Генераторы Telwin MOTOINVERTER 264D CE LOMBARDINI 815980 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

An expert coordinator must use measuring instruments to

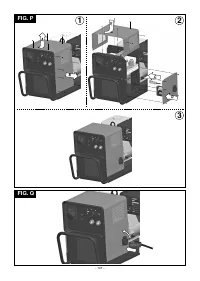

(TAB.1)

determine whether a risk exists and should take suitable

protective measures as indicated in section 5.9 of the "IEC

4. DESCRIPTION OF THE ENGINE-DRIVEN WELDER

TECHNICAL SPECIFICATION or CLC/TS 62081".

The engine-driven welder consists of an engine that drives a

permanent magnet high frequency alternator which is used to supply

power to a power module from which the welding current and auxiliary

RESIDUAL RISKS

current are taken.

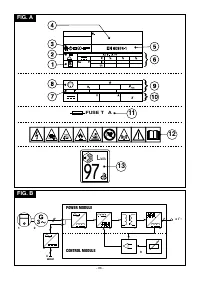

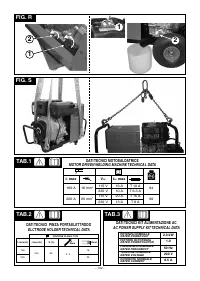

Fig. B

- IMPROPER USE: it is dangerous to use the engine-driven

1-

Engine.

welder for any work other than that for which it is intended (e.g.

2-

High frequency alternator.

defrosting frozen water pipes).

3-

Rectifier.

4-

Direct current auxiliary power outlet.

- Never lift the machine without first disconnecting and

5-

Input for 3-phase generator, rectifier unit and levelling capacitors.

removing all interconnection and power supply cables and

6-

Transistor switching bridge (IGBT's) and drivers; commutes the

piping.

rectified voltage into high frequency alternating voltage and

The only permitted way to lift the machine is that described in

adjusts the power according to the required welding

the "INSTALLATION" section of this handbook.

current/voltage.

7-

High frequency transformer: the primary winding is powered with

- It is forbidden to drag the engine-driven machine on streets.

the voltage converted by block 6; its function is to adapt the voltage

and current to the values needed for the arc welding procedure and

2. INTRODUCTION AND GENERAL DESCRIPTION

at the same time to form galvanic isolation of the welding circuit

This engine-driven welder is a power source for arc welding, built

from the power supply line

specifically for direct current (DC) MMA welding.

8-

Secondary rectifier bridge with levelling inductance: commutes the

The properties of this (INVERTER) adjustment system, such as high-

alternating voltage/current supplied by the secondary winding to

speed precise adjustment, mean that the engine-driven welder

very low ripple direct voltage/current.

produces excellent quality welds with coated electrodes (rutile, acid,

9-

Control and adjustment electronics: for instantaneous monitoring

basic, cellulose).

of transitory welding current values and comparison with setting

The machine also has an auxiliary outlet

for a direct current power

made by the operator; modulates the control impulses from the

supply to tools with universal motors (brushes)

such as angle

IGBT drivers used for adjustments.

grinders and drills.

Determines the dynamic response of the current while the

electrode is melting (instantaneous short circuits) and supervises

OPTIONAL ACCESSORIES:

the safety systems.

- MMA welding kit.

- TIG welding kit.

CONTROL AND ADJUSTMENT DEVICES AND CONNECTION TO

- Argon bottle adapter.

THE ENGINE-DRIVEN WELDER

- Pressure reduction valve.

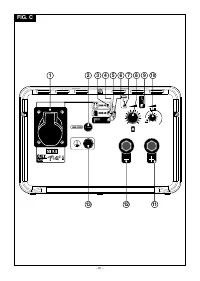

Fig. C

- TIG torch.

1-

Auxiliary power outlet 230V DC (direct current).

- Wheels kit (Standard for the model with I max=200A).

2

2-

Auxiliary outlet fuse.

- AC power supply kit (only model with I max = 160A, I max = 200A).

2

2

3- GREEN LED:

when lit this indicates operation in direct current

generator mode.

3. TECHNICAL DATA

4- GREEN LED:

when lit this indicates operation in alternating

RATING PLATE

current (AC) generator mode. The AC power supply kit is supplied

The most important information regarding use and performance of the

as an optional accessory.

engine-driven welder are summarised on the rating plate and have the

5- GREEN LED:

when lit indicates operation in welding machine

following meanings:

mode.

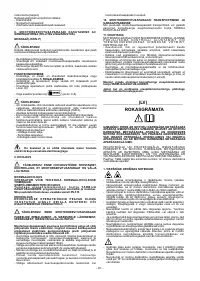

Fig. A

6- Selector switch for DIRECT CURRENT GENERATOR AC

1

- Symbol S: means that it is possible to carry out welding operations

GENERATOR WELDING MACHINE.

