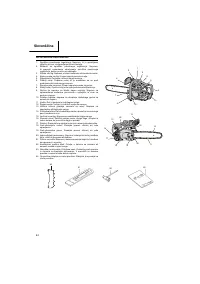

Бензопилы Hitachi CS33EDT - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

14

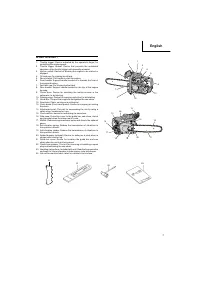

English

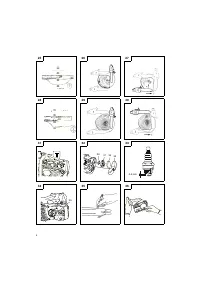

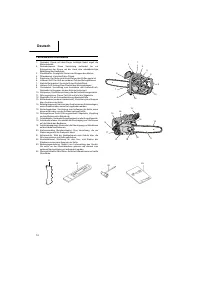

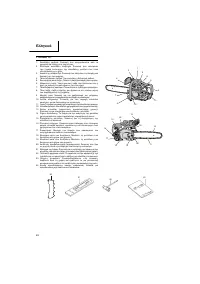

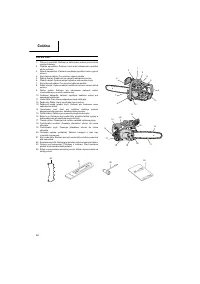

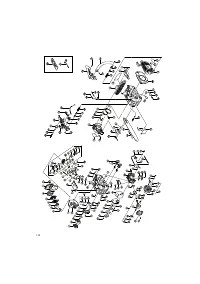

41. Top plate

42. Working corner

43. Side plate

44. Gullet

45. Heel

46. Chassis

47. Rivet hole

48. Toe

49. Depth gauge

50. Correct angle on top plate (degree of angle depends on chain

type)

51. Slightly protruding “hook ” or point (cur ve on non-chisel chain)

52. Top of depth gauge at correct height below top plate

53. Front of depth gauge rounded o

ff

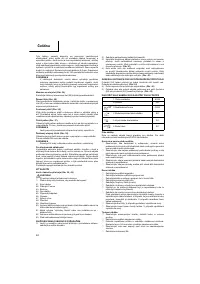

LOWERING

DEPTH

GAUGES

WITH

A

FILE

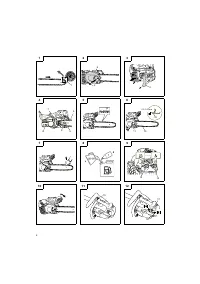

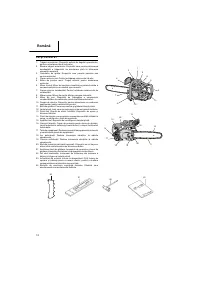

1) If you sharpen your cutters with a

fi

le holder, check and lower the

depth.

2) Check depth gauges ever y third sharpening.

3) Place depth gauge tool on cutter. If depth gauge projects,

fi

le

it level with the top of the tool. Always

fi

le from the inside of the

chain toward an outside cutter. (

Fig.

41

)

4) Round

o

ff

front corner to maintain original shape of depth gauge

after using depth gauge tool. Always follow the recommended

depth gauge setting found in the maintenance or operator

manual for your saw. (

Fig.

42

)

GENERAL

INSTRUCTIONS

FOR

FILING

CUT TERS

File (54) cutter on one side of the chain from the inside out. File on

for ward stroke only. (

Fig.

43

)

5) Keep all cutters the same length. (

Fig.

44

)

6) File enough to remove any damage to cutting edges (side plate

(55) and top plate (56)) of cutter. (

Fig.

