Мойки высокого давления Karcher CB 2 23 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

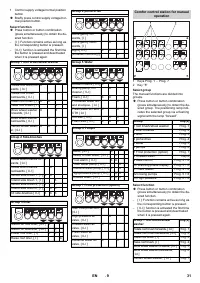

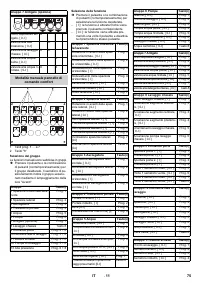

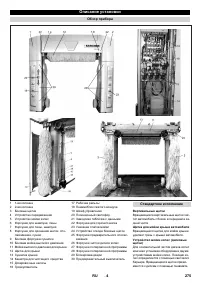

-

13

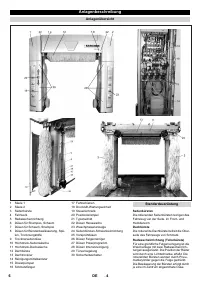

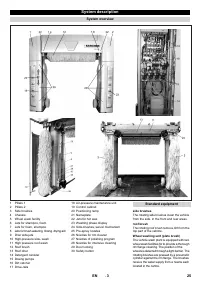

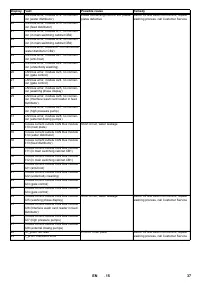

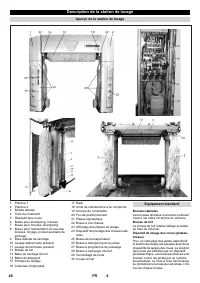

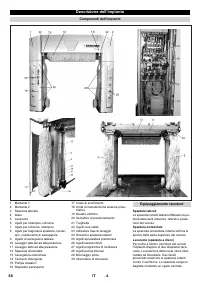

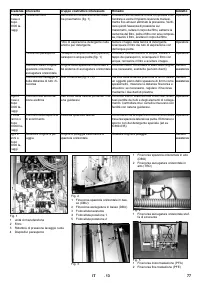

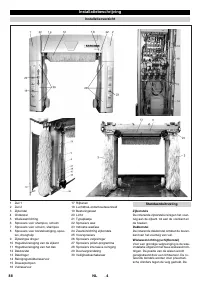

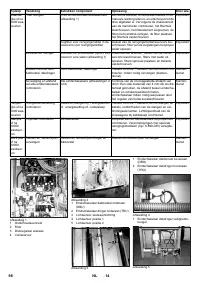

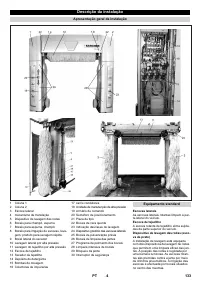

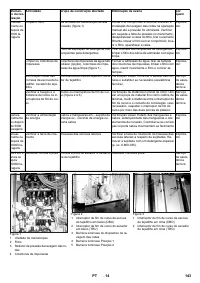

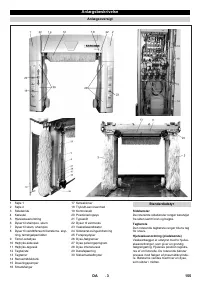

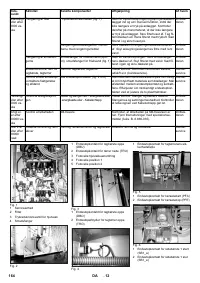

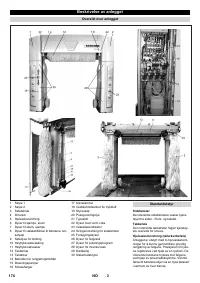

