Электропилы Bosch PTS 10 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

English |

33

Bosch Power Tools

1 609 92A 039 | (28.9.12)

Use only saw blades that correspond with the characteristic

data given in these operation instructions and that are tested

and marked in accordance with EN 847-1.

Use only saw blades recommended by the tool manufacturer,

and suitable for sawing the materials to be cut.

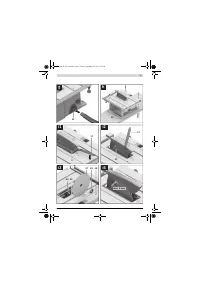

Removing the Saw Blade

– Using the ring spanner

17

, lift up the insert plate

3

at the

front and remove it from the notches

36

.

– Turn crank

12

clockwise to the stop, so that the saw blade

37

is in the highest possible position above the saw table.

– Turn the clamping nut

48

with the ring spanner

17

(23 mm) and at the same time, pull the spindle lock lever

47

until it engages.

– Keep the spindle lock lever pulled and unscrew the clamp-

ing nut turning in anticlockwise direction.

– Remove the clamping flange

49

.

– Remove the saw blade

37

.

Mounting the Saw Blade

If required, clean all parts to be mounted prior to assembly.

– Place the new saw blade onto the supporting flange

50

of

the tool spindle

51

.

Note:

Do not use saw blades that are too small. The clearance

between saw blade and riving knife must not exceed 5 mm

(max.).

When mounting the saw blade, pay attention that the

cutting direction of the teeth (arrow direction on the

saw blade) corresponds with the direction of the arrow

on the blade guard!

– Mount the clamping flange

49

and the clamping nut

48

.

– Turn the clamping nut

48

with the ring spanner

17

(23 mm) and at the same time, pull the spindle lock lever

47

until it engages.

– Tighten the clamping nut in clockwise direction.

– Reinsert the insert plate

3

. (see figure c3)

Operation

Before any work on the machine itself, pull the mains

plug.

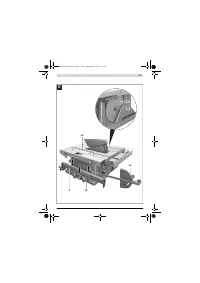

Transport and Working Position of the Saw Blade

Transport Position

– Turn crank

12

in anticlockwise direction until the teeth of

the saw blade

37

are positioned below the saw table

11

.

Working Position

– Turn the crank

12

clockwise, until the teeth of the saw

blade

37

are positioned above the workpiece.

Note:

Take care that the blade guard is properly positioned.

When sawing, it must always face against the workpiece.

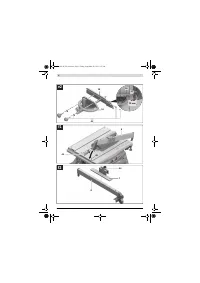

Increasing the Size of the Saw Table

Long workpieces must be underlaid or supported at their free

end.

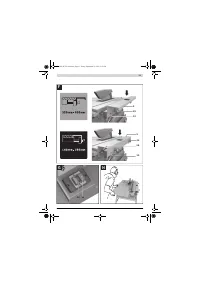

Table Extension/Table Width Enlargement (see figure A)

To increase the saw table surface, the following rails can be

pulled out at the rear as well as on the right-hand side of the

power tool:

Table extension 2

(extends the saw table

11

toward the rear

by 215 mm)

and/or

Table width enlargement 10

(enlarges the saw table

11

to-

ward the right by 285 mm)

– Grasp the requested rail centrally and from below, and pull

it out maximally to the stop.

– To lock in position, tighten the corresponding fastening

knobs (

23

or

26

) against the guide rods.

For heavy workpieces, it may be required to support the rails.

Sliding Table (see figure B)

With the sliding table

1

, workpieces to a maximum width of

350 mm can be sawn.

At the same time, a higher precision is achieved during saw-

ing, especially in conjunction with the angle stop

16

. (see

“Sawing Mitre Angles with the Sliding Table”, page 35)

– For this, tilt the locking lever

24

toward the right.

In this manner, the sliding table can be moved both toward

the front as well as toward the rear to the stop.

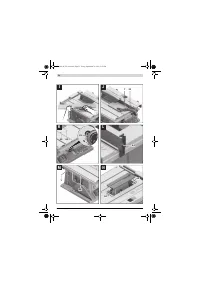

Adjusting the Cutting Angle

To ensure precise cuts, the basic adjustment of the machine

must be checked and adjusted as necessary after intensive

use (see “Checking and Adjusting the Basic Adjustment”,

page 35).

Adjusting Mitre Angles (Angle Stop) (see figure C)

The mitre angle can be set in the range from 60 ° (left side) to

60 ° (right side).

– Loosen the locking knob

52

in case it is tightened.

– Turn the angle stop until the angle indicator

53

indicates

the requested mitre angle.

– Tighten the locking knob

52

again.

Adjusting Bevel Angles (Saw Blade) (see figure D)

The bevel angle can be set in the range from 0 ° to 45 ° .

– Lightly unscrew the locking knob

29

in anticlockwise direc-

tion.

Note:

By completely loosening the locking knob, the saw

blade tilts approx. to the 30 ° position by means of gravity

force.

– Press handwheel

54

toward the rear and hold it in this po-

sition.

This forces the teeth on the connecting link to engage in

the gear ring of the handwheel.

– Turn the handwheel until the angle indicator

55

indicates

the requested bevel angle on the scale

56

.

– Tighten the locking knob

29

again.

For quick and precise setting of the standard angles 0 °

and 45 °

, end stops are given at the housing.

OBJ_BUCH-783-006.book Page 33 Friday, September 28, 2012 2:27 PM

Содержание

- 202 Применение электроинструмента и обращение с ним

- 203 Символы; Символы и их значение

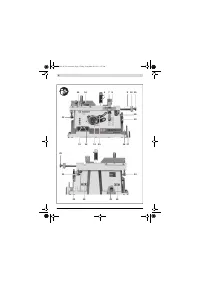

- 204 Описание продукта и услуг; Применение по назначению

- 205 Технические данные; Применяйте средства защиты органов слуха!; Заявление о соответствии; Сборка; Комплект поставки; В исполнениях электроинструмента с подставкой; Размеры пильных дисков

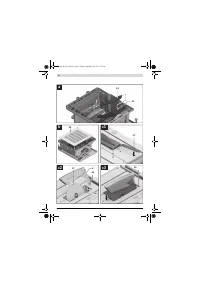

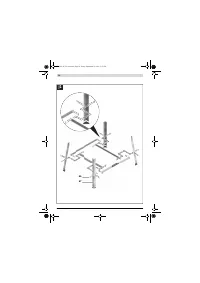

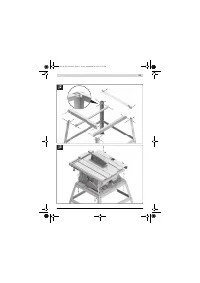

- 206 Первое включение; Последовательность монтажа; Монтаж снизу

- 207 Отсос пыли и стружки; Избегайте скопления пыли на рабочем месте.; Стационарный или временный монтаж

- 208 Работа с инструментом; Увеличение площади стола

- 209 Настройка параллельных упоров

- 210 Максимальные размеры заготовки; Пиление; Выполнение прямых пропилов; Основные настройки – контроль и коррекция; Настройка угла наклона в 0 °

- 211 Хранение электроинструмента; Техобслуживание и сервис; Техобслуживание и очистка; Очистка; Принадлежности; Товарный No

- 212 Россия; Утилизация