Мойки высокого давления Karcher CB 2 23 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

-

20

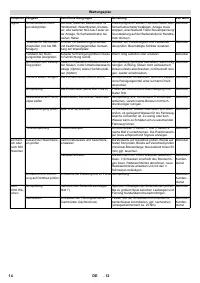

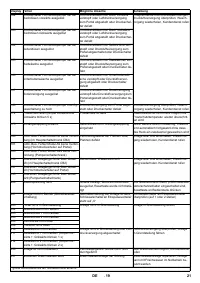

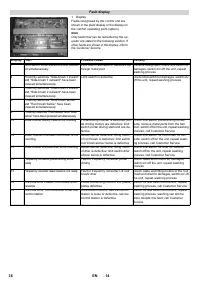

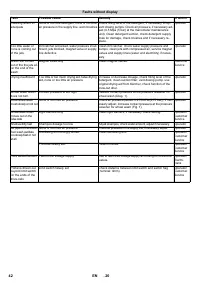

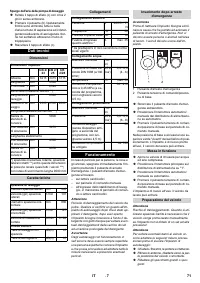

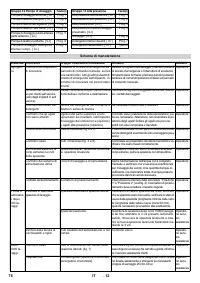

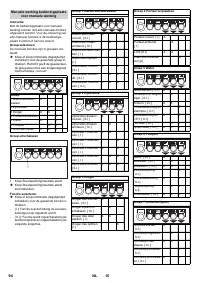

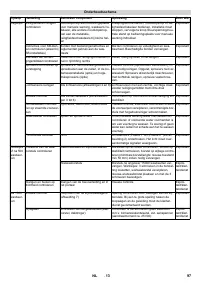

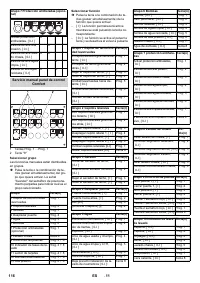

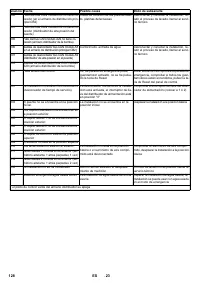

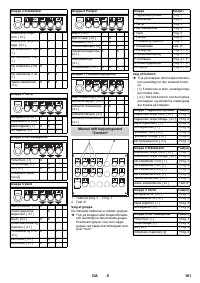

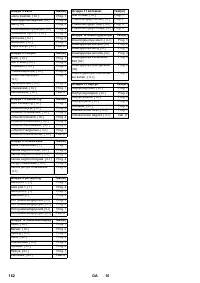

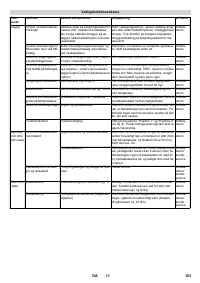

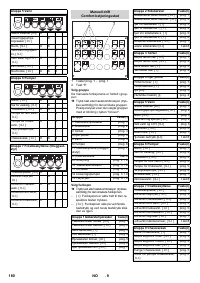

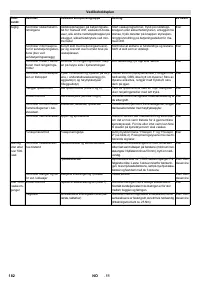

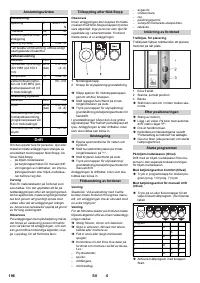

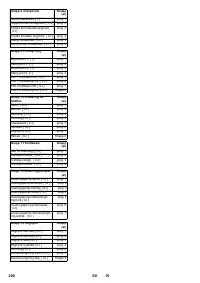

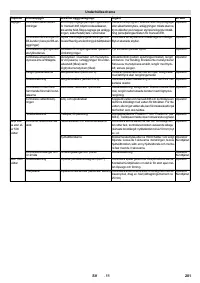

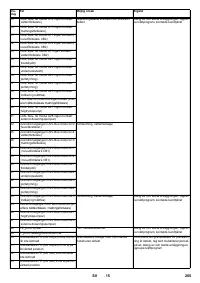

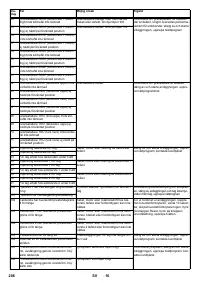

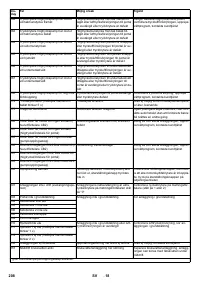

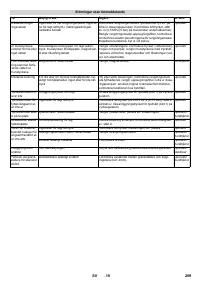

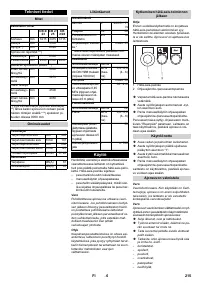