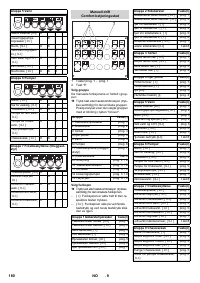

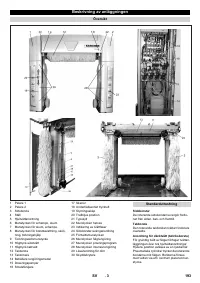

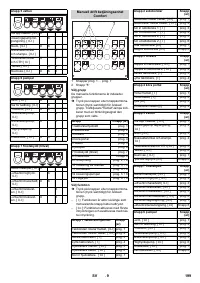

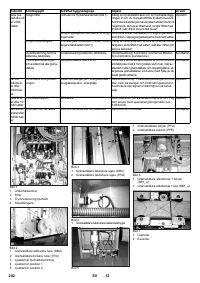

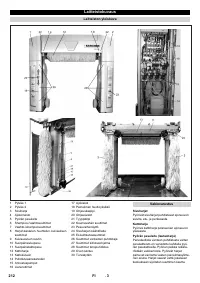

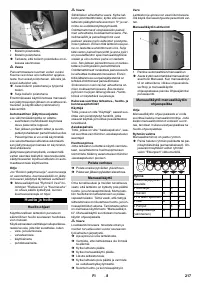

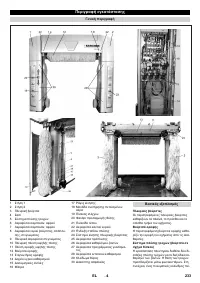

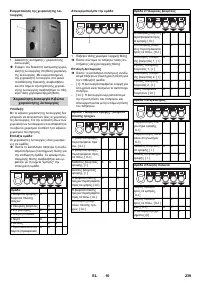

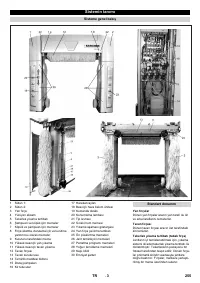

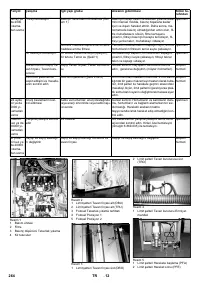

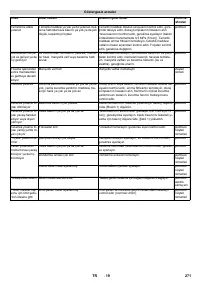

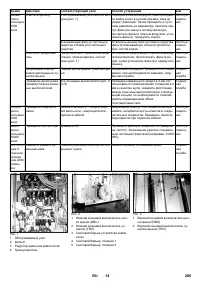

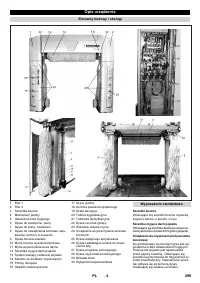

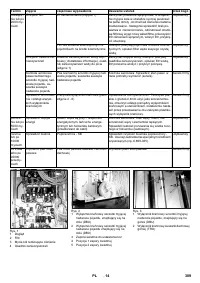

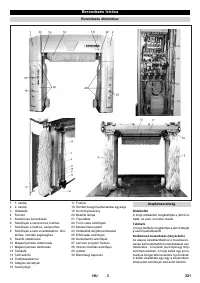

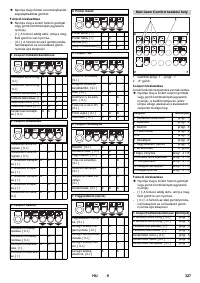

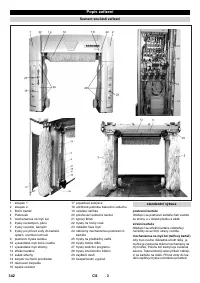

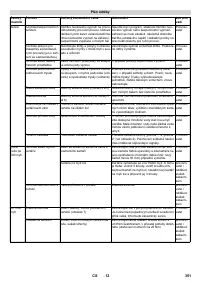

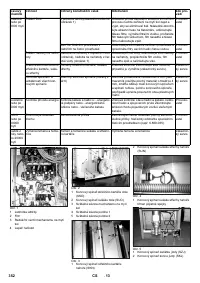

