Электропилы Bosch GCM 10 SD - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

36

| English

1 609 92A 0XL | (29.9.14)

Bosch Power Tools

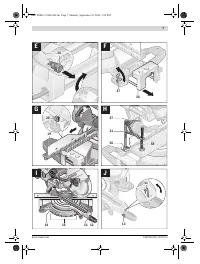

Checking and Adjusting the Basic Adjustment

Before any work on the machine itself, pull the mains

plug.

To ensure precise cuts, the basic adjustment of the machine

must be checked and adjusted as necessary after intensive use.

A certain level of experience and appropriate specialty tools

are required for this.

A Bosch after-sales service station will handle this mainte-

nance task quickly and reliably.

Setting the Standard Bevel Angle 0 ° (Vertical)

– Bring the machine into the transport position.

– Turn the saw table

16

to the 0 ° detent

15

. The lever

13

must be felt to engage in the detent.

The tool storage

42

must be removed for access to the cov-

ered set screws.

– For this, remove both the fastening screws

43

as well as

the fastening nut

44

.

Checking:

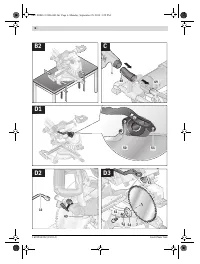

(see figure S1)

– Set an angle gauge to 90 ° and place it on the saw table

16

.

The leg of the angle gauge must be flush with the saw blade

7

over the complete length.

Adjusting:

(see figure S2)

– Loosen the lock lever

14

.

– Loosen set screws

64

and

65

with the supplied open-end

spanner

45

(10 mm).

– Loosen set screw

66

(approx. 3 turns) with the supplied

hex key

33

(4 mm).

– Screw set screw

63

(10 mm) in or out until the leg of the

angle gauge is flush with the saw blade over the complete

length.

– Retighten the lock lever

14

again.

Afterwards, tighten set screw

66

first, and then set screws

64

and

65

.

When the angle indicators

31

and

22

are not in line with the

0 ° marks of scale

30

after adjusting, loosen the fastening

screws of the angle indicators with the supplied cross-head

screwdriver

33

and align the angle indicators alongside the 0 °

marks.

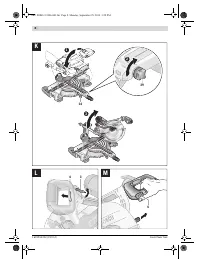

Setting the Standard 45 ° Bevel Angle (Leftward)

– Bring the power tool into the working position.

– Turn the saw table

16

to the 0 ° detent

15

. The lever

13

must be felt to engage in the detent.

– Pull the left fence extension

19

completely outward.

– Loosen the lock lever

14

and tilt the tool arm leftward to

the stop (45 °) by the handle

5

.

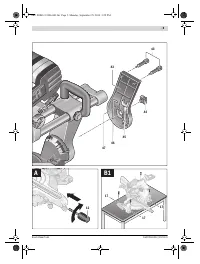

The tool storage

42

must be removed for access to the cov-

ered set screws.

– For this, remove both the fastening screws

43

as well as

the fastening nut

44

.

Checking:

(see figure T1)

– Set an angle gauge to 45 ° and place it on the saw table

16

.

The leg of the angle gauge must be flush with the saw blade

7

over the complete length.

Adjusting:

(see figure T2)

– Screw set screw

67

(10 mm) in or out until the leg of the

angle gauge is flush with the saw blade over the complete

length.

– Retighten the lock lever

14

again.

When the angle indicators

31

and

22

are not in line with the

45 ° marks of scale

30

after adjusting, firstly once more check

the 0 ° setting for the bevel angle and the angle indicators.

Then repeat the adjustment of the 45 ° bevel angle.

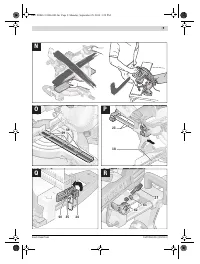

Setting the Standard 45 ° Bevel Angle (Rightward)

– Bring the power tool into the working position.

– Turn the saw table

16

to the 0 ° detent

15

. The lever

13

must be felt to engage in the detent.

– Pull the right fence extension

19

completely outward.

