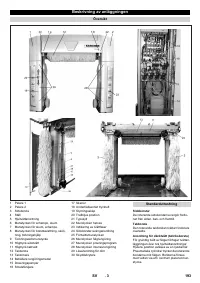

Мойки высокого давления Karcher CB 2 23 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

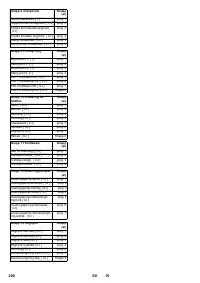

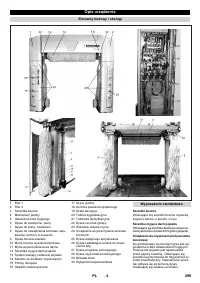

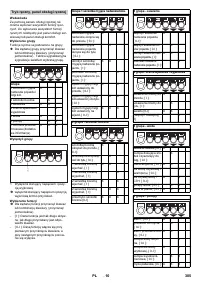

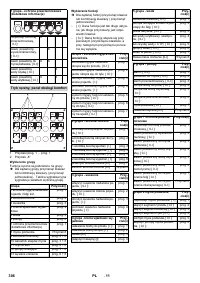

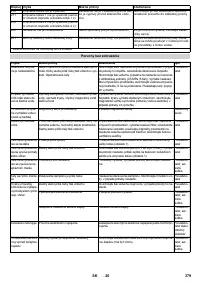

-

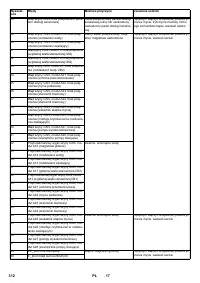

18

148

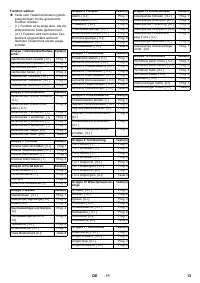

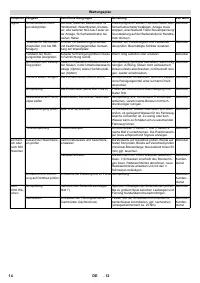

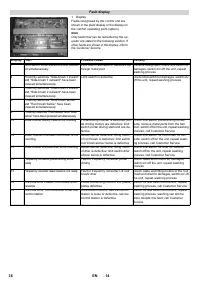

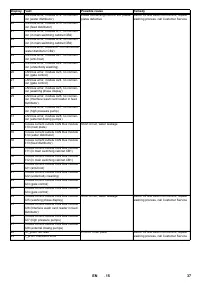

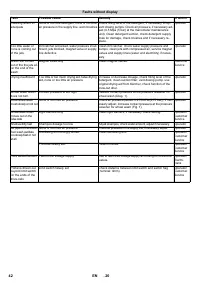

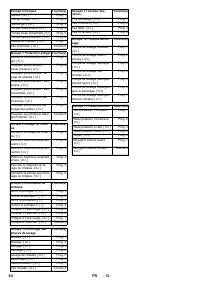

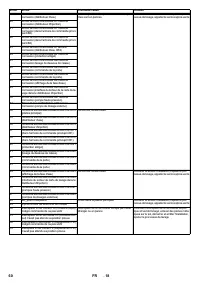

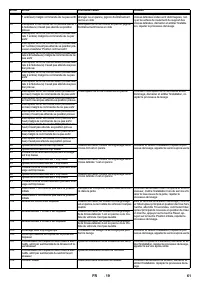

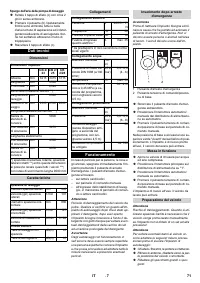

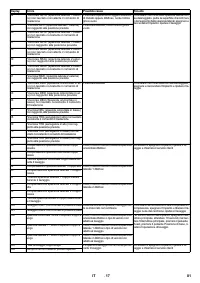

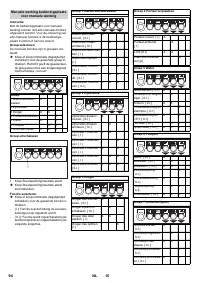

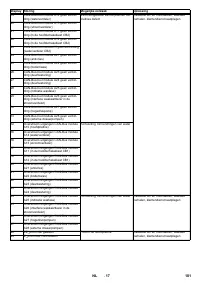

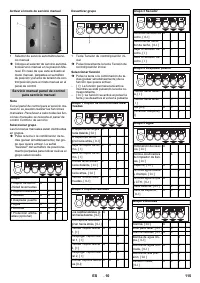

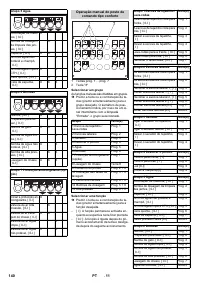

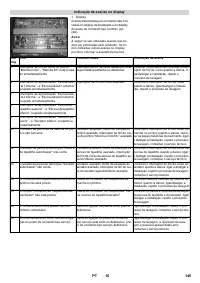

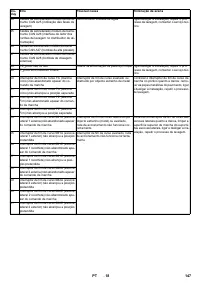

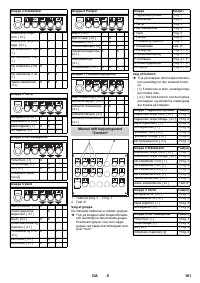

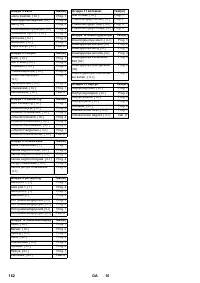

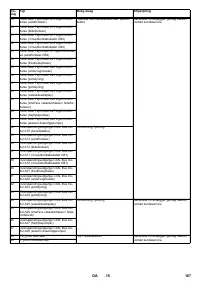

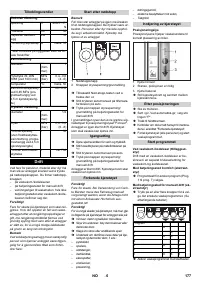

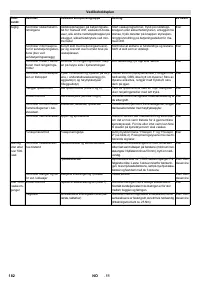

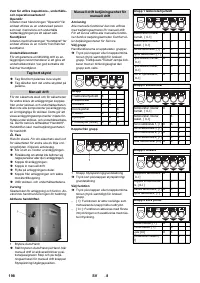