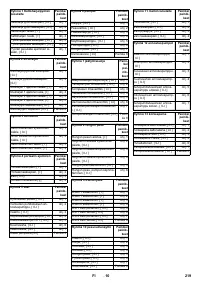

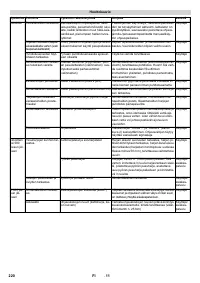

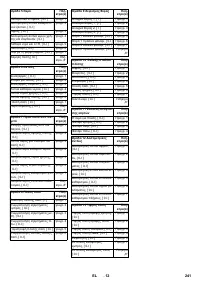

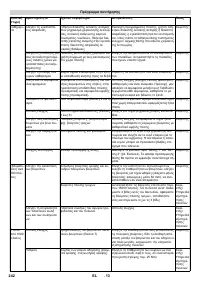

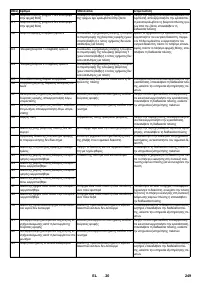

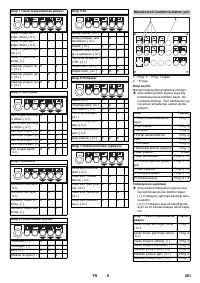

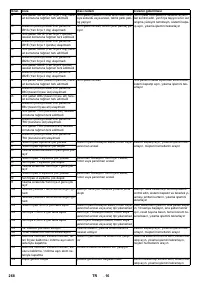

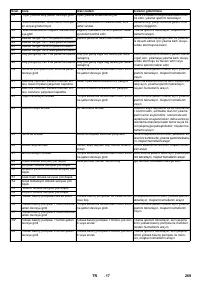

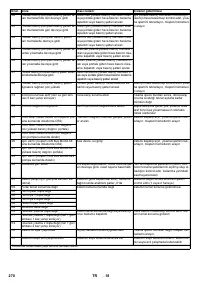

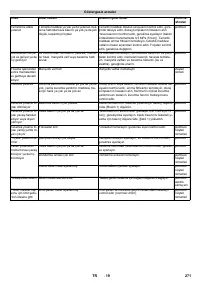

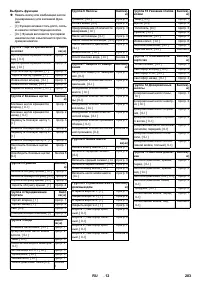

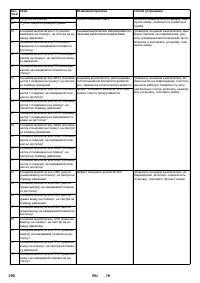

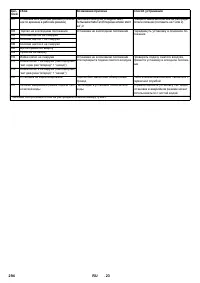

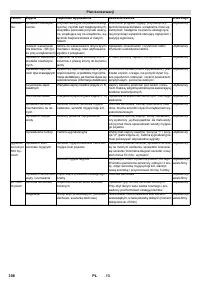

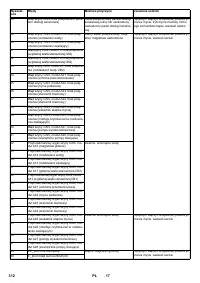

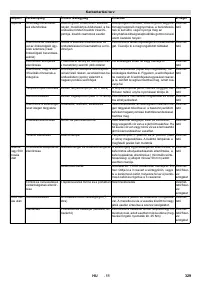

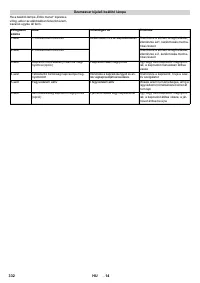

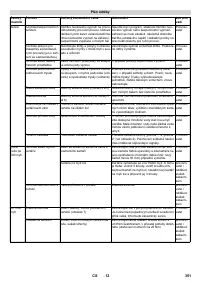

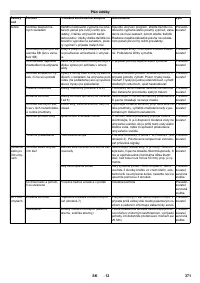

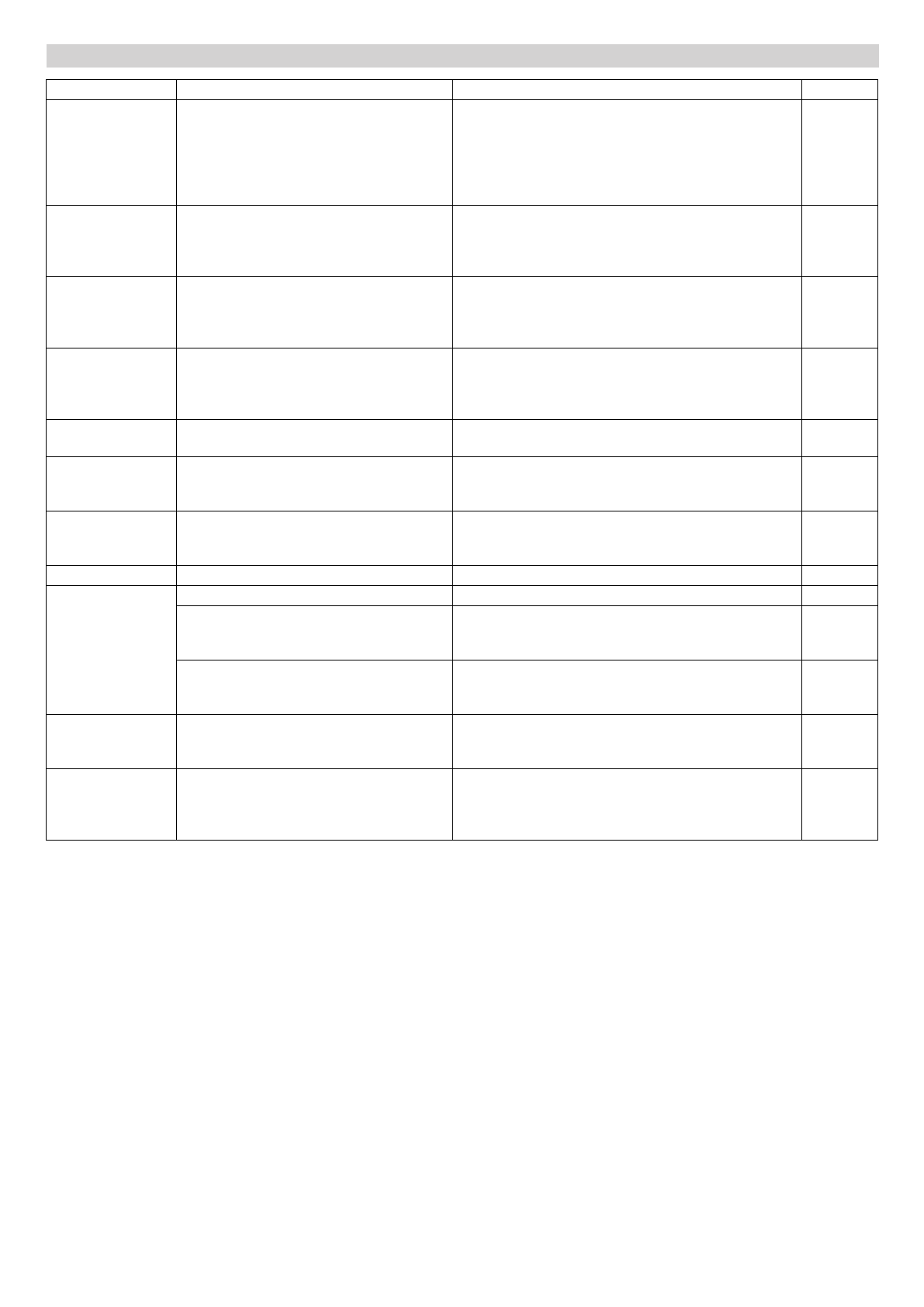

Faults without display

Fault

Possible cause

Remedy

of whom

Cleaning effect in-

adequate

None or too little detergent, none or too little

air pressure in the supply line, worn brushes

Check filling level of the detergent; if necessary fill up;

vent dosing pumps. Check air pressure, if necessary ad-

just (0.5 Mpa (5 bar) at the manometer maintenance

unit). Clean detergent suction, check detergent supply

lines for damage, check brushes and if necessary re-

place.

Operator

Too little water or

none is coming out

of the jets.

Dirt catcher is blocked, water pressure insuf-

ficient, jets blocked, magnet valve or supply

line defective

Clean dirt catcher, check water supply pressure and

pumps, clean jets with compressed air, service magnet

valves and supply lines (water und electricity) if neces-

sary.

Operator

Water still comes

out of the the jets af-

ter the end of the

wash

Magnet valve dirty

Clean magnet valves.

Customer

Service

Drying insufficient

Too little or too much drying aid, false drying

aid, none or too little air pressure

Increase or decrease dosage, check filling level of the

detergent, clean suction filter, vent dosing pump, use

original drying aid from Kärcher, check function of the

blow-out drier.