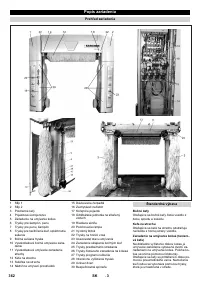

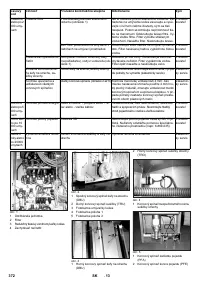

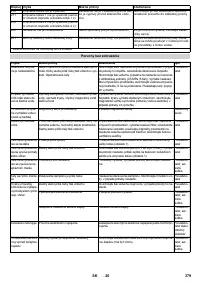

Figure 7

1 Running rollers

2 Eccentric

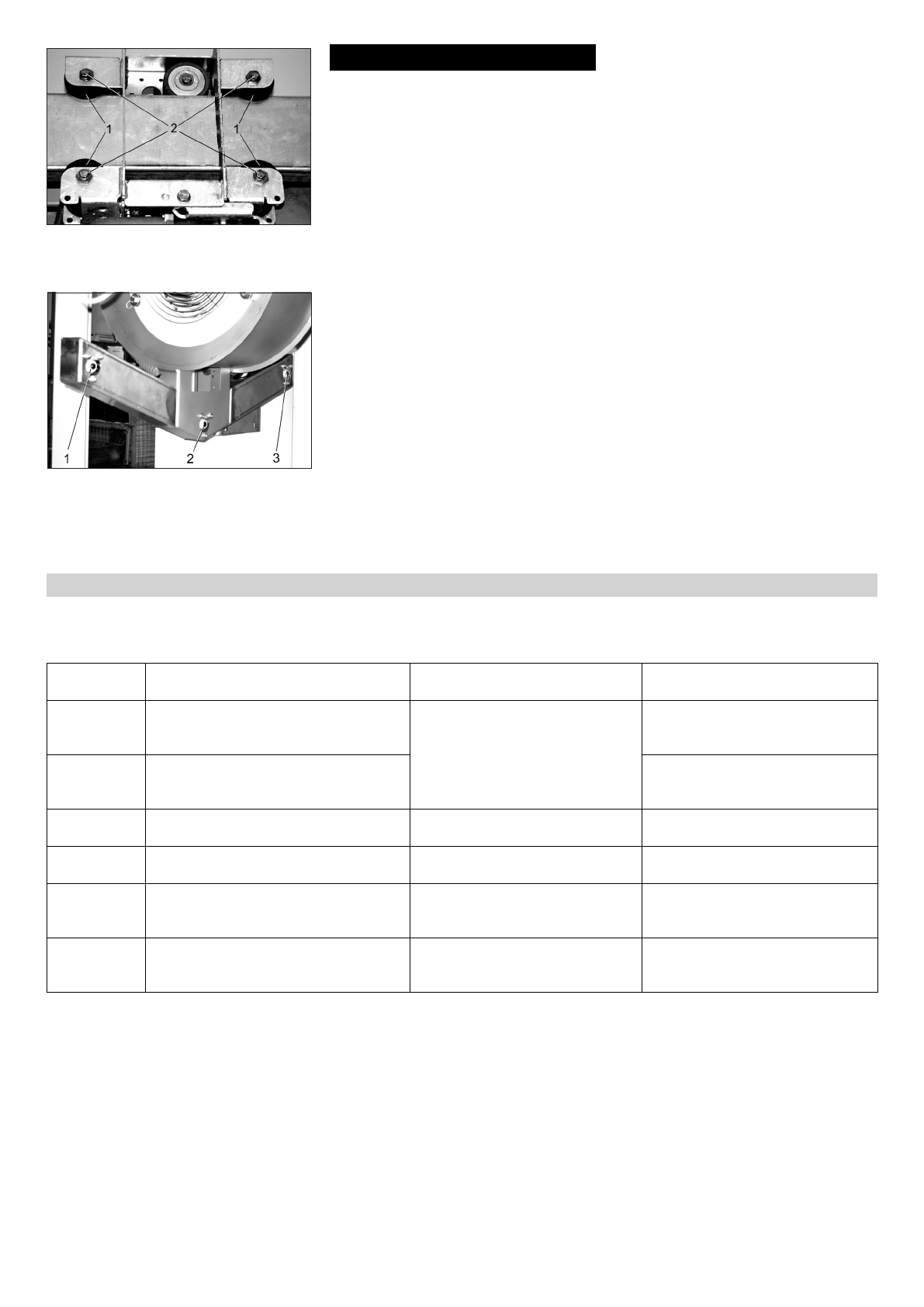

Figure 8

1 Light barrier of drier forward

2 Light barrier of drier in the middle

3 Light barrier of drier behind

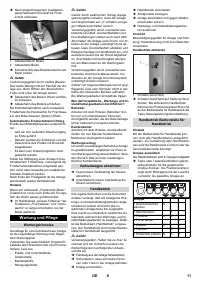

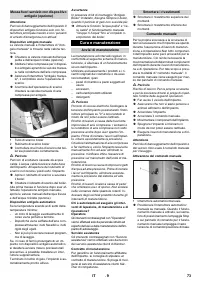

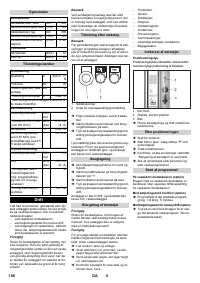

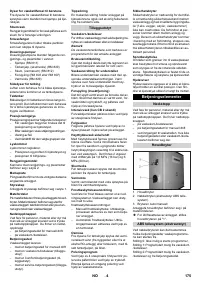

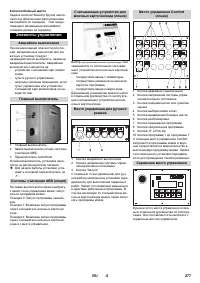

Danger

Risk of electric shock!

Work on electrical plant only to be carried

out by qualified electricians.

Switch the plant to voltage-free with all

work, in this case switch the plant at the

main switch to “0”and secure against it

switching on again.