– Loosen the lock lever

14

.

– Lightly tilt the tool arm leftward out of the 0 ° position via

handle

5

and turn knob

39

until the bevel angle range

is indicated.

– Tilt the tool arm via handle

5

rightward to the stop (45 °).

The tool storage

42

must be removed for access to the cov-

ered set screws.

– For this, remove both the fastening screws

43

as well as

the fastening nut

44

.

Checking:

(see figure U1)

– Set an angle gauge to 135 ° and place it on the saw table

16

.

The leg of the angle gauge must be flush with the saw blade

7

over the complete length.

Adjusting:

(see figure U2)

– Guide the supplied hex key

46

(3 mm) from outside

through the smaller hole in the housing and insert it into

the covered set screw

68

.

– Screw the set screw in or out until the leg of the angle

gauge is flush with the saw blade over the complete length.

– Retighten the lock lever

14

again.

When the angle indicators

31

and

22

are not in line with the

45 ° marks of scale

30

after adjusting, firstly once more check

the 0 ° setting for the bevel angle and the angle indicators.

Then repeat the adjustment of the 45 ° bevel angle.

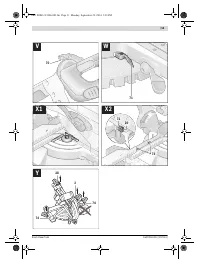

Adjusting the Clamping Force of Lock Lever 14

(see figure T2)

The clamping force of lock lever

14

can be readjusted.

Checking:

– The clamping force of the clamping lever must securely

hold the position of the tool arm at any bevel angle.

Adjusting:

– Loosen the lock lever

14

.

– Turn set screw

69

in anticlockwise direction with the sup-

plied open-end spanner

45

(17 mm) to reduce the clamp-

ing force, or increase the clamping force by turning in

clockwise direction.

– Adjust a vertical bevel angle, retighten lock lever

14

and

check if the desired clamping force has been reached.

0 – 45°

OBJ_BUCH-1128-003.book Page 36 Monday, September 29, 2014 12:25 PM

Содержание

- 238 Защищайте электроинструмент от дождя и сырости.

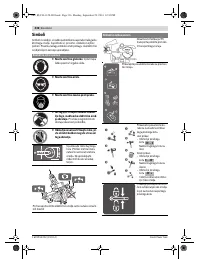

- 239 Держите Ваше рабочее место в чистоте.; Символы; Символы и их значение

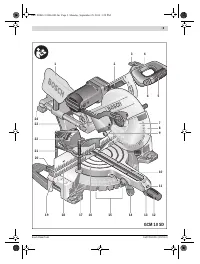

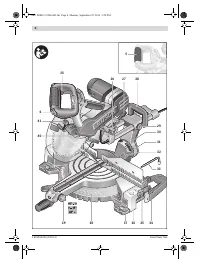

- 241 Описание продукта и услуг; Применение по назначению

- 242 Технические данные; Применяйте средства защиты органов слуха!; Заявление о соответствии; Сборка; Комплект поставки; Панельная пила; Размеры пильных дисков

- 243 Стационарный или временный монтаж; Монтаж на верстаке производства Bosch; Отсос пыли и стружки; Внешняя система пылеотсоса

- 244 Демонтаж пильного диска; Работа с инструментом; Подготовка к эксплуатации

- 245 Настройка вертикального угла распила; угол распила

- 246 Включение электроинструмента; Угол распила

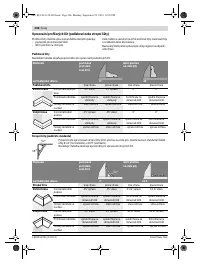

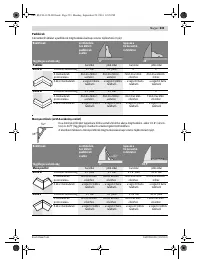

- 247 Резание с тяговым движением; Обработка профильных реек (плинтусов и потолочных планок); Плинтусы

- 248 Основные настройки – контроль и коррекция; Настройка угла наклона в 0 °

- 250 Настройка упорной планки; Техобслуживание и сервис; Техобслуживание и очистка; Очистка; Принадлежности

- 251 Россия; Утилизация