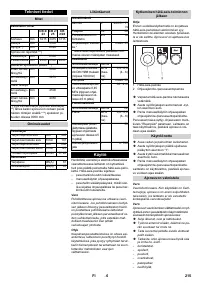

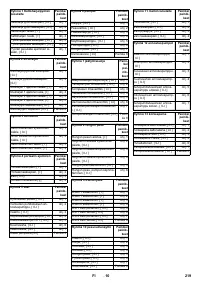

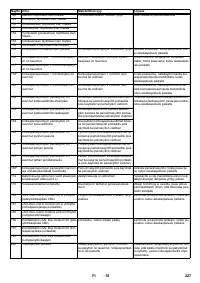

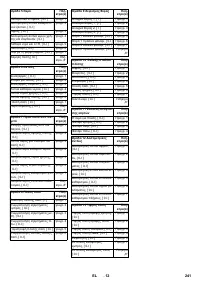

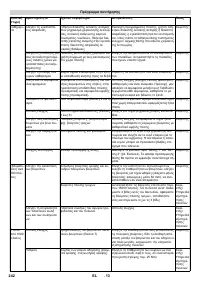

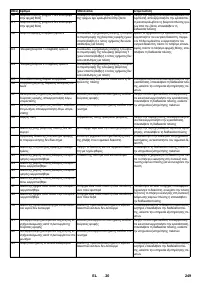

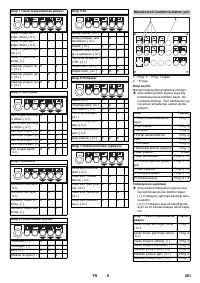

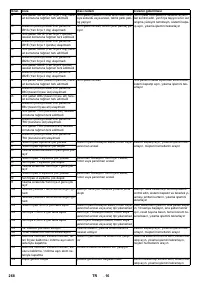

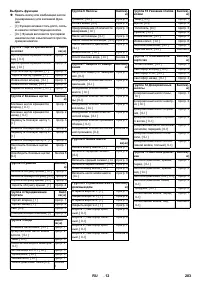

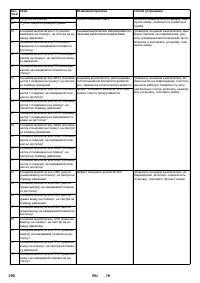

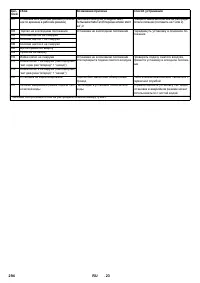

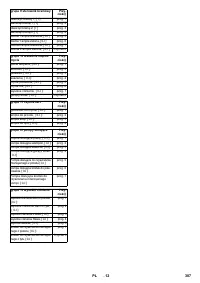

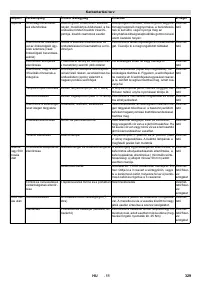

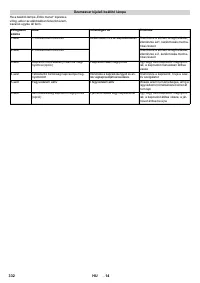

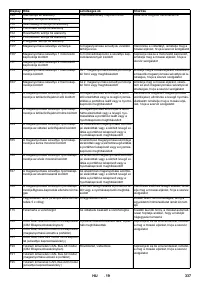

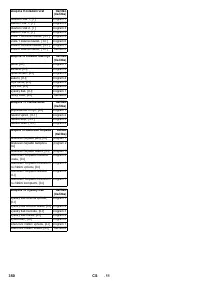

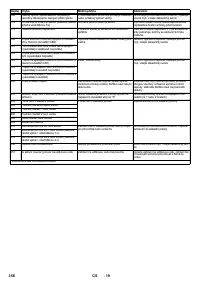

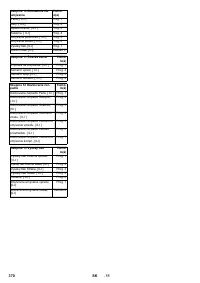

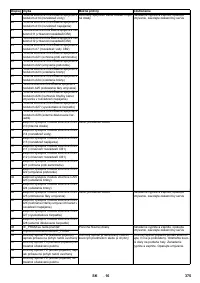

Filling level of foam too low

Detergent container almost empty

refill the corresponding detergent

149

Filling level of shampoo too low

150

Filling level of drying aid too low

151

Filling level of hot wax too low

152

Filling level of insect cleaner too low

153

Filling level of polish too low

154

Filling level of chemicals 2 too low

155*

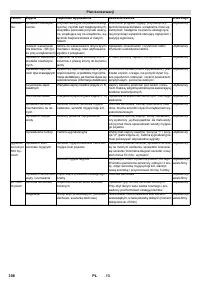

Lack of water supply to high pressure

pumps

Water supply tank for high pressure

pumps empty

Check water tank, repeat washing proc-

ess, call Customer Service