Operator

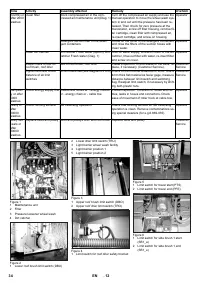

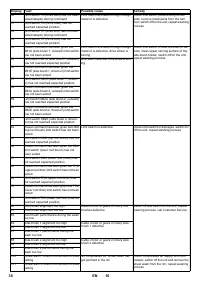

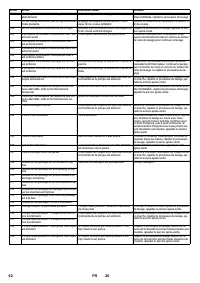

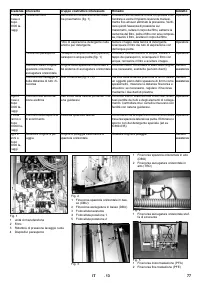

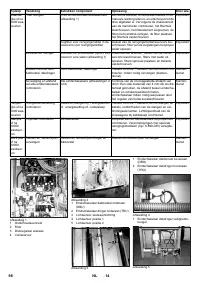

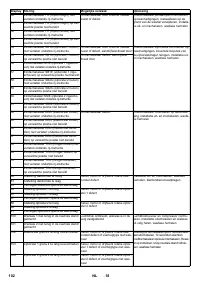

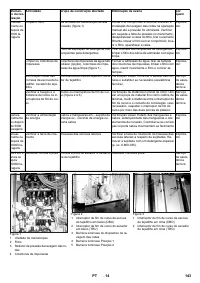

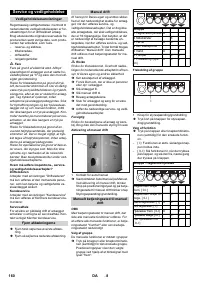

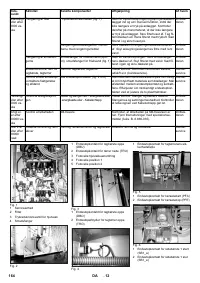

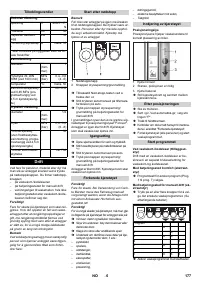

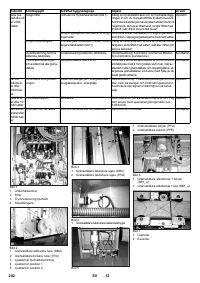

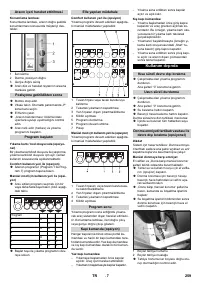

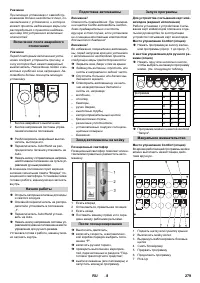

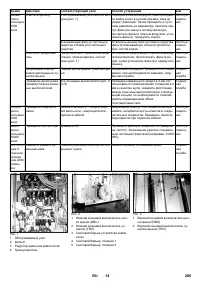

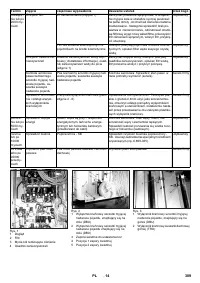

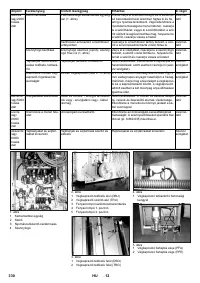

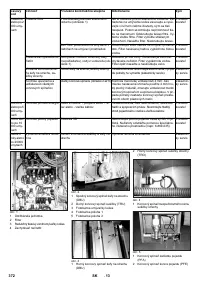

Wheel wash brush

does not turn.

Contact pressure is too high

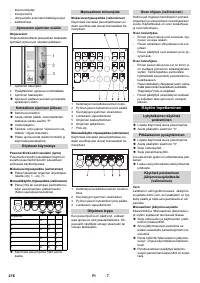