45

)

SHARPENING

ANGLES

FOR

SHARPENING

SAW

CHAIN

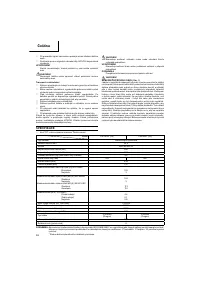

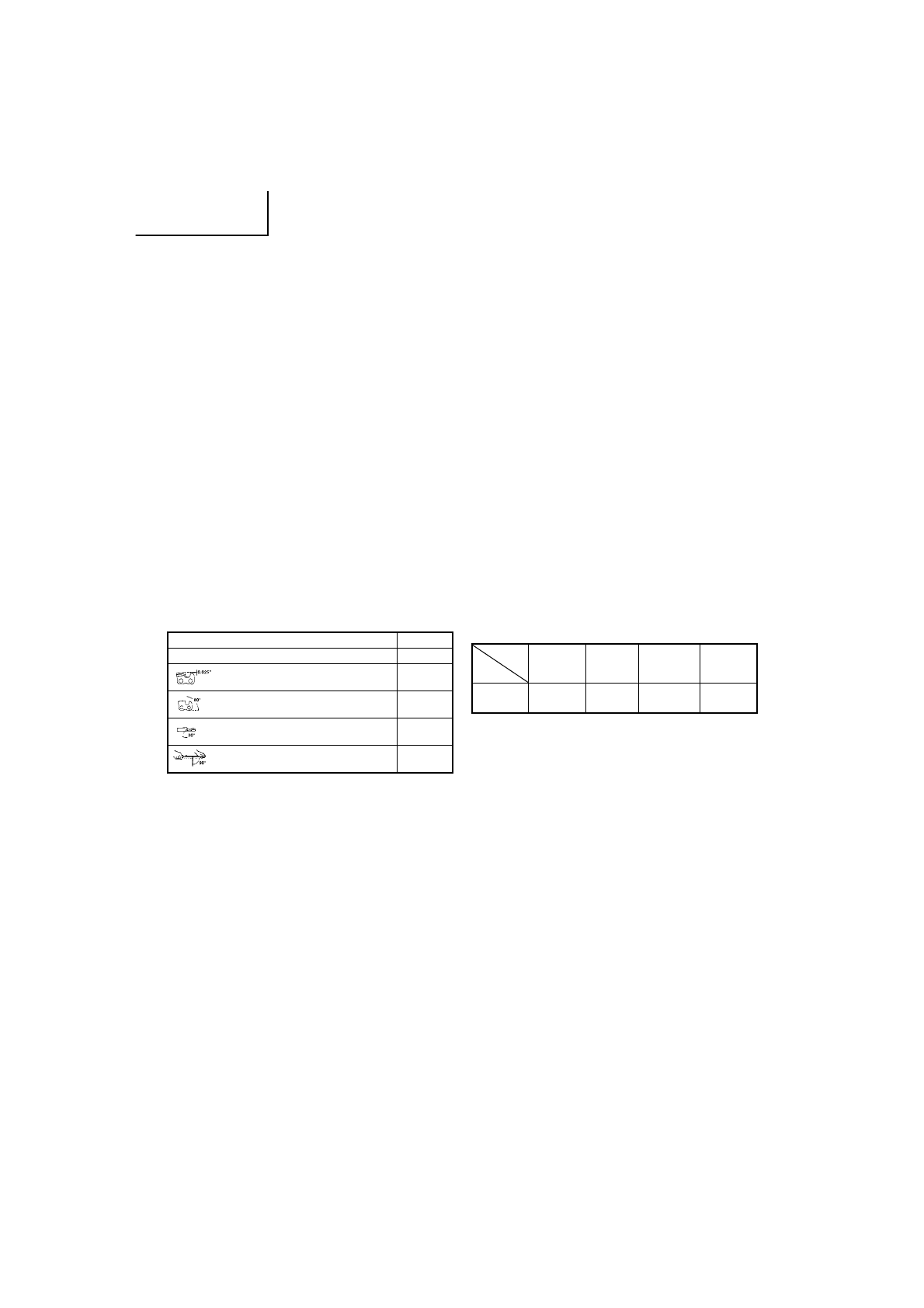

1. Par t Number

91VG

2. Pitch

3/8”

