Электропилы Bosch GCM 10 SD - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

English |

33

Bosch Power Tools

1 609 92A 0XL | (29.9.14)

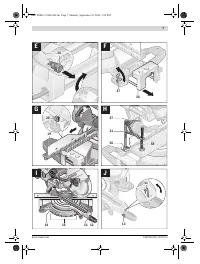

Bevel angle range

– Pull the left fence extension

19

completely outward. (see

“Extending the Fence”, page 32)

– Loosen the lock lever

14

.

– Tilt the tool arm leftward via handle

5

until the angle indica-

tor

31

indicates the desired bevel angle.

– Hold the tool arm in this position and retighten the clamp-

ing lever

14

.

The clamping force of the clamping lever must securely

hold the position of the tool arm at any bevel angle.

Bevel angle range

(see figure K)

– Pull the right fence extension

19

completely outward.(see

“Extending the Fence”, page 32)

– Loosen the lock lever

14

.

– Lightly tilt the tool arm leftward out of the 0 ° position via

handle

5

and turn knob

39

until the desired bevel angle

range is indicated.

– Tilt the tool arm via handle

5

to the right until angle indica-

tor

22

indicates the desired bevel angle.

– Hold the tool arm in this position and retighten the clamp-

ing lever

14

.

The clamping force of the clamping lever must securely

hold the position of the tool arm at any bevel angle.

Standard 0 ° Bevel Angle

To enable simple and swift resetting of the standard 0 ° bevel

angle, knob

39

will engage in the

bevel angle range.

– Tilt the tool arm from right to left over the 0 ° position.

Bevel angle range

– Pull both fence extensions

19

completely outward.(see

“Extending the Fence”, page 32)

– Loosen the lock lever

14

.

– Lightly tilt the tool arm leftward out of the 0 ° position via

handle

5

and turn knob

39

until the desired bevel angle

range is indicated.

– Tilt the tool arm via handle

5

to the left or right until angle

indicator

31

or

22

indicate the desired bevel angle.

– Hold the tool arm in this position and retighten the clamp-

ing lever

14

.

The clamping force of the clamping lever must securely

hold the position of the tool arm at any bevel angle.

Standard 33.9 ° Bevel Angle

–

Standard angle 33.9 °:

Pull adjustment knob

32

completely outward and turn it by

90 °. Now tilt the tool arm via the handle

5

until the tool arm

can be heard to engage.

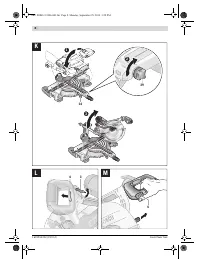

Adjusting the Handle (see figure L)

For a more convenient hand position, the handle

5

can be

turned to 4 different positions.

– Loosen clamp

3

.

– Grasp and pull tongue

4

outward, then turn handle

5

until

it engages in the desired position.

– Let go of tongue

4

again and lock clamp

3

.

Starting Operation

Observe correct mains voltage! The voltage of the pow-

er source must agree with the voltage specified on the

nameplate of the machine. Power tools marked with

230 V can also be operated with 220 V.

Switching On (see figure M)

– To

start

the machine, press the On/Off switch

25

and keep

it pressed.

Note:

For safety reasons, the On/Off switch

25

cannot be

locked; it must remain pressed during the entire operation.

The locking lever

41

will only disengage the retracting blade

guard

8

after pressing button

6

, so that the tool arm can be

lowered.

– For

sawing

, you must press button

6

in addition to actuat-

ing the On/Off switch.

To save energy, only switch the power tool on when using it.

Switching Off

– To

switch off

the machine, release the On/Off switch

25

.

Working Advice

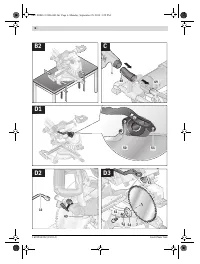

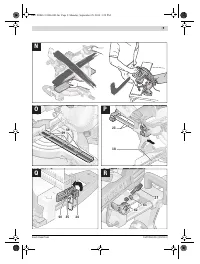

General Sawing Instructions

For all cuts, it must first be ensured that the saw blade

at no time can come in contact with the fence, screw

clamps or other machine parts. Remove any mounted

auxiliary stops or adjust them accordingly.