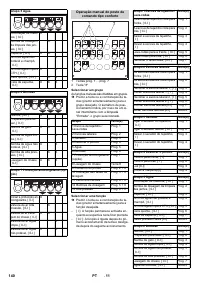

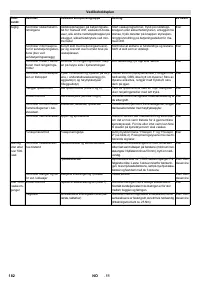

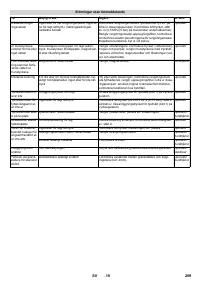

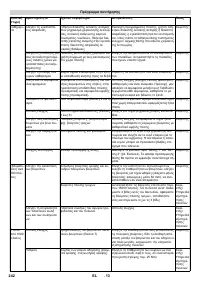

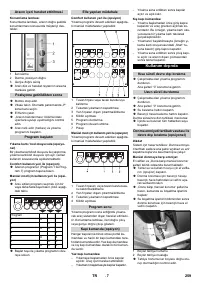

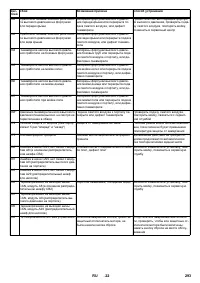

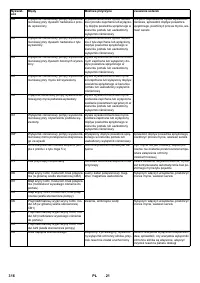

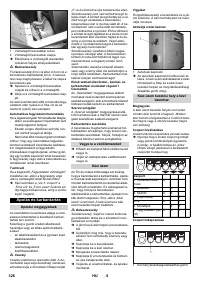

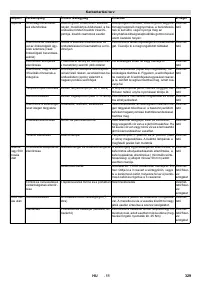

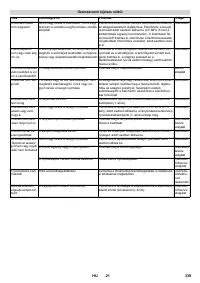

Who may remedy faults?

Operator

Work designated with the sign “Operator”

may only be carried out by persons who

have been instructed in the safe operation

and maintenance on the wash plant

Electricians

Persons with a professional training in the

electro-technical area.

Customer Service

Work designated with the sign “Customer

Service” may only be done by the fitters of

Kärcher Customer Service or fitters who

have been authorised by Kärcher.

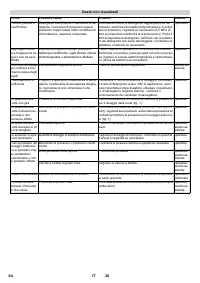

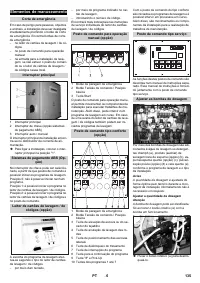

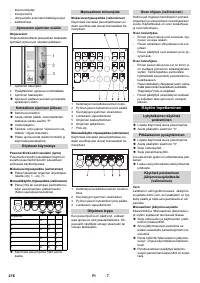

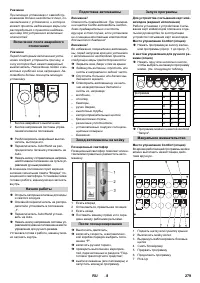

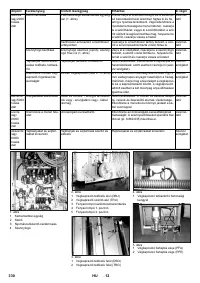

Danger

Risk of electric shock! Switch on the plant

voltage-free, in addition switch on the main

switch to “0” and secure against it switching

on again.

Risk of injury from compressed air unex-

pectedly emerging. . Compressed air con-

tainers also remain under pressure after

the plant has been switched off. It is abso-

lutely necessary to get rid of pressure be-

fore starting work on the plant. To do this,

turn off the compressed air supply and use

the manual operation to move the wheel

wash system in and out until the pressure

has been released. Then check for the ab-

sence of pressure on the manometer at the

maintenance unit.

Risk of injury from high-pressure water jet

unexpectedly emerging. The high pressure

system continues to remain under pressure

also after the plant has been switched off. It

is absolutely necessary to remove all pres-

sure in the high-pressure system before

starting work on the plant.

Risk of eye injuries from parts flying off or

dirt. Keep clear off rotating brushes. Gog-

gles must be worn during maintenance

work.