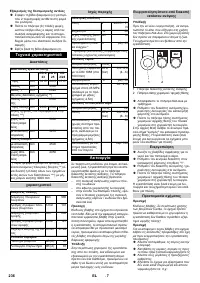

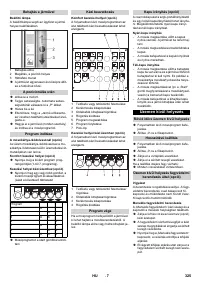

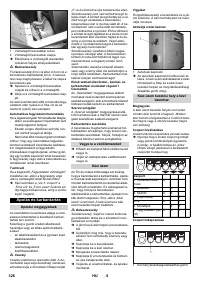

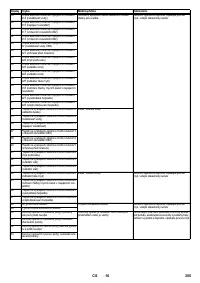

Reduce contact pressure at the pressure lessener for

wheel wash (Diag. 1).

Operator

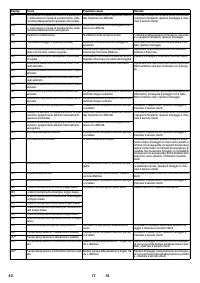

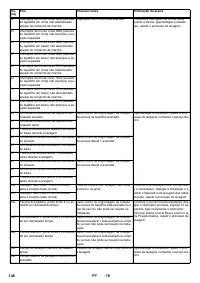

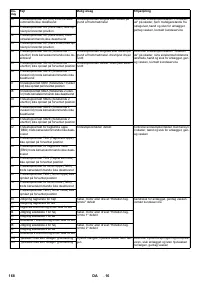

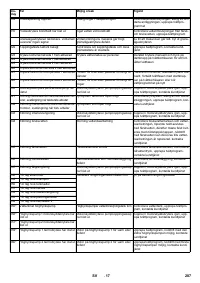

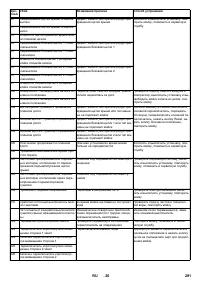

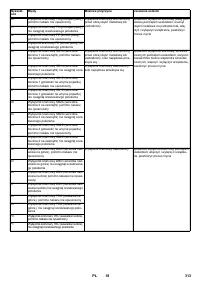

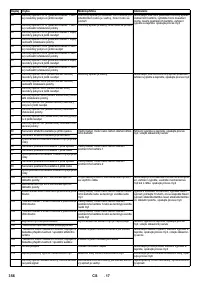

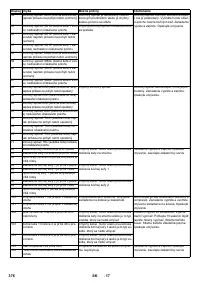

Move wheel wash

brush slowly or not out

None or too little air pressure

Check air pressure (about. 0.275 MPa (2.75 bar)), if nec-

essary adjust, increase contact pressure at the pressure

lessener for wheel wash (Fig. 1).