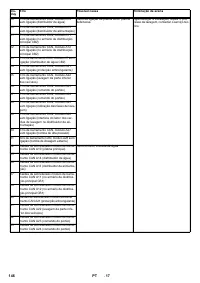

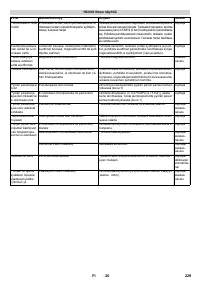

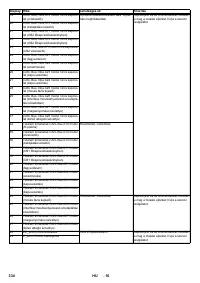

156*

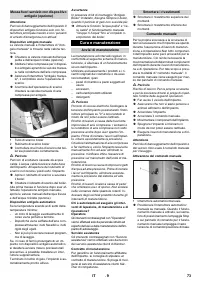

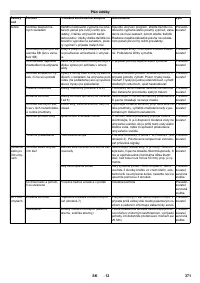

Protective motor switch high pressure

pump 1 was triggered

Protective motor switch in the pump

switching cabinet was triggered

Switch on the protective motor switch

again, repeat washing process, call Cus-

tomer Service

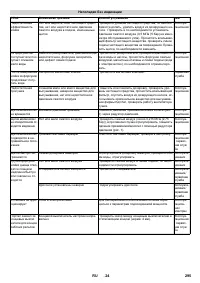

157*

Protective motor switch high pressure

pump 2 was triggered

159*

Thermal switch high pressure pump 1 was

triggered

Motor of high pressure pump 1 too hot

or defective

Repeat washing process, emergency op-

eration possible by using the second high

pressure pump, call Customer Service

160*

Thermal switch high pressure pump 2 was

triggered

Motor of high pressure pump 2 is too

hot or defective

Repeat washing process, emergency op-

eration with first high pressure pump is

possible, call Customer Service

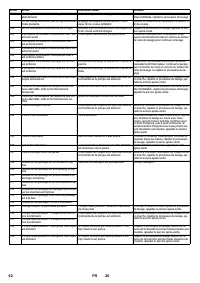

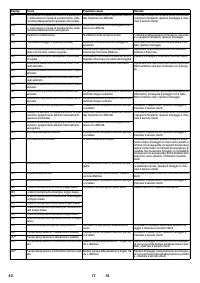

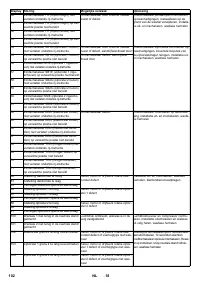

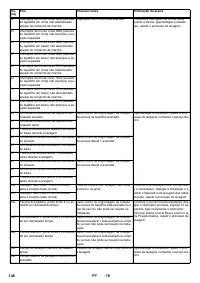

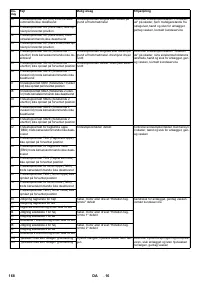

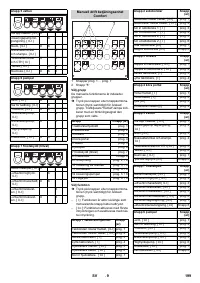

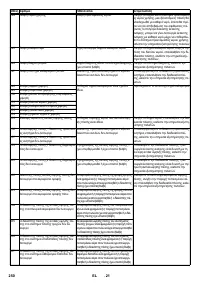

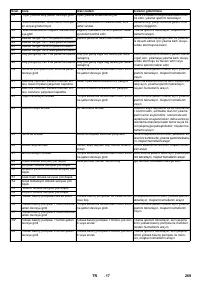