Protect the saw blade against impact and shock. Do not sub-

ject the saw blade to lateral pressure.

Do not saw warped/bent workpieces. The workpiece must

always have a straight edge to face against the fence.

Long workpieces must be underlaid or supported at their free

end.

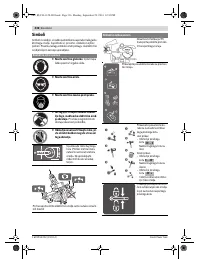

Position of the Operator (see figure N)

Do not stand in a line with the saw blade in front of the

machine. Always stand aside of the saw blade.

This pro-

tects your body against possible kickback.

– Keep hands, fingers and arms away from the rotating saw

blade.

– Do not cross your arms when operating the tool arm.

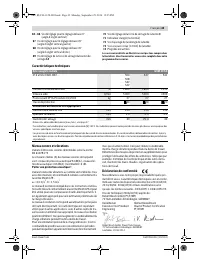

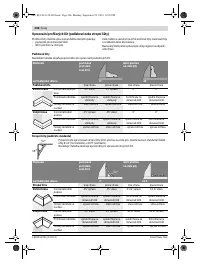

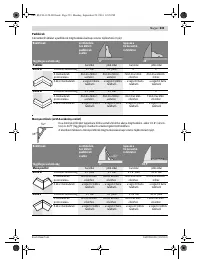

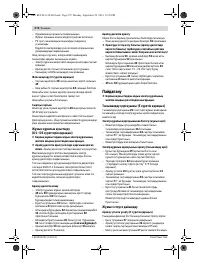

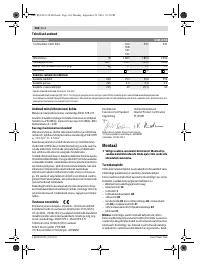

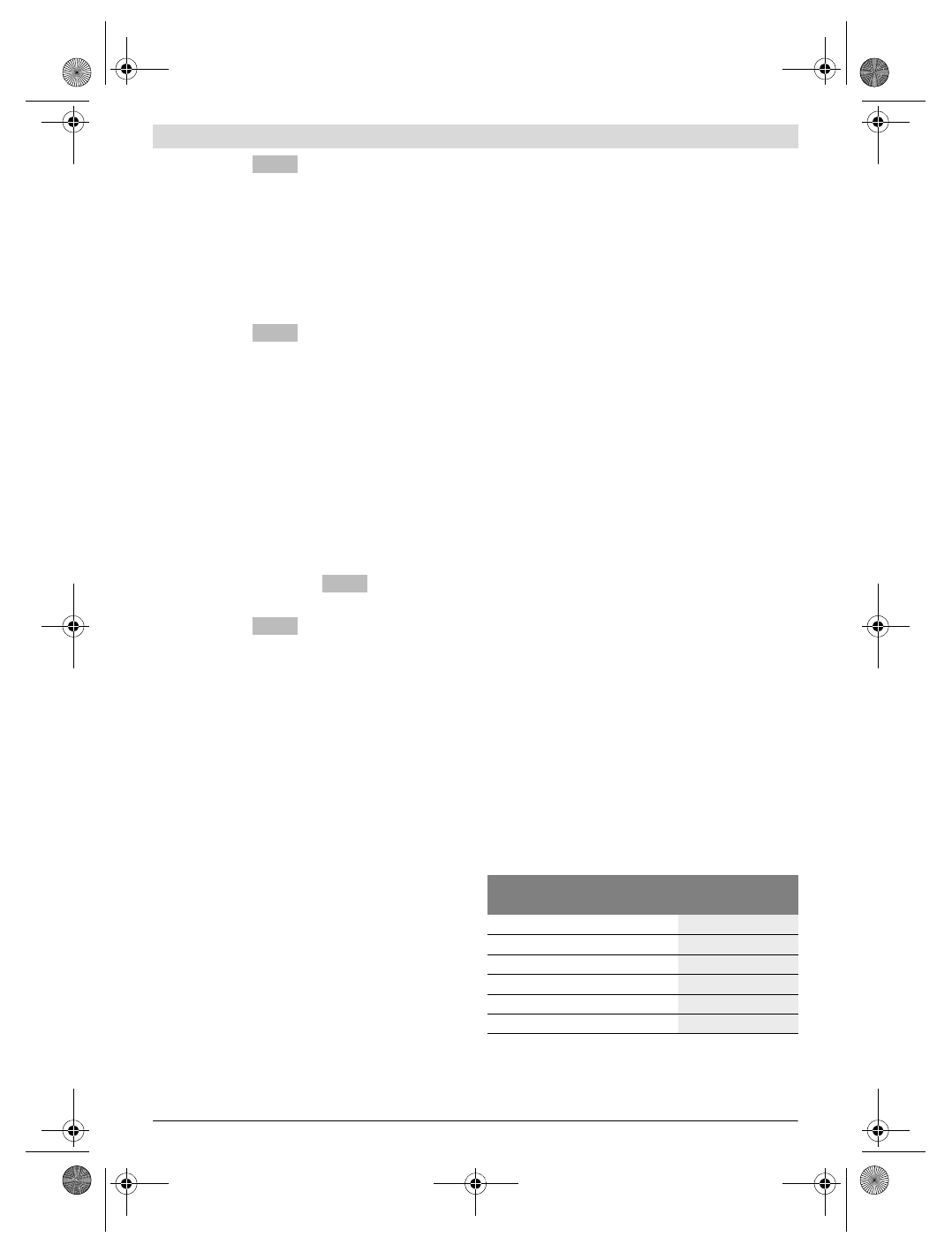

Permissible Workpiece Dimensions

Maximum

workpiece sizes:

Minimum

workpiece sizes (= all workpieces that can be

clamped left or right from the saw blade with the provided

quick-action clamp

21

): 145 x 40 mm (length x width)

Cutting depth, max.

(0 °/0 °): 85 mm

45°– 0

0 – 45°

45°– 0

45°+

Mitre/Bevel Angle

Height x Width [mm]

Horizontal

Vertical

0 °

0 °

85 x 305

45 °

0 °

