Генераторы Telwin THUNDER 220 AC HONDA 825001 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

- 7 -

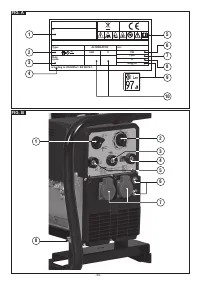

2- Selector for adjusting the 3 welding ranges and for adjusting the

output voltage of the auxiliary sockets.

3- Negative quick connector (-) for welding cable connection.

4- Positive quick connector (+) for welding cable connection.

5- Auxiliary socket voltmeter.

6- Circuit-breaker.

7- Single-phase socket.

8- Three-phase socket.

9- Hole for earth connection.

5. INSTALLATION

WARNING! CARRY OUT ALL INSTALLATION AND

ELECTRIC CONNECTION OPERATIONS WITH THE ENGINE-

DRIVEN WELDING MACHINE RIGOROUSLY SWITCHED OFF.

THE ELECTRIC CONNECTIONS MUST ONLY BE CARRIED OUT

BY EXPERT OR QUALIFIED TECHNICIANS.

PREPARATION

Unpack the engine-driven welding machine and assemble the

separate parts included in the package.

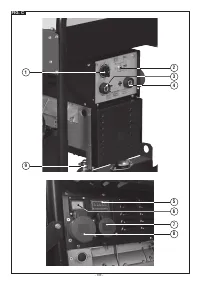

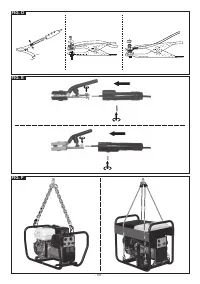

Return cable-clamp assembly

Fig. D

Electrode-holder clamp-welding cable assembly

Fig. E

HOW TO LIFT THE ENGINE-DRIVEN WELDING MACHINE

The engine-driven welding machine MUST be lifted as shown in Fig.

F.

This is valid for both initial installation and for the entire life of the

engine-driven welding machine.

Note: The wire feeder, gas bottle, cables and interconnecting and

supply cables must be removed before lifting the engine-driven

welding machine. Make sure the lifting cables, belts or chains do not

damage the engine-driven welding machine accessory parts.

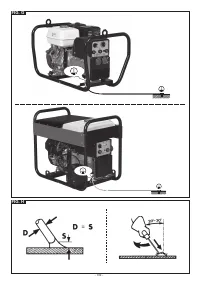

POSITIONING THE ENGINE-DRIVEN WELDING MACHINE

Make sure the engine-driven welding machine is positioned in a

place where the cooling air inlets and outlets cannot be obstructed;

at the same time make sure that conductive dust, corrosive vapours,

humidity etc. cannot be drawn into the machine.

Leave at least 1m of free space all around the engine-driven welding

machine.

WARNING! Position the engine-driven welding machine

on a level surface with sufficient load-bearing capacity, so that it

cannot topple or shift dangerously.

MACHINE EARTHING

To prevent electric shocks caused by faulty user equipment,

the machine must be connected using a fixed earthing system and

through the relative terminal.

Fig. G

THE ELECTRIC CONNECTIONS MUST ONLY BE CARRIED OUT

BY EXPERT OR QUALIFIED TECHNICIANS.

INTERNAL COMBUSTION ENGINE

Regarding:

- checks before use;

- engine starting;

- engine use;

- engine stopping;

refer to the USER MANUAL of the internal combustion engine

producer.

WELDING CIRCUIT CONNECTIONS

WARNING! BEFORE CARRYING OUT THE FOLLOWING

CONNECTIONS MAKE SURE THE ENGINE-DRIVEN WELDING

MACHINE IS SWITCHED OFF.