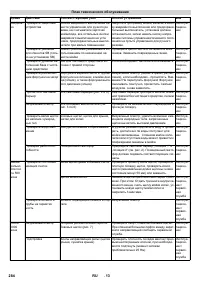

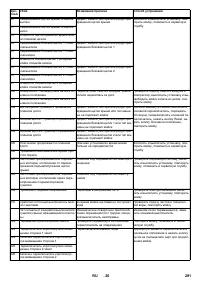

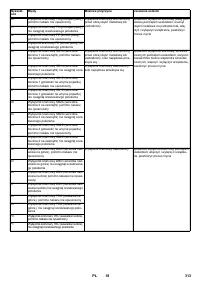

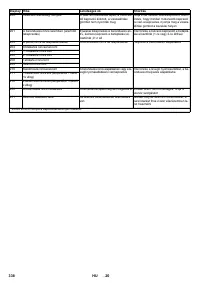

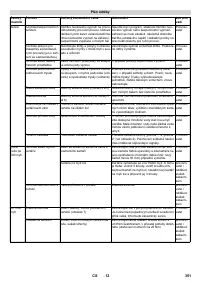

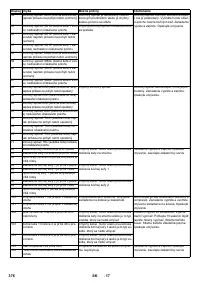

162

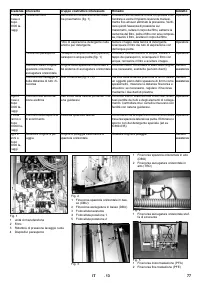

Pressure switch of high pressure pump

was triggered forward for roof nozzles

High pressure nozzles of roof blocked

towards the front or compressed air

supply to the portal has stopped or

pressure switch is defective

Clean the corresponding high pressure

nozzles, check compressed air supply, re-

peat washing process, call Customer

Service

163

Pressure switch of high pressure pump

was triggered backward for roof nozzles

High pressure nozzles of roof blocked

towards the rear or compressed air

supply to the portal has stopped or

pressure switch is defective

164

Pressure switch of high pressure pump

was triggered for side nozzles

High pressure nozzles of side pipes

blokked or compressed air supply to

portal has been switched off or pres-

sure switch is defective

165

Pressure switch of high pressure pump

was triggered for wheel cleaning

High pressure nozzles of wheel wash-

ing blocked or compressed air supply

to portal has been switched off or pres-

sure switch is defective

166

