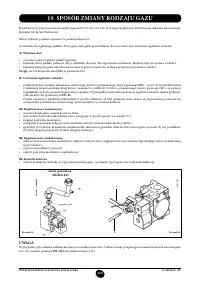

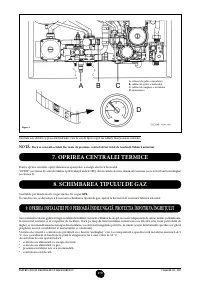

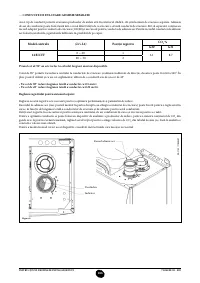

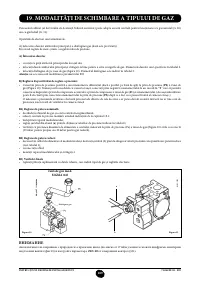

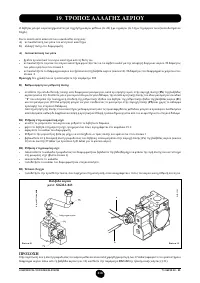

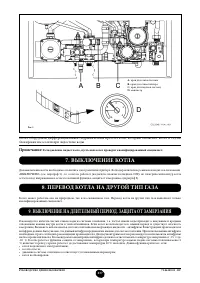

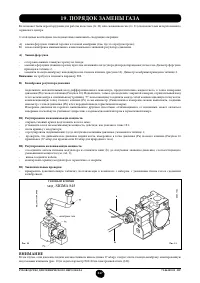

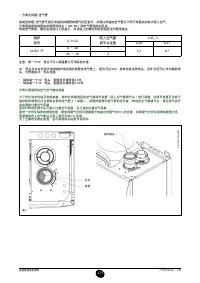

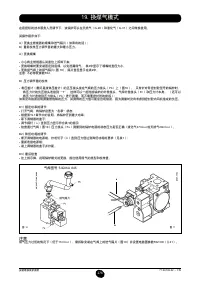

- 247 ПОРЯДОК ЗАМЕНЫ ГАЗА; газовый клапан

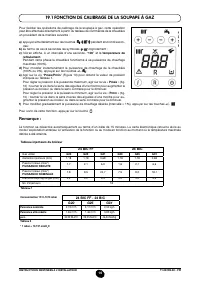

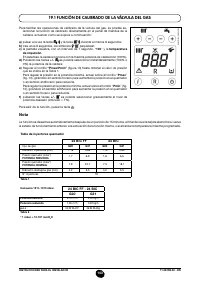

- 248 ФУНКЦИЯ КАЛИБРОВКИ ГАЗОВОГО КЛАПАНА; Примечание

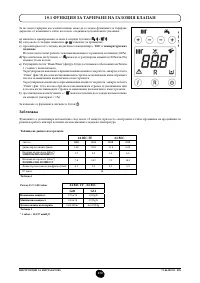

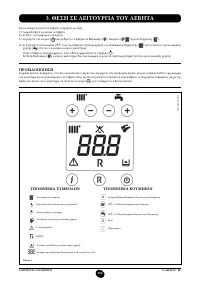

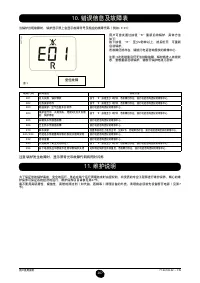

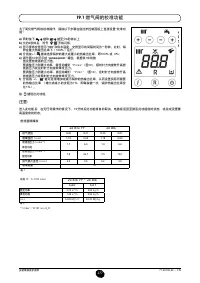

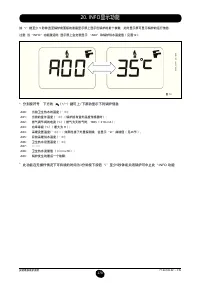