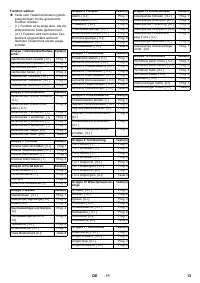

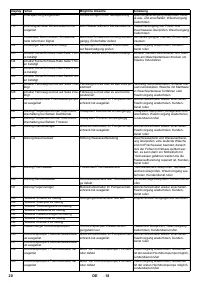

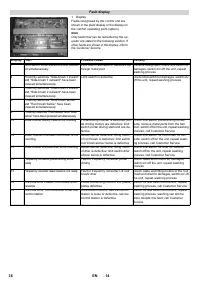

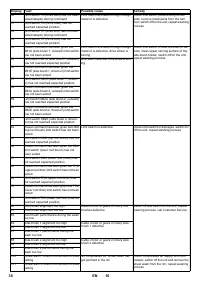

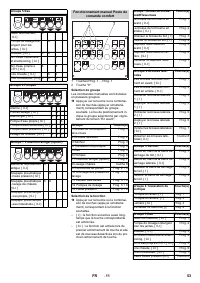

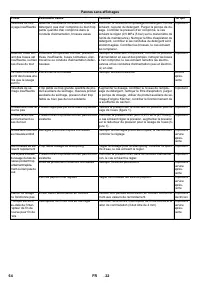

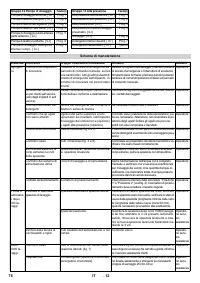

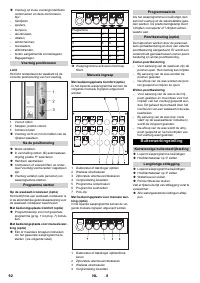

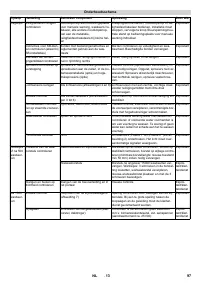

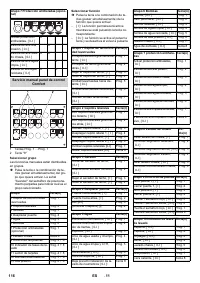

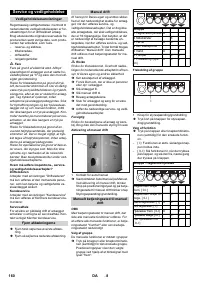

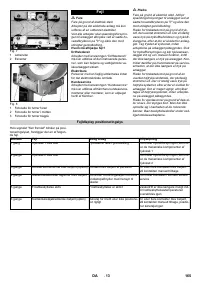

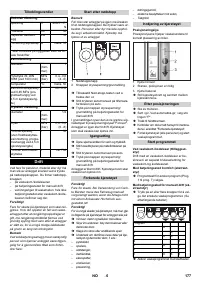

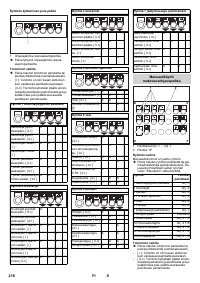

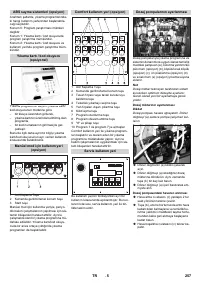

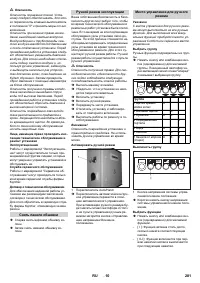

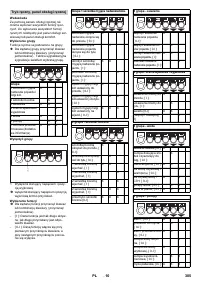

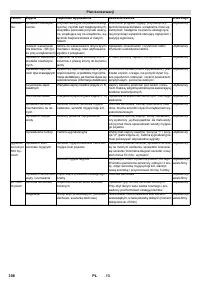

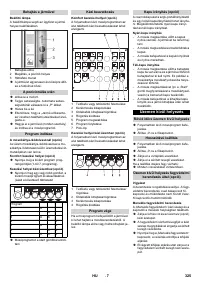

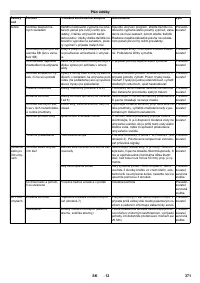

If the "drive forward" signal of the position-

ing ramp blinks, then one of the faults men-

tioned below has occurred.