Pressure switch of high pressure pump

was triggered for underbody cleaning

High pressure nozzles of underbody

cleaning blocked or compressed air

supply to portal has been switched off

or pressure switch is defective

167

Pressure switch of high pressure pump

was triggered for floor cleaning

High pressure nozzles of floor clean-

ing blocked or compressed air supply

to portal has been switched off or pres-

sure switch is defective

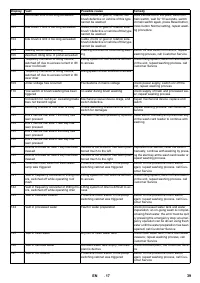

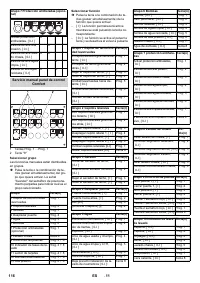

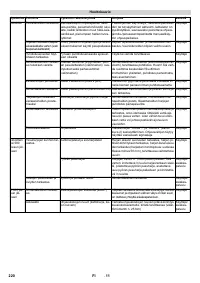

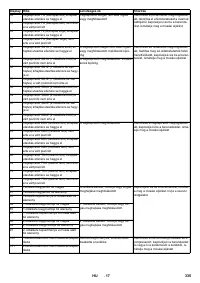

168*

Pressure switch of high pressure pump

too high despite bypass switching

Compressed air supply to the portal

has been stopped or pressure switch

is defective

Check compressed air supply, repeat

washing process, call Customer Service

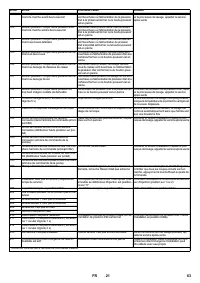

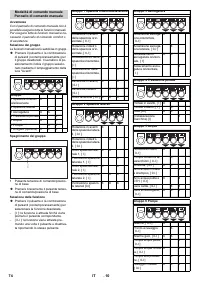

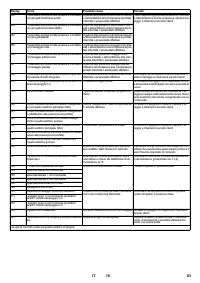

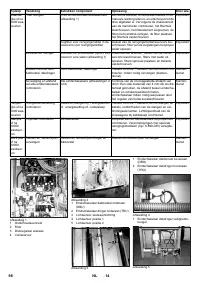

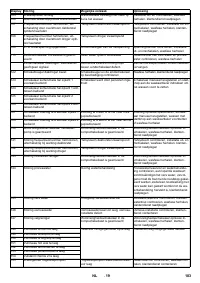

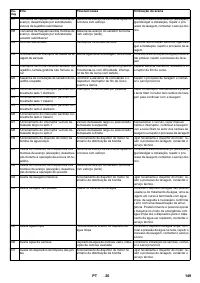

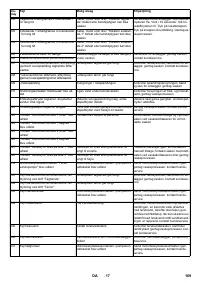

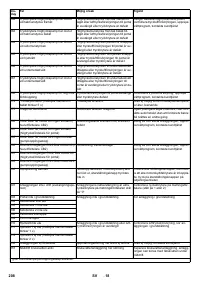

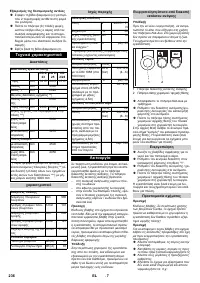

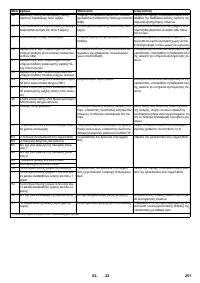

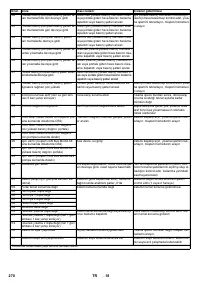

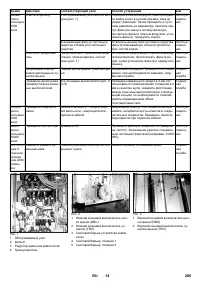

