Генераторы Telwin THUNDER 220 AC HONDA 825001 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

- 6 -

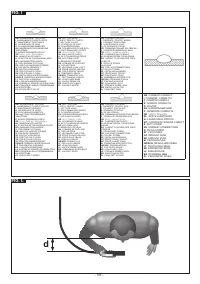

- Fix the two welding cables as close to each other as possible.

- Operators must keep their heads and trunks as far away as

possible from the welding circuit.

- Operators must never wind the welding cables around their

body.

- Operators must never keep their body in the centre of the

welding circuit while they weld. Operators must keep both

cables on the same side of their body.

- Connect the welding current return cable to the piece to be

welded, as close as possible to the join being made/welding

spot.

- Never weld while remaining close to, sitting on or leaning

against the engine-driven welding machine (minimum

distance: 50 cm).

- Do not leave ferromagnetic objects near the welding circuit.

- Minimum distance d = 20 cm (Fig. L)

- Class A equipment:

This engine-driven welding machine satisfies the requirements

of the product technical standards for exclusive use in industrial

environments for professional purposes.

ADDITIONAL PRECAUTIONS

- WELDING OPERATIONS:

- In environments with increased risk of electric shock;

- In confined spaces;

- In the presence of inflammable or explosive material;

MUST ALWAYS be evaluated in advance by an “Expert

supervisor” and must always be carried out in the presence

of other people trained in emergency procedures.

The technical protection means described in sections 7.10;

A.8; A.10. of “Part 9: Installation and use” of the “EN 60974-9:

Apparatus for arc welding” Directive MUST ALWAYS be used.

- Welding should NEVER be allowed if the operator is above

floor level, unless a safety platform is used.

- VOLTAGE BETWEEN THE ELECTRODE HOLDERS OR

TORCHES: when working with more than one welding

machine on a single piece, or on several pieces that are

connected electrically, dangerous no-load voltages may build

up between two different electrode holders or torches and

may reach double the allowed limit.

It is essential for an expert coordinator to use measuring

instruments to determine whether there is a risk, and to

be able to adopt adequate safety measures as indicated

in section 7.9 of the EN 60974-9: Apparatus for arc welding

Directive. Part 9: Installation and use”.

RESIDUAL RISKS

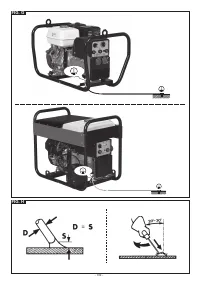

- TOPPLING: position the engine-driven welding machine on a

horizontal surface that is suitable for supporting the weight;

if the surface is not horizontal (e.g. sloped or broken flooring,

etc...) the welding machine can topple.

- IMPROPER USE: it is dangerous to use the engine-driven

welding machine for any purpose other than that for which it

is intended (e.g. defrosting piping from the water system).

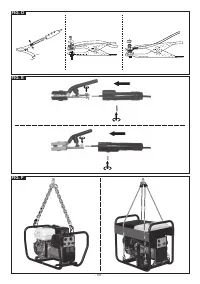

- It is forbidden to lift the engine-driven welding machine unless

the gas bottles, wire feeder and all the interconnecting or

power cables/piping (if present) have been removed.

The only permitted way to lift the machine is described in the

“INSTALLATION” section of this handbook.

2. INTRODUCTION AND GENERAL DESCRIPTION

200A AC VERSION

Petrol engine-driven welding machine for MMA electrode welding in

(AC) alternate current. Electrodes: rutile. It can be used as a single-

phase AC current generator for powering all types of electric tool

(e.g. sanders, drills, dowel hole drills, demolishers, etc.) and electric

devices (e.g. lights, saws, compressors, etc.).

300A DC VERSION

Petrol or diesel engine-driven welding machine for MMA electrode

welding in (DC) direct current. It can be used with many different

electrodes: rutile, basic, cellulose, stainless, aluminium, cast iron,

etc. It can be used as a single-phase and three-phase AC current

generator for powering all types of electric tool (e.g. sanders,

drills, dowel hole drills, demolishers, etc.) , compressors, neon and

incandescent lighting systems, etc.

ACCESSORIES SUPPLIED ON REQUEST:

- MMA welding kit

- Wheel kit.

3. TECHNICAL DATA

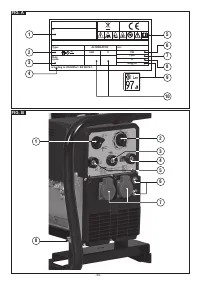

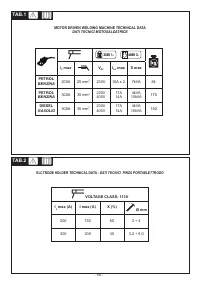

DATA PLATE

The main data regarding engine-driven welding machine performance

and use are given briefly in the characteristics plate with the following

meaning:

Fig. A

1- Serial number for engine-driven welding machine identification

(essential for servicing, requesting spare parts, searching for

product origin).

2- Symbol representing the internal structure of the engine-driven

welding machine.

3- Welding circuit performance:

- I

2

: Currents that can be supplied by the welding machine

during welding.

- X : Intermittence ratio: indicates the time during which the

engine-driven welding machine can supply the corresponding

current (same column). Expressed in %, on the basis of a

10-minute cycle (e.g. 60% = 6 minutes work, 4 minutes rest;

and so on).

If the use factors (referred to a room temperature of 40°C)

are exceeded, the thermostatic safeguard cuts in (the

engine-driven welding machine remains in stand-by until its

temperature returns within the permitted limits).