Used to select the desired

in environments with a heightened risk of electric shock (e.g. close

operating mode:

to large metal objects).

2

- Symbol for intended welding procedure.

Direct current generator;

3

- Symbol indicating the internal structure of the welding machine.

4

- Serial number identifying the welding machine (essential for

Alternating current generator;

servicing and repairs, when ordering spare parts and identifying

the origin of the product).

5

- EUROPEAN standard of reference for the construction and safety

Welding machine.

of arc welding machines.

7- RED LED:

normally off, when on indicates overheating in the

6

- Performance of welding circuit:

alternator which shuts down both the welding current and the

- U : maximum no-load voltage.

0

auxiliary current. The machine remains switched on but does not

- I /U : Normalised current and corresponding voltage that may be

2

2

supply any current until a normal temperature is reached. Reset is

supplied by the welding machine during welding.

automatic.

- X : Duty cycle: indicates the time for which the welding machine is

8-

Welding current adjustment potentiometer with graduated scale in

able to supply the corresponding current (same column). It is

Amps.; used for adjustment, also while welding.

expressed as %, based on a cycle of 10 minutes (e.g. 60% = 6

9 - YELLOW LED:

normally off, when on it indicates a fault that has

minutes work, 4 minutes pause; and so on).

shut down the welding current due to triggering of the following

If the utilisation factors (referred to a surrounding temperature of

safeguards:

40°C) are exceeded, the thermal relay will trigger (the engine-

- Thermal relay:

the temperature inside the engine-driven welder

driven welder will go into standby mode until the temperature

is too high. The machine stays on but does not supply any

returns within the accepted limits).

current until a normal temperature is reached. Reset is

- A/V-A/V: Indicates the adjustment range of the welding current

automatic.

(minimum-maximum) for the corresponding arc voltage.

- ANTI STICK safeguard:

automatically shuts down the welding

7

- Protection rating of case.

current if the electrode sticks to the material being welded, so

8

- Symbol for engine.

that it can be removed manually without ruining the electrode-

9

- Specifications for engine:

holder clamp.

- n: Rated load speed.

- Engine overspeed safeguard:

shuts down the welding current

- n : Rated idling speed.

0

supply until the engine speed returns to the rated values.

- P

: Maximum power of engine

1max

10- Function selector potentiometer and arc-force adjustment:

10

-Auxiliary power outlet:

- Symbol for direct current.

(

TIG welding). In this position the potentiometer enables TIG

- Rated output voltage.

welding with scratch strike. HOT START and ARC-FORCE are

- Rated output current.

disabled.

- Duty cycle.

11

-Size of delayed action fuse to be used to protect the auxiliary

(

MMA welding). Positioning the potentiometer between 0

outlet.

and 100% gives an easy start (HOT START) and it is possibile to

12

-Symbols referring to safety standards, the meanings of which are

adjust the ARC-FORCE for all types of electrodes. At very low

given in section 1 "General safety rules".

values an optimal welding dynamic is obtained for “soft”

13

-Guaranteed sound power level for the engine-driven welder.

electrodes (e.g. rutile, stainless steel), at high values an optimal

welding dynamic is obtained for “hard” electrodes (e.g. acid, basic,

Note: The rating plate shown is just an example to show the meanings

cellulose).

of the symbols and figures; the exact technical specifications for your

11-

Positive quick connection (+) for connecting the welding cable.

welding machine should be read directly from the rating plate on the

12-

Negative quick connection (-) for connecting the welding cable.

engine-driven welder itself

13-

Terminal for earth connection.

OTHER TECHNICAL DATA:

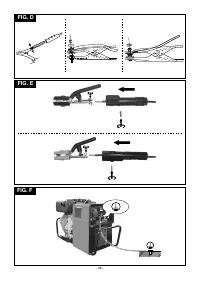

5. INSTALLATION

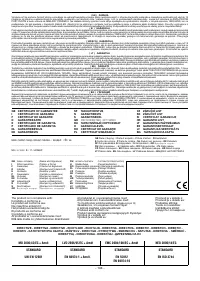

- ENGINE-DRIVEN WELDER: see table 1 (TAB.1)

________________________________________________________________________________

- ELECTRODE-HOLDER CLAMP: see table 2 (TAB.2)

- AC POWER SUPPLY KIT: see table 3 (TAB.3).

WARNING! ALL INSTALLATION OPERATIONS AND

The weight of the engine-driven welder is shown in table 1

- 4 -