- 249 ВЫВОД ИНФОРМАЦИИ НА ДИСПЛЕЙ КОТЛА

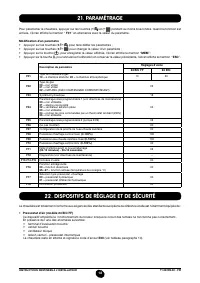

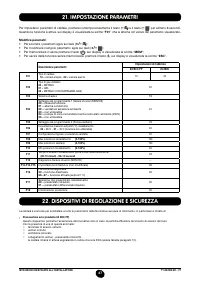

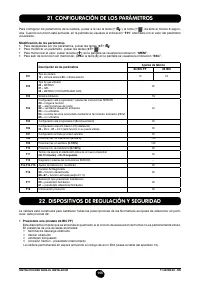

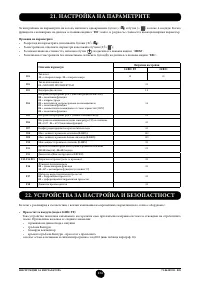

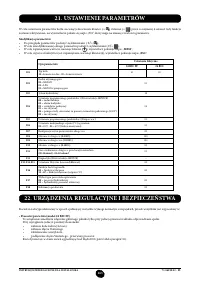

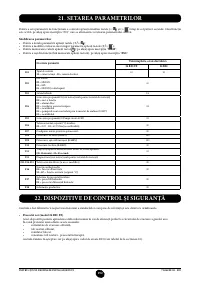

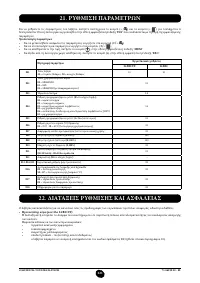

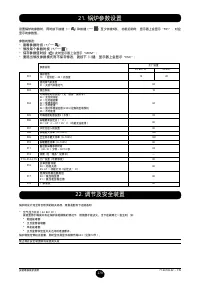

- 250 УСТАНОВКА ПАРАМЕТРОВ; УСТРОЙСТВА РЕГУЛИРОВАНИЯ И ПРЕДОХРАНИТЕЛЬНЫЕ УСТРОЙСТВА

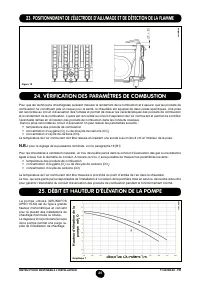

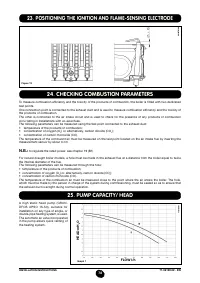

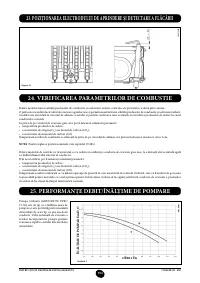

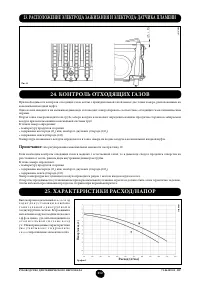

- 252 КОНТРОЛЬ ОТХОДЯЩИХ ГАЗОВ; ап

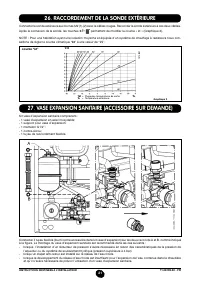

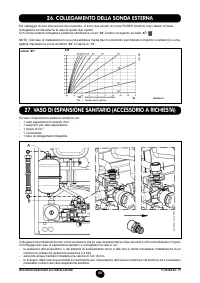

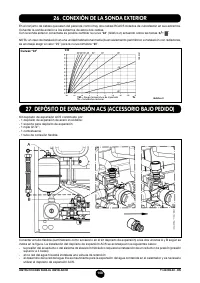