3. Depth Gauge Setting

0.025"

4. Side Plate Filing Angle

80°

5. Top Plate Angle

30°

6. File Guide Angle

90°

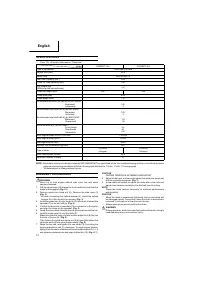

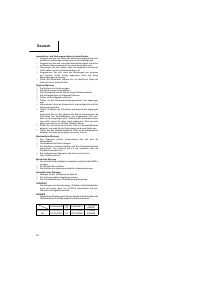

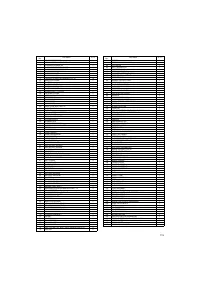

Maintenance

schedule

Below you will

fi

nd some general maintenance instructions. For

fur ther information please contact HITACHI dealer.

Inspection

and

service

before

use

○

Check that no peel-o

ff

, degradation, or damage is obser ved in

the Anti-vibration rubber members, and no loosening or damage

is obser ved in their

fi

xtures.

○

Check that no damage is obser ved in the Anti-vibration springs,

and no loosening or damage is obser ved in their

fi

xtures.

○

Check that no deformation or damage is obser ved in the front

and rear handles.

○

Check that the

fi

xtures for front and rear handles are su

ffi

ciently

tightened and free of damage.

○

Check that bolts, nuts, etc. used for each par t are su

ffi

ciently

tightened and free of damage.

Daily

maintenance

○

Clean the exterior of the unit.

○

Clean the chain oil

fi

lter por t.

○

Clean the groove and oil

fi

lter por t in the guide bar.

○

Clean the side case of saw dust.

○

Check that the saw chain is sharp.

○

Check that the bar nuts are su

ffi

ciently tightened.

○

Make sure that the chain transpor t guard is undamaged and that

it can be securely

fi

tted.

○

Check that nuts and screws are su

ffi

ciently tightened.

Especially inspect the bolt of mu

ffl

er and ensure that they are

properly tightened before star ting engine. Should any of the

bolts be loose, retighten them immediately. Failure to do so

could result in serious hazard.

○

Check the tip of the bar. Please exchange it for the new one

when it is worn out.

○

Check the band of chain brake. Please exchange it for the new

one when it is worn out.

Weekly

maintenance

○

Check the recoil star ter, especially cord and return spring.

○

Clean the exterior of the spark plug.

○

Remove the spark plug and check the electrode gap. Adjust it to

0.6 mm or change the spark plug.

○

Check that the air intake at the recoil star ter is not clogged.

○

Clean the air

fi

lter.

Monthly

maintenance

○

Rinse the fuel tank with gasoline, and clean fuel

fi

lter.

○

Clean chain oil

fi

lter.

○

Clean the exterior of the carburetor and the space around it.

Quarterly

maintenance

○

Clean the cooling

fi

ns on the cylinder.

○

Clean the fan and the space around it.

○

Clean the mu

ffl

er of carbon.

CAUTION

Cleaning of cylinder

fi

ns, fan and mu

ffl

er shall be done by a

HITACHI Authorized Ser vice Center.

NOTE

When ordering the par ts to your nearest dealer, please use the

item numbers showing on the par ts breakdown section in this

instruction.

BAR NO.

LENGTH-

T YPE

NOSE-

T YPE

CHAIN

NO.

(OREGON)

MODEL NO.

E&S

PO12-50CR

PO14-50CR

12

″

14

″

SPROCKET

SPROCKET

91VG045

91VG052

000Book̲CS33EDT̲EE.indb 14

000Book̲CS33EDT̲EE.indb 14

2011/08/06 8:57:20

2011/08/06 8:57:20