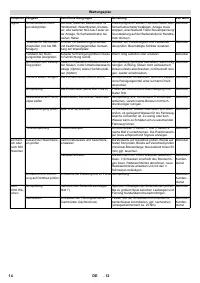

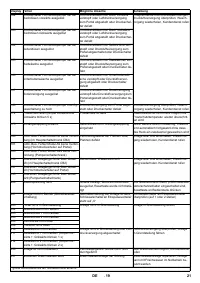

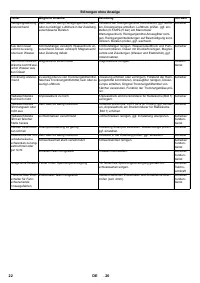

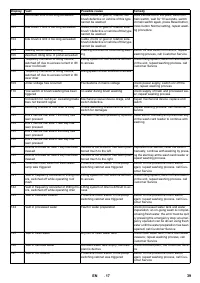

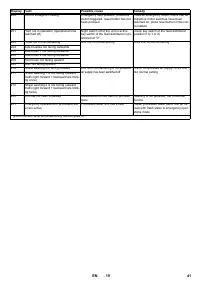

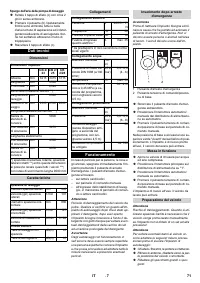

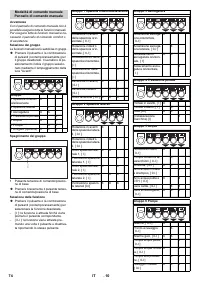

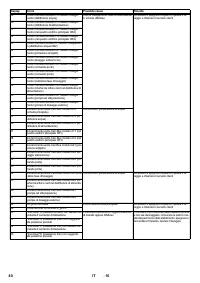

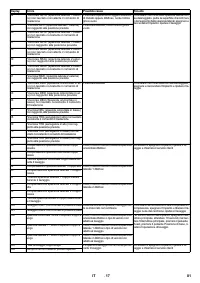

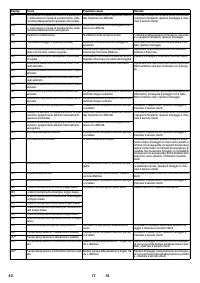

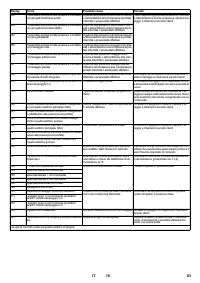

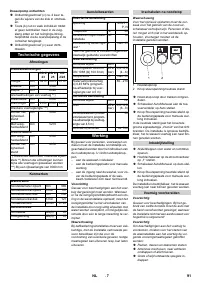

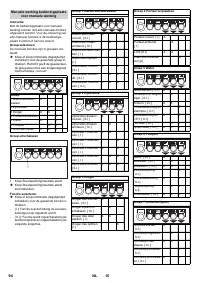

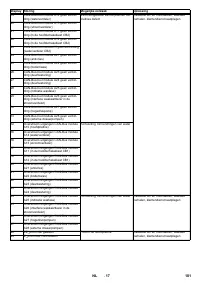

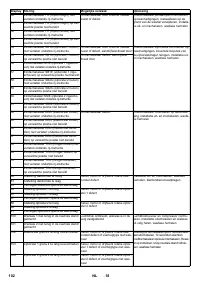

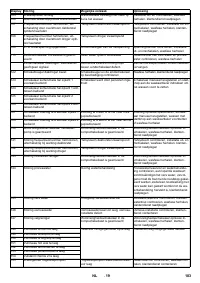

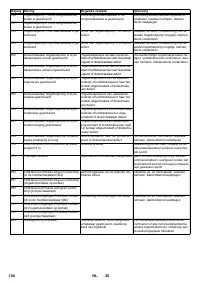

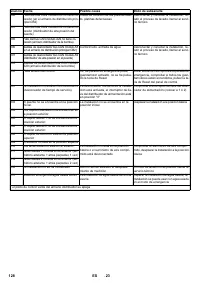

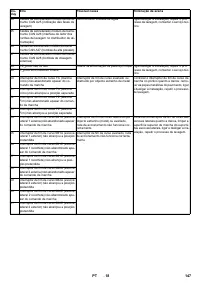

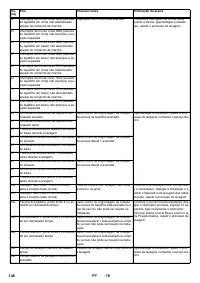

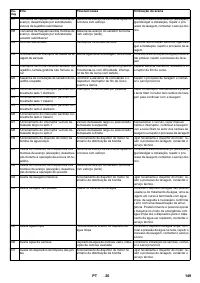

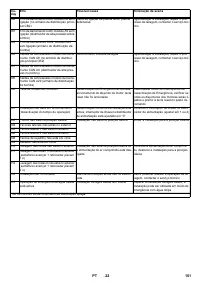

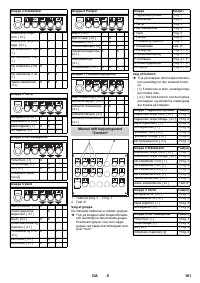

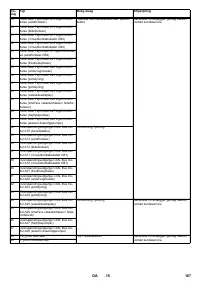

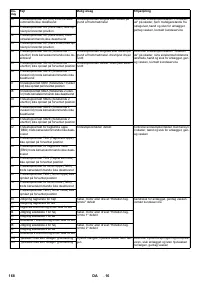

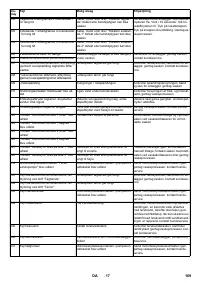

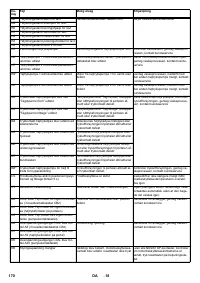

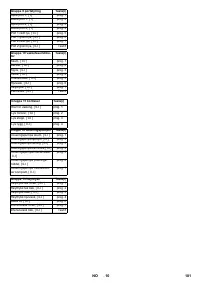

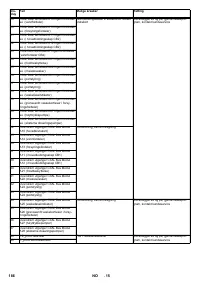

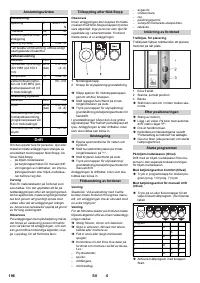

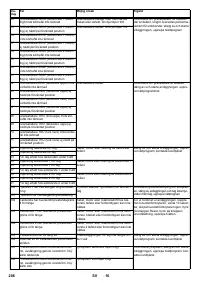

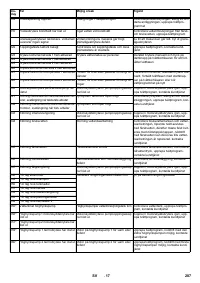