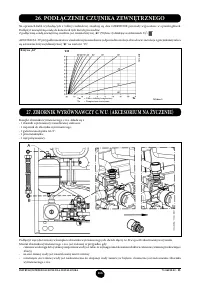

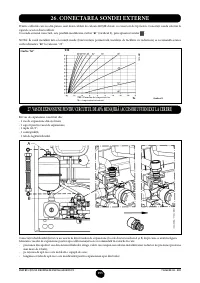

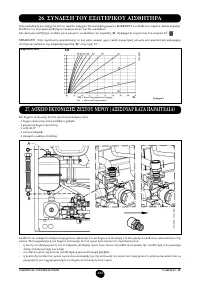

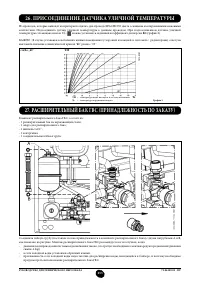

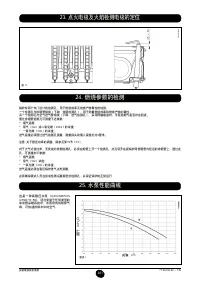

- 253 ПРИСОЕДИНЕНИЕ ДАТЧИКА УЛИЧНОЙ ТЕМПЕРАТУРЫ

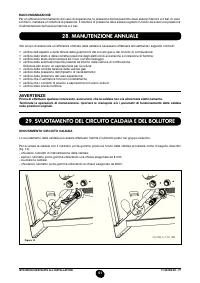

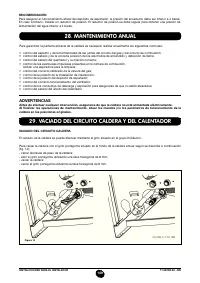

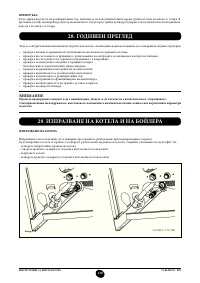

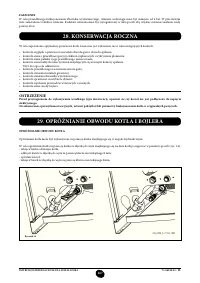

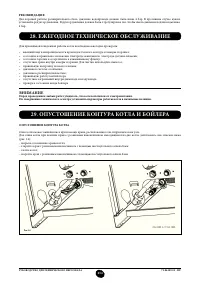

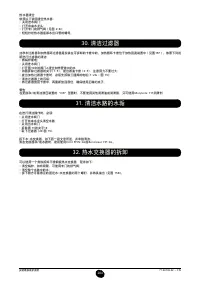

- 254 ЕЖЕГОДНОЕ ТЕХНИЧЕСКОЕ ОБСЛУЖИВАНИЕ; ОПУСТОШЕНИЕ КОНТУРА КОТЛА И БОЙЛЕРА

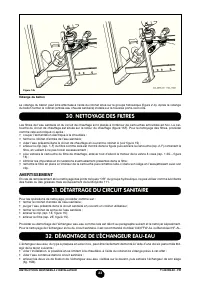

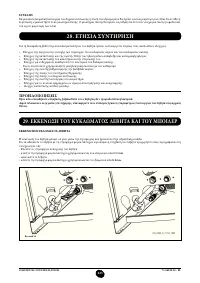

- 255 ОЧИСТКА ОТ ИЗВЕСТКОВОГО НАЛЕТА В СИСТЕМЕ ГВС

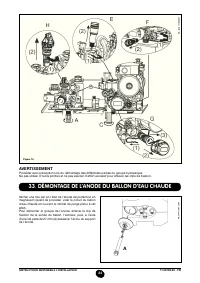