85 x 216

0 °

45 ° (leftward)

50 x 305

0 °

45 ° (rightward)

32 x 305

45 °

45 ° (leftward)

50 x 216

45 °

45 ° (rightward)

32 x 216

OBJ_BUCH-1128-003.book Page 33 Monday, September 29, 2014 12:25 PM

Содержание

- 238 Защищайте электроинструмент от дождя и сырости.

- 239 Держите Ваше рабочее место в чистоте.; Символы; Символы и их значение

- 241 Описание продукта и услуг; Применение по назначению

- 242 Технические данные; Применяйте средства защиты органов слуха!; Заявление о соответствии; Сборка; Комплект поставки; Панельная пила; Размеры пильных дисков

- 243 Стационарный или временный монтаж; Монтаж на верстаке производства Bosch; Отсос пыли и стружки; Внешняя система пылеотсоса

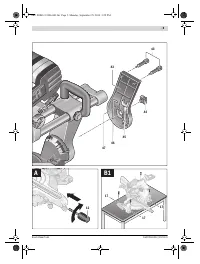

- 244 Демонтаж пильного диска; Работа с инструментом; Подготовка к эксплуатации

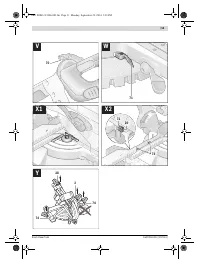

- 245 Настройка вертикального угла распила; угол распила

- 246 Включение электроинструмента; Угол распила

- 247 Резание с тяговым движением; Обработка профильных реек (плинтусов и потолочных планок); Плинтусы

- 248 Основные настройки – контроль и коррекция; Настройка угла наклона в 0 °

- 250 Настройка упорной планки; Техобслуживание и сервис; Техобслуживание и очистка; Очистка; Принадлежности

- 251 Россия; Утилизация