Operator

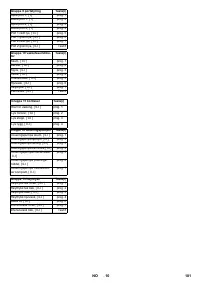

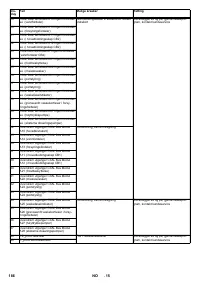

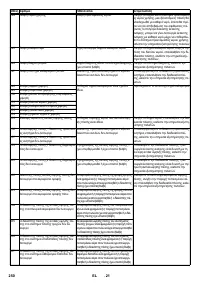

Wheel wash brush

moves out on the

false side

Light barriers dirty

Clean light barriers, if necessary check setting.

Operator/

Customer

Service

Brushes dirty fast

Shampoo dosage too low

Adjust shampoo, check water amount, adjust if necessary.

Operator

Jet pipes of the under-

floor wash oscillate

too slowly/fast or not

at all.

None or too little air pressure

Check air pressure in the supply line, if necessary adjust.

Operator

Oscillating unit strongly dirtied.

Clean oscillating unit.

Operator/

Customer

Service

Throttles falsely set.

Reset throttles.

Operator/

Customer

Service

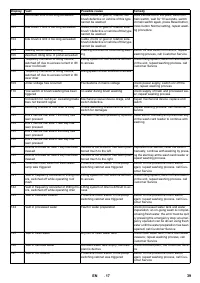

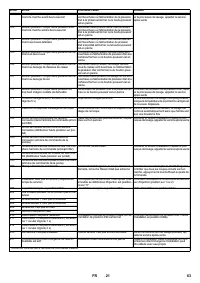

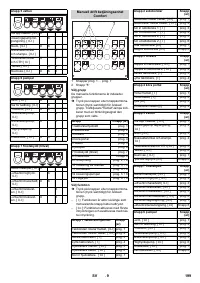

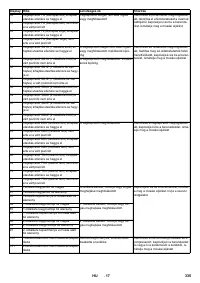

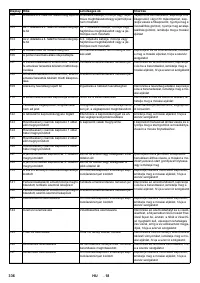

Plant without function Fault in the voltage supply

See to fault-free voltage supply according to connection

values.

Operator/

Electri-

cians

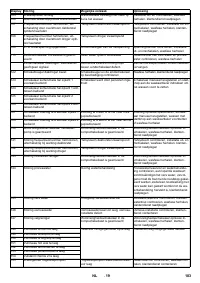

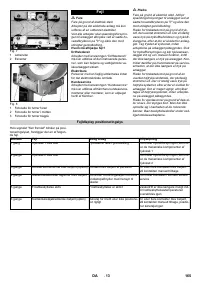

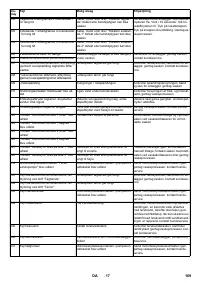

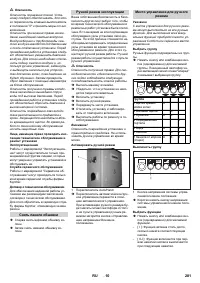

Portal is driven out

beyond limit switch

for the ends of the

drive-rails

Limit switch falsely set

Check distance between limit switch and switch flag

(nominal: 4mm).

Operator/

Customer

Service

42

EN