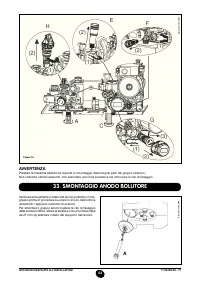

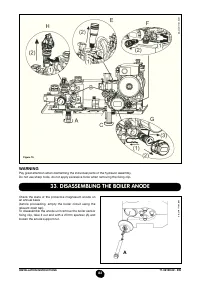

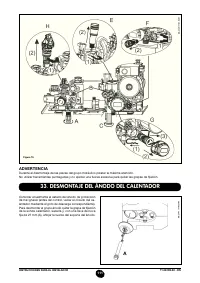

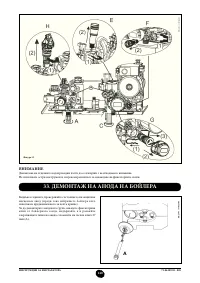

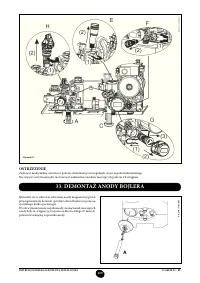

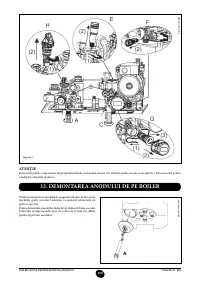

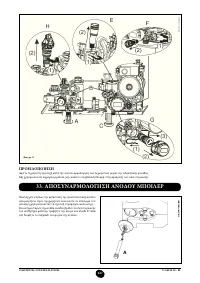

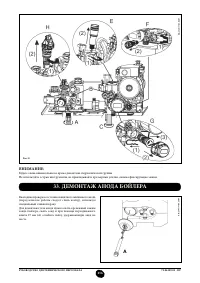

- 256 ДЕМОНТАЖ АНОДА БОЙЛЕРА

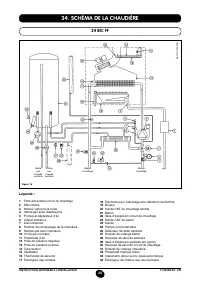

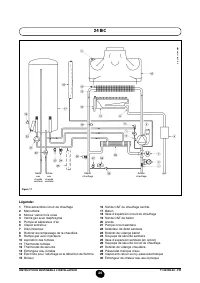

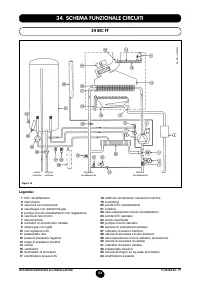

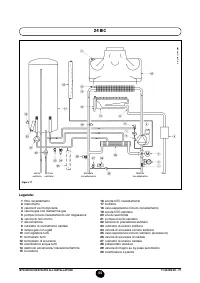

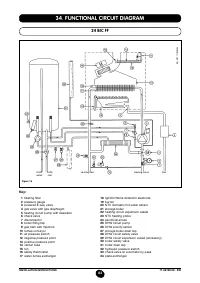

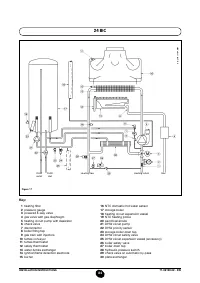

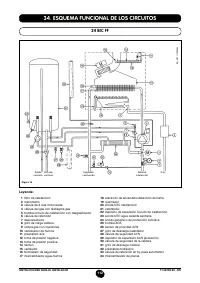

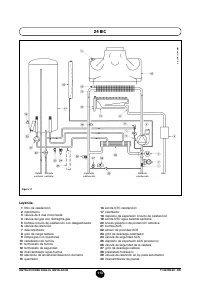

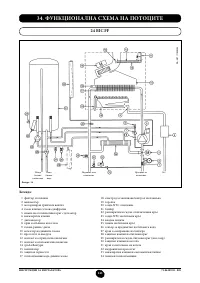

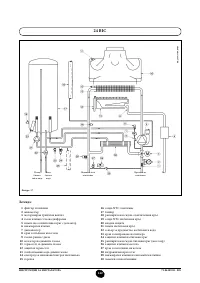