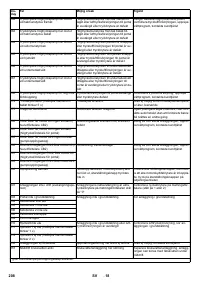

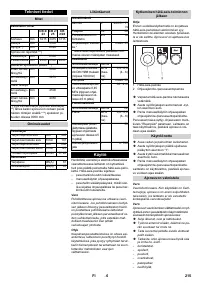

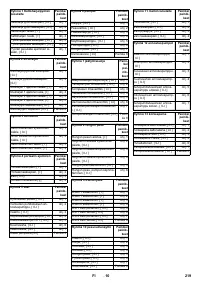

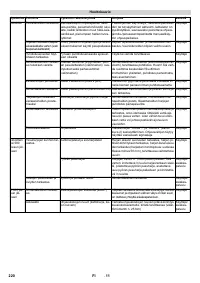

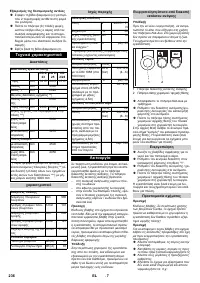

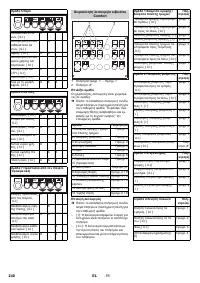

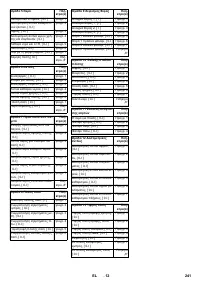

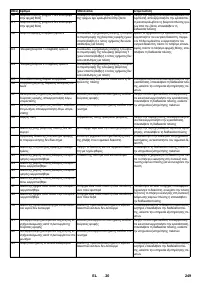

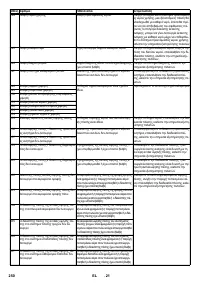

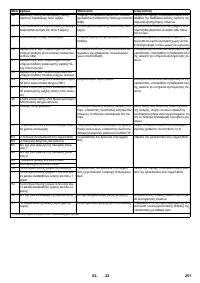

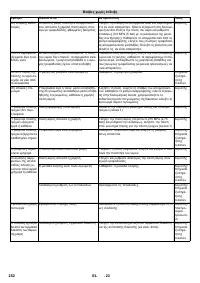

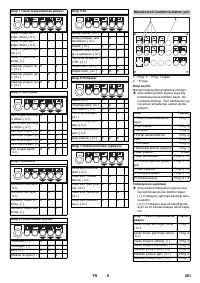

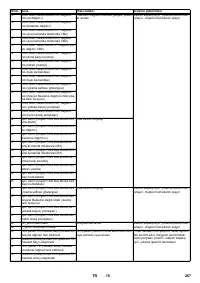

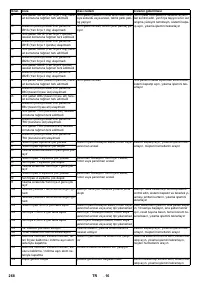

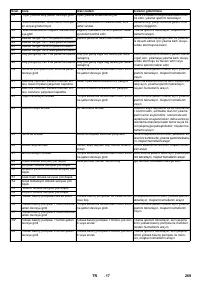

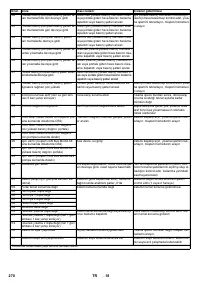

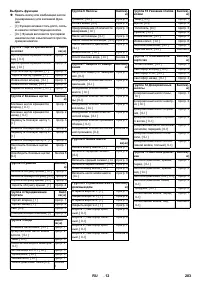

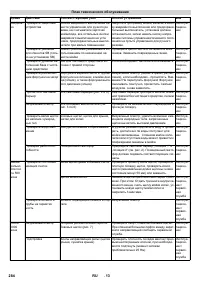

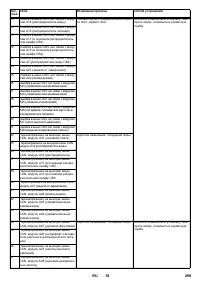

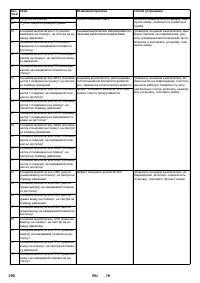

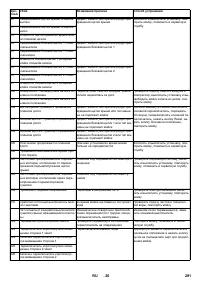

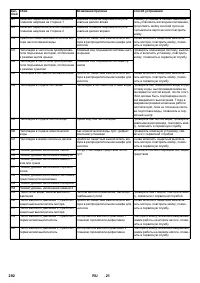

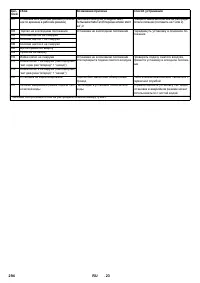

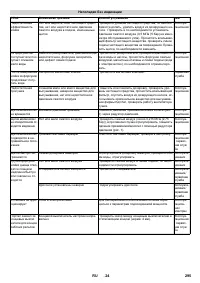

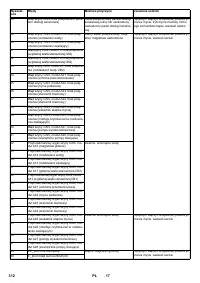

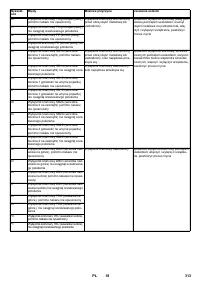

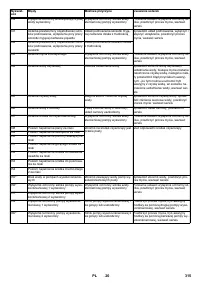

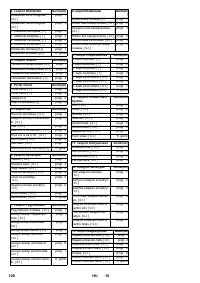

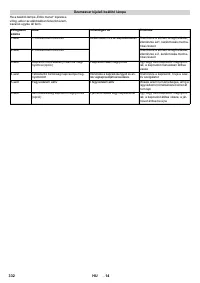

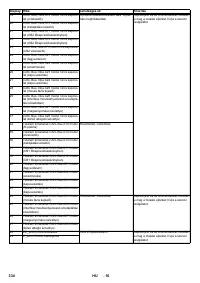

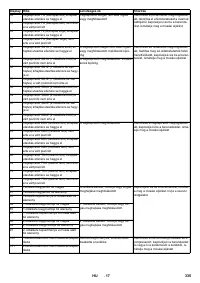

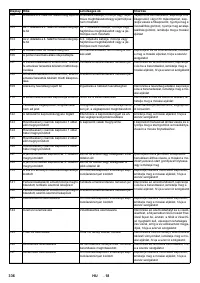