4- EUROPEAN Standard of reference for safety and for the

construction of arc welding machines.

5- Symbols that refer to safety regulations, the meanings of which

are given in chapter 1 “General safety regulations”.

6- Nominal frequency.

7- Internal combustion engine characteristic data:

- n : Rated load speed.

8- Casing protection grade.

9- Sound power (or pressure) level guaranteed by the engine-

driven welding machine.

10- Auxiliary power output:

- Nominal output voltage (V).

- Nominal output power 1ph (single-phase) and/or 3ph (three-

phase).

Note: The meaning of the symbols and figures given in the example

plate shown are indicative; the exact values of the technical data

of the engine-driven welding machine in your possession must be

looked for directly on the plate of the machine itself.

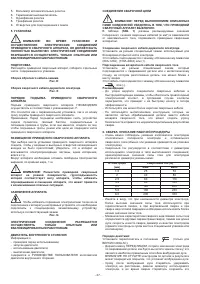

OTHER TECHNICAL INFORMATION:

- ENGINE-DRIVEN WELDING MACHINE: see table 1 (TAB.1)

- ELECTRIC HOLDER CLAMP: see table 2 (TAB.2)

The weight of the engine-driven welding machine is given in

table 1 (TAB.1)

4. ENGINE-DRIVEN WELDING MACHINE CONTROL DEVICES,

ADJUSTMENT AND CONNECTION

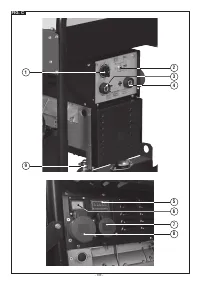

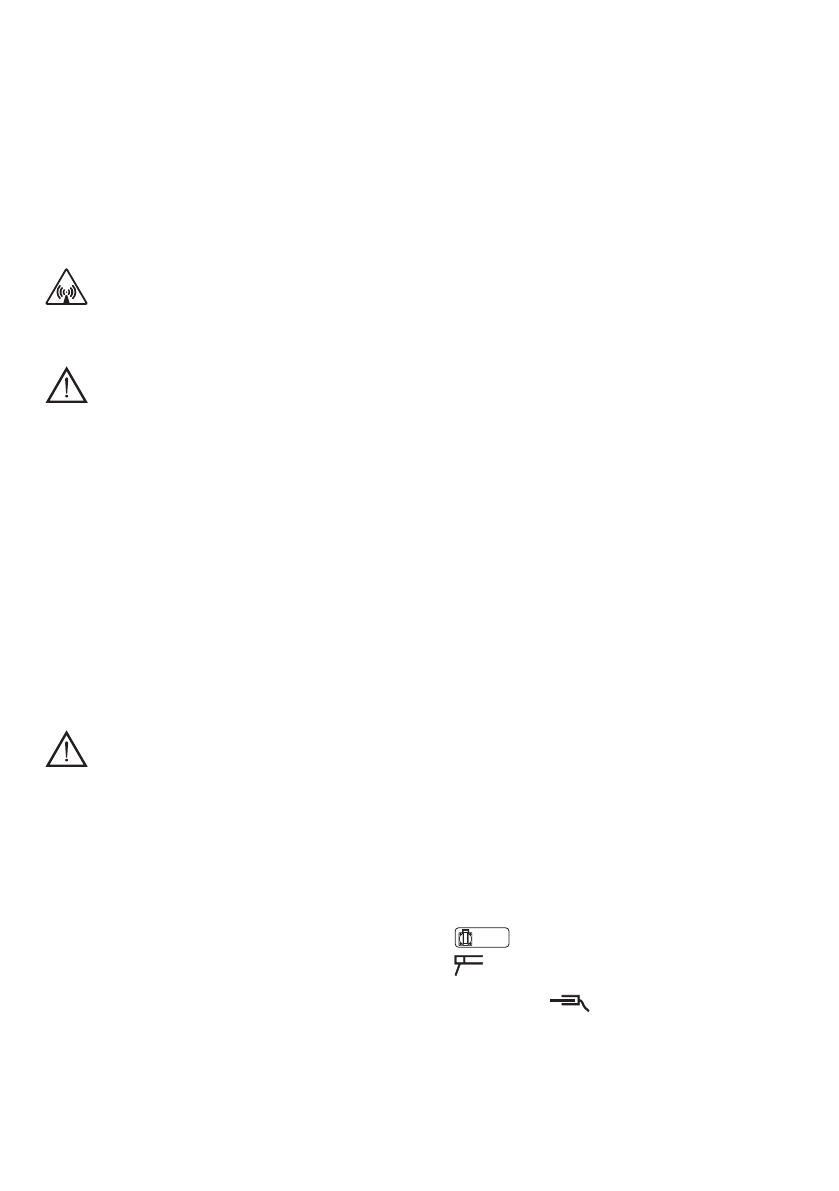

200A DC VERSION (Fig. B)

1- ALTERNATE CURRENT-WELDING MACHINE GENERATOR

selector. Use to select the operation mode to be used:

230V 1~

Alternate current generator.

Welding machine.

2- Selector switch for adjusting the welding current.

3- Quick connector

for welding cable connection.

4- Quick connector (range 130A – 200A) for welding cable

connection

5- Quick connector (range 60A – 120A) for welding cable connection

6- Thermostatic safeguard (one for each 230V 1~ connector).

7- Auxiliary connectors 230V 1~ (50Hz).

8- Hole for earth connection.

300A DC VERSION (Fig. C)

1- Selector switch for adjusting the welding current