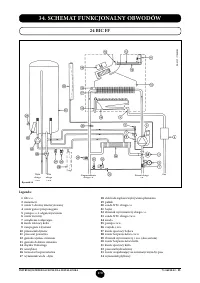

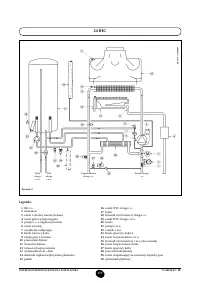

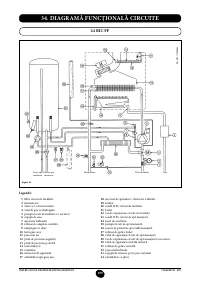

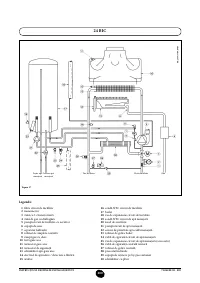

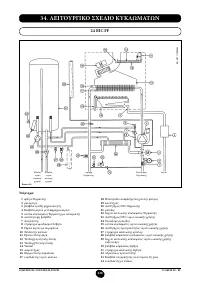

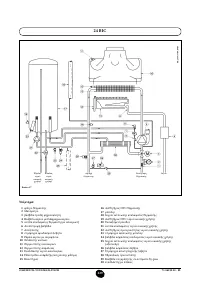

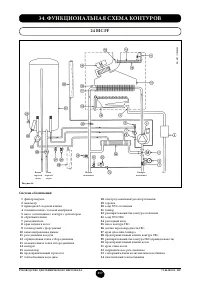

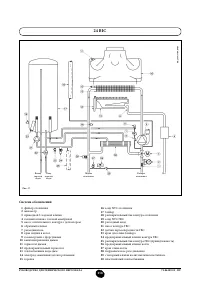

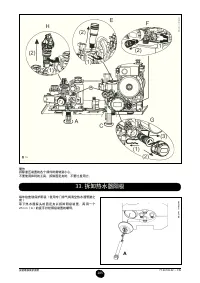

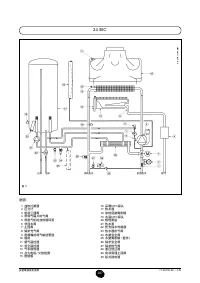

- 257 ФУНКЦИОНАЛЬНАЯ СХЕМА КОНТУРОВ

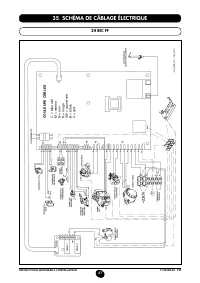

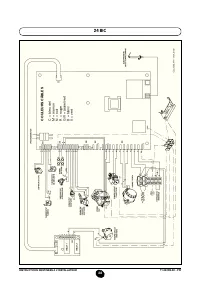

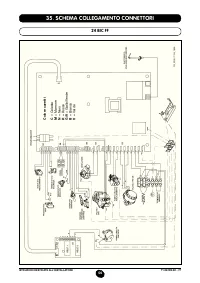

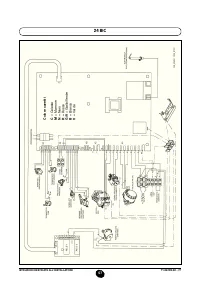

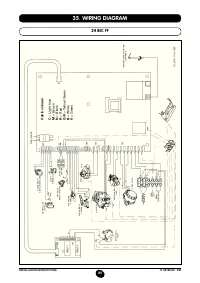

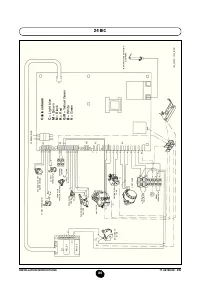

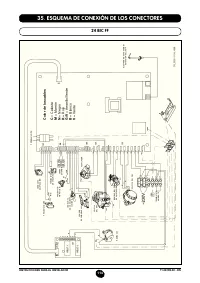

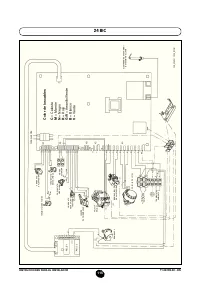