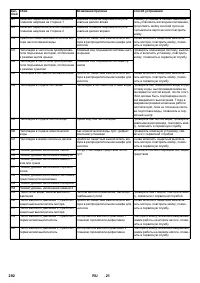

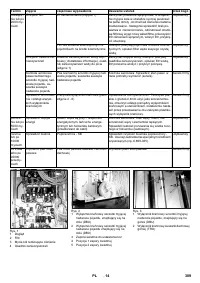

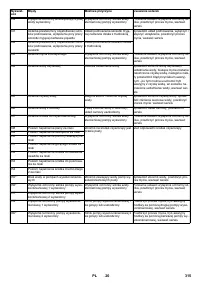

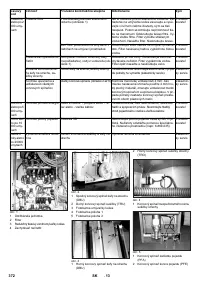

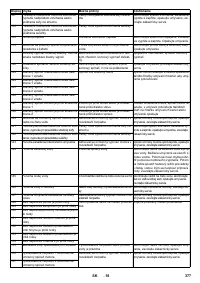

172

Anti-frost active (traffic signal forward and

backward blinks five times)

Frost proteciton is active

Washing cannot be done until the anti-

frost temperature is exceeded again

175

Trailer coupling detected

Side brush has got hooked into the

trailer coupling

No action is required; washing will contin-

ue automatically without the back being

washed a second time

180

CAN bus error, module A8, no connection

(in main switching cabinet CB2)

Loose connecting chord of the plates,

plates defective

Switch off and switch on the unit, repeat

washing process, call Customer Service

181

CAN bus error, module A9, no connection

(high pressure distributor to portal)

185

CAN bus error, module A29, no connec-

tion (pump switching cabinet)

190

Excess current outlets CAN Bus module

A8 (in main switching cabinet CB2)

Short circuit, water leakage

Switch off and switch on the unit, repeat

washing process, call Customer Service

191

Excess current outlets CAN Bus module

A9 (high pressure distributor to portal)

195

Excess current outlets CAN Bus module

A29 (pump switching cabinet)