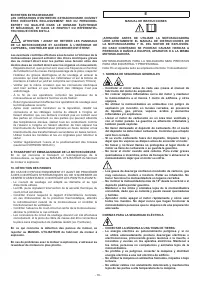

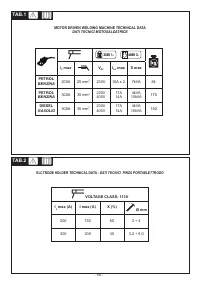

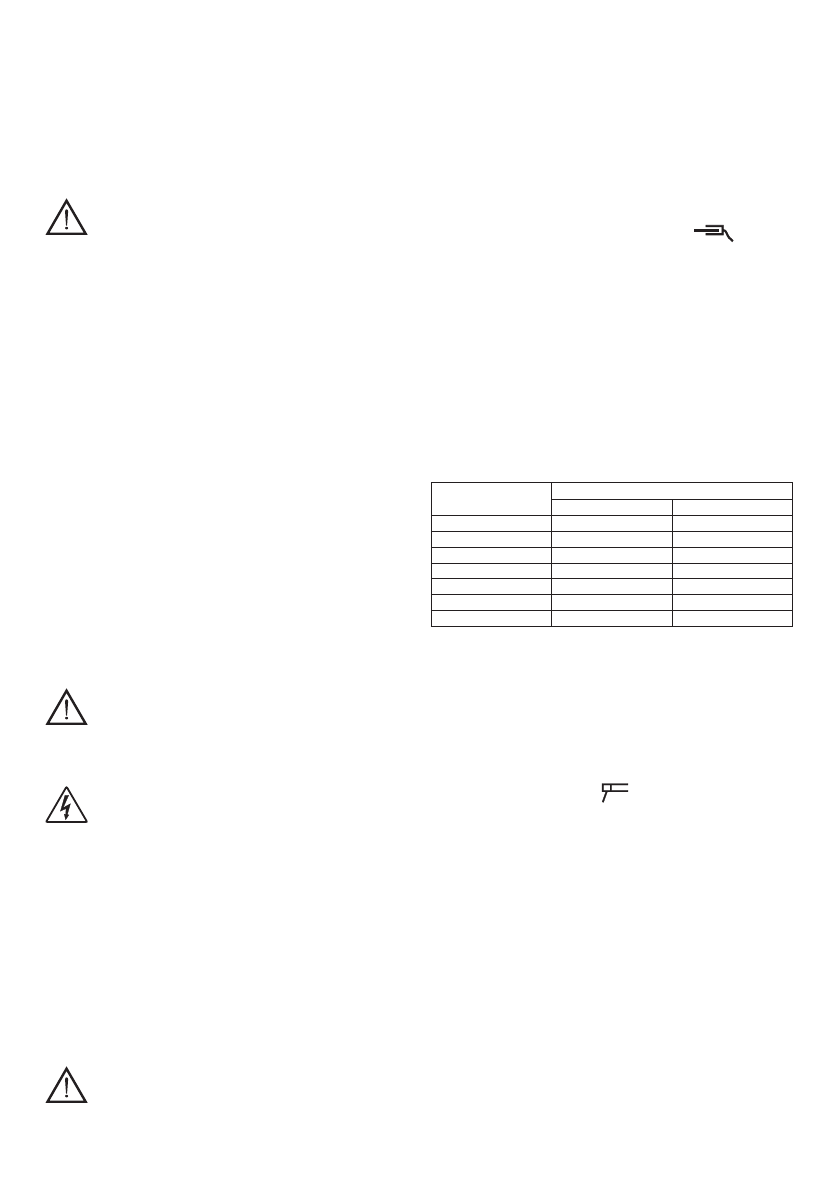

The Table

(TAB. 1)

shows the recommended sizes of the welding

cables (in mm2), according to the maximum current output from the

engine-driven welding machine.

Electrode holder clamp-welding cable connection

There is a special clamp on the terminal that tightens the uncovered

part of the electrode.

Connect this cable to the clamp with the symbol (60A-120A) or

(130A-200A) or (+).

Connecting the welding current return cable

There is a special clamp on the terminal that must be connected to

the workpiece or to the metal bench on which is it positioned, and as

close as possible to the joint being worked.

Connect this cable to the clamp with the symbol

or (-).

Recommendations:

- Screw the welding cable connectors right down into the quick

couplings, so as to ensure perfect electrical contact; otherwise, the

connectors will overheat, wear rapidly and become inefficient.

- Use welding cables that are as short as possible.

- Do not use metal structures that are not part of the workpiece to

substitute the welding current return cable; this could be dangerous

and produce an unsatisfactory weld.

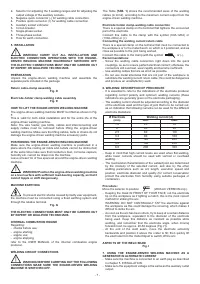

6. WELDING: DESCRIPTION OF PROCEDURE

- It is essential to refer to the indications of the electrode producer

regarding correct polarity and optimum welding currents (these

indications are generally given on the electrode packaging).

- The welding current should be adjusted according to the diameter

of the electrode used and the type of joint that is to be carried out;

as an indication the following currents can be used for the different

electrode diameters:

Ø Electrode

(mm)

Welding current (A)

min.

max.

1.6

25

50

2

40

80

2.5

60

110

3.2

80

160

4.0

120

200

5.0

160

230

6.0

200

330

- Keep in mind that high current levels are used when flat welding,

while lower currents should be used with vertical or overhead

welding.

- The mechanical characteristics of the welded joint are determined

by the intensity of the selected current, and also by the other

welding parameters such as arc length, execution speed and

position, electrode diameter and quality (for correct conservation

protect the electrodes from humidity using suitable packages or

containers).

Procedure:

Move the selector to position

(200A AC VERSION only).

- Keeping the mask IN FRONT OF YOUR FACE, rub the electrode

tip on the workpiece as if lighting a match; this is the most correct

method for striking the arc.

WARNING: DO NOT CONTINUALLY TAP the electrode against

the workpiece as this could damage the covering, which makes it

difficult to strike the arc.

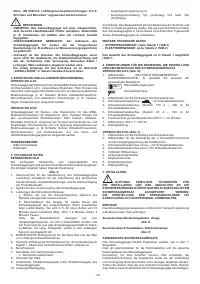

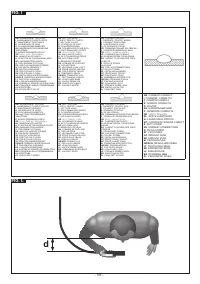

- As soon as the arc has been struck, try to keep at a certain distance

from the workpiece, equivalent to the diameter of the electrode

being used. Keep this distance as constant as possible while

welding, and remember that the electrode angle, when moving

forward must, be approx. 20-30 degrees (Fig. H).

- At the end of the weld seam, move the electrode extremity

backwards and position it above the crater to fill; then quickly lift

the electrode from the melted liquid to switch off the arc.

ASPECTS OF THE WELD SEAM

Fig. I

7. USING THE ENGINE-DRIVEN WELDING MACHINE AS A

GENERATOR IN ALTERNATE CURRENT

- Make sure the machine is connected to an earth peg as described

in chapter 5. INSTALLATION.

- Make sure the equipment voltage is the same as the auxiliary outlet

output.