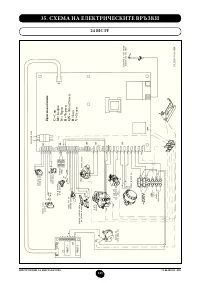

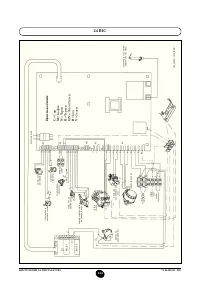

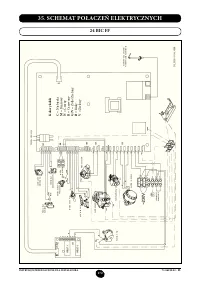

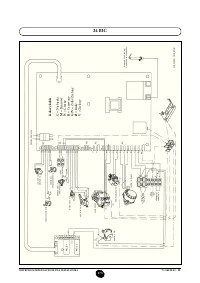

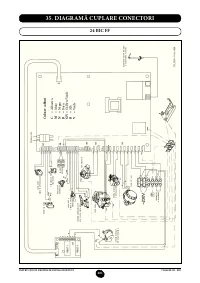

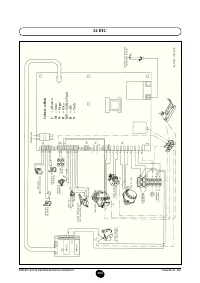

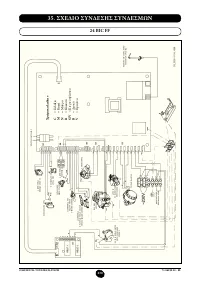

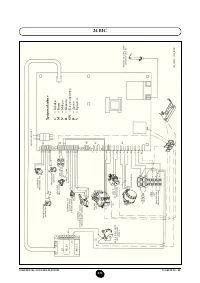

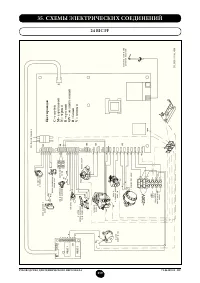

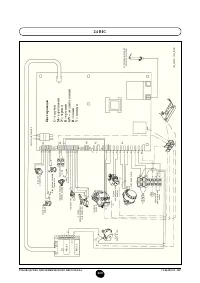

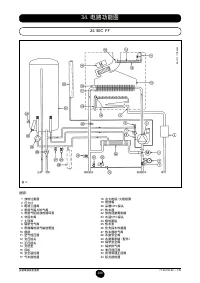

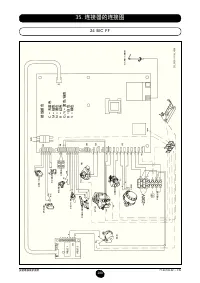

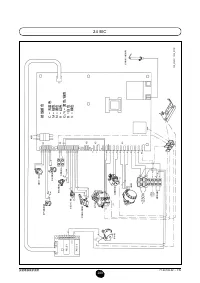

- 259 СХЕМЫ ЭЛЕКТРИЧЕСКИХ СОЕДИНЕНИЙ; Цв

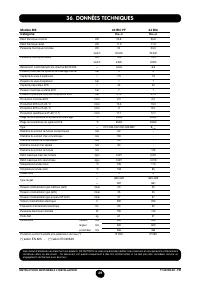

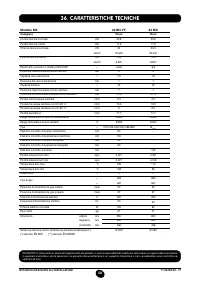

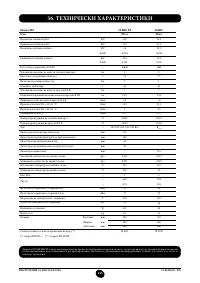

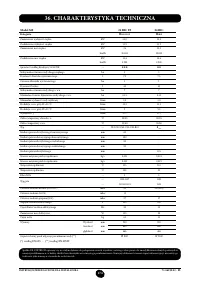

- 261 ТЕХНИЧЕСКИЕ ДАННЫЕ