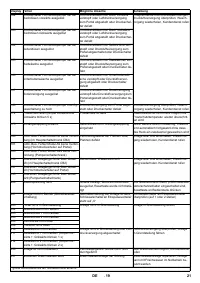

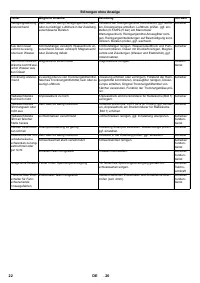

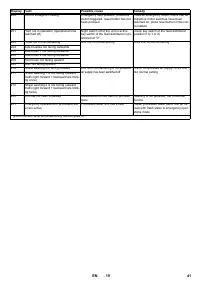

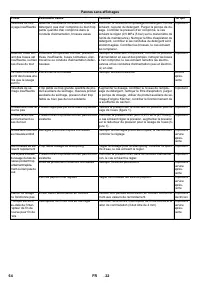

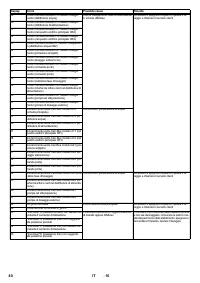

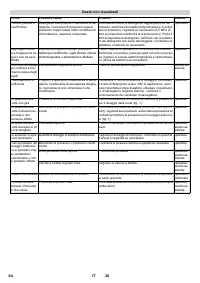

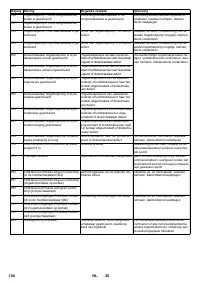

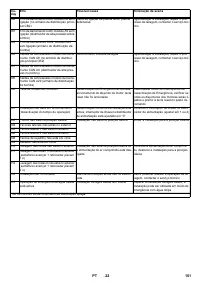

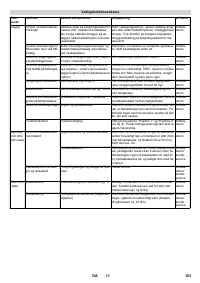

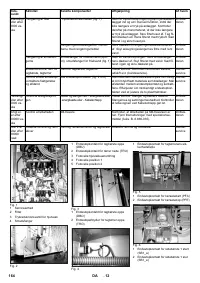

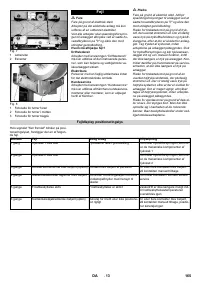

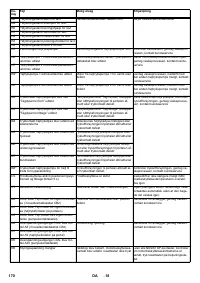

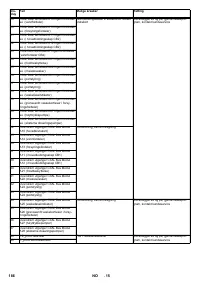

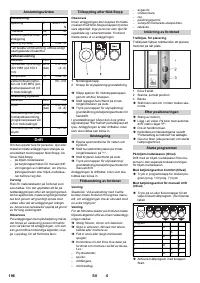

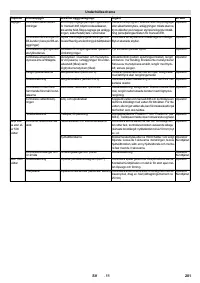

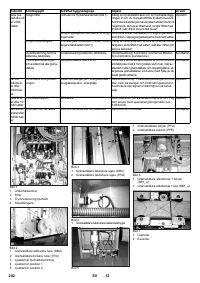

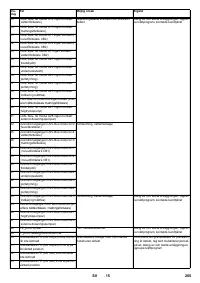

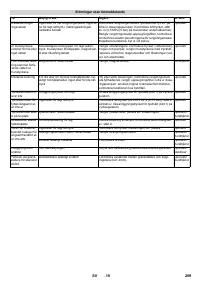

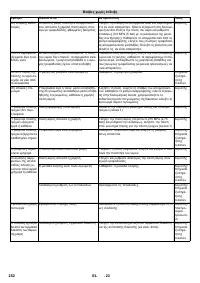

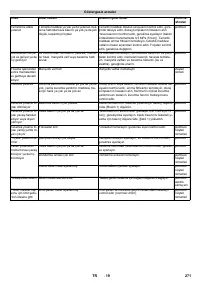

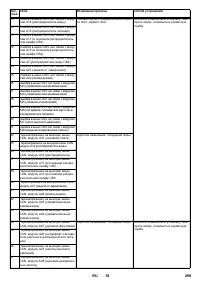

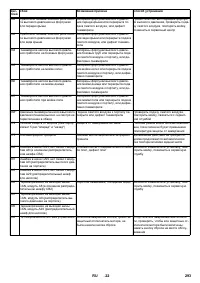

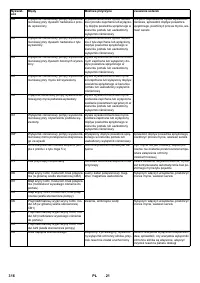

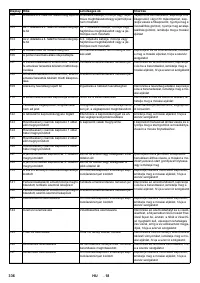

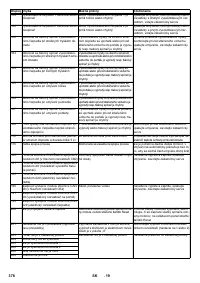

Display Fault

Possible cause

Remedy

40

EN