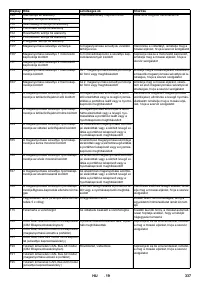

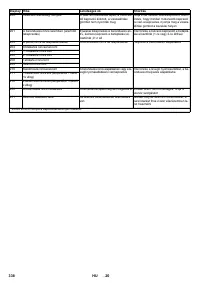

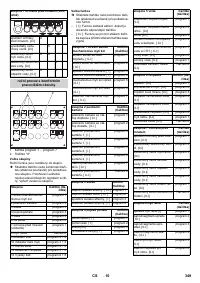

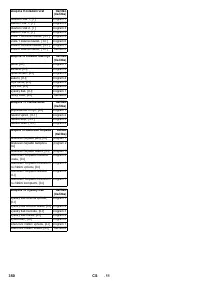

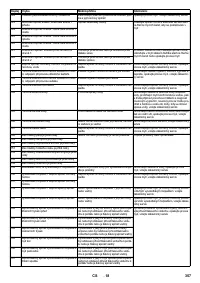

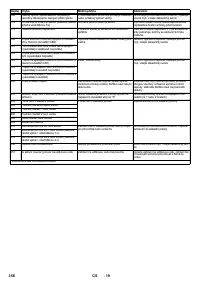

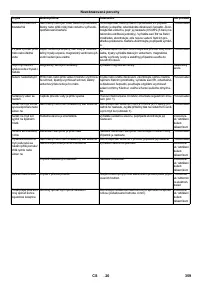

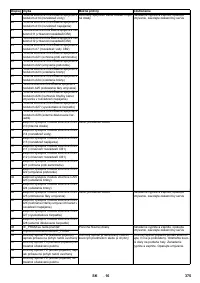

Faults

Fault display Positioning ramp

Number of

blinks

Fault

Possible cause

Remedy

once

Wheel washing 1 not facing outwards

Wheel washing is not in basic position Check compressed air supply, check

mechanical components of wheel

washing 1

twice

Wheel washing 2 not facing outwards

Check compressed air supply, check

mechanical components of wheel

washing 2

thrice

Short/ narrow hall switch pressed (Option) The switch has been pressed by a

person

One or more switches have been

pressed; reset switch manually

four times

Press safety switch roof drier

Check switching bracket and its limit

switch for damages

Check the switch, call Customer

Service

5 times

Frost protection is active

Frost proteciton is active

Washing cannot be done until the

anti-frost temperature is exceeded

again

6 times

Vehicle width switch has been pressed

(Option)

Vehicle is too broad or has been po-

sitioned wrongly

One or more switches have been

pressed; reset switch; re-position the

vehicle

35

EN