Сварочное оборудование Telwin TECHNOLOGY TIG 222 AC DC HF LIFT - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

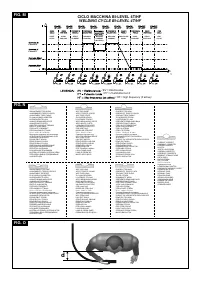

The value of current I . can vary between the minimum and the main welding current

nominal voltage of the main power supply.

1

value I .

2

_____________________________________________________________________________________________________________________

In order to disable the PULSED operation, rotate the Encoder in an anti-clockwise

direction until the message "OFF" is displayed.

WARNING! Failure to observe the above rules will make the (Class 1) safety

system installed by the manufacturer ineffective with consequent serious risks

to persons (e.g. electric shock) and objects (e.g. fire).

_____________________________________________________________________________________________________________________

5.4 CONNECTION OF THE WELDING CABLES

Led 4

_____________________________________________________________________________________________________________________

First function:

WARNING! BEFORE MAKING THE FOLLOWING CONNECTIONS MAKE

END SLOPE

SURE THE WELDING MACHINE IS SWITCHED OFF AND DISCONNECTED FROM

In TIG AC/DC mode, it allows adjustment of the welding current's END SLOPE upon

THE POWER SUPPLY OUTLET.

2

the release of the torch pushbutton; this adjustment allows to avoid formation of the

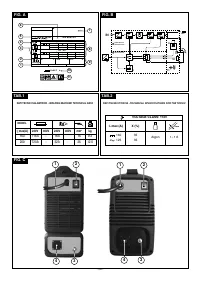

Table

(TAB. 1)

gives the recommended values for the welding cables (in mm )

crater at the end of the welding and permits the filling with welding material during the

depending on the maximum current supplied by the welding machine.

current down slope.

_____________________________________________________________________________________________________________________

Second function:

5.4.1 TIG welding

FREQUENCY

Torch connection

In TIG AC/DC PULSED mode ( I is different from "Off"), it allows the setting of the

1

- Insert the current-carrier cable in the specific fast-latch terminal (-). Link the three-

pulsing frequency.

pole connector (torch pushbutton) to the specific plug. Connect the gas pipe of the

In TIG AC mode with pulsing disabled( I = "OFF" ), it allows adjustment of the

1

torch to the specific fitting.

frequency in AC.

Connection of the welding current return cable

- This must be connected to the piece to be welded or to the metal bench on which it is

resting, as close as possible to the welding point in progress.

This cable must be connected to the terminal with symbol (+).

Connection to the gas bottle

- Screw in the gas regulator to the gas bottle's valve, interposing the specific reductor

Led 5

provided as an accessory.

- Connect the gas inflow pipe to the regulator and tighten the clamp supplied.

First function:

- Loosen the adjustment ring nut of the gas regulator before opening the gas bottle's

POST GAS

valve.

In TIG AC/DC mode, it allows adjustment of the post gas timing in seconds.

- Open the gas bottle and adjust the quantity of (l/min) according to the indicative data

Second function:

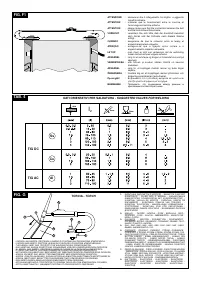

for the specific use; see table

(TAB. 4)

; any adjustments of the gas outflow may be

BALANCE

carried out during the welding operation, always turning the ring nut of the gas

In the pulsed-TIG AC/DC mode, it allows adjustment of the BALANCE. This

pressure regulator. Check the sealing of piping and connections.

parameter represents the relationship (in percentage) between the time during

WARNING! Always close the valve of the gas bottle at the end of work

which the current is at the greater level I and the total pulsing period. Furthermore, in

operations.

2

the TIG AC mode (with pulsing disabled), the parameter represented indicates the

relationship between the time during which the current's polarity is EN (negative

5.4.2 MMA WELDING

electrode) and the total period of the alternate current. The greater the positive value

Almost all coated electrodes are connected to the positive pole (+) of the power source;

the deeper is the welding penetration.

as an exception to the negative pole (-) for acid coated electrodes.

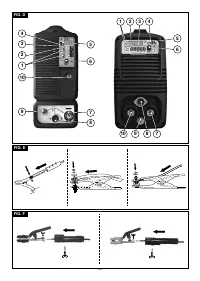

7-

Fast-latch negative plug (-) to connect the welding cable.

Connecting the electrode-holder clamp welding cable

8-

Connector for the torch pushbutton cable connection.

On the end take a special terminal that is used to close the uncovered part of the

9-

Fitting for the TIG torch gas pipe connection.

electrode.

10-

Fast-latch positive plug (+) to connect the welding cable.

This cable is connected to the terminal with the symbol (+)

Connecting the welding current return cable

This is connected to the piece being welded or to the metal bench supporting it, as close

5. INSTALLATION

as possible to the join being made.

_____________________________________________________________________________________________________________________

This cable is connected to the terminal with the symbol (-)

WARNING! CARRY OUT ALL INSTALLATION OPERATIONS AND

Warnings:

- Turn the welding cable connectors right down into the quick connections (if present),

ELECTRICAL CONNECTIONS WITH THE WELDING MACHINE COMPLETELY

to ensure a perfect electrical contact; otherwise the connectors themselves will

SWITCHED OFF AND DISCONNECTED FROM THE POWER SUPPLY OUTLET.

overheat, resulting in their rapid deterioration and loss of efficiency.

THE ELECTRICAL CONNECTIONS MUST BE MADE ONLY AND EXCLUSIVELY

- The welding cables should be as short as possible.

BY AUTHORISED OR QUALIFIED PERSONNEL.

_____________________________________________________________________________________________________________________

- Do not use metal structures which are not part of the workpiece to substitute the

return cable of the welding current: this could jeopardise safety and result in poor

5.1 PREPARATION

welding.

Unpack the welding machine, assemble the separate parts contained in the package.

6. WELDING: DESCRIPTION OF THE PROCEDURE

5.1.1 Assembling the return cable-clamp (FIG. E)

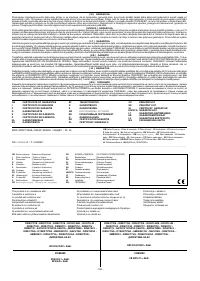

6.1 TIG WELDING

TIG welding is a welding procedure that exploits the heat produced by the electric arc

5.1.2 Assembling the welding cable-electrode holder clamp (FIG. F) (MMA)

that is struck, and maintained, between a non-consumable electrode (tungsten) and the

piece to be welded. The tungsten electrode is supported by a torch suitable for

5.1.3 How to lift the welding machine

transmitting the welding current to it and protecting the electrode itself and the weld pool

All the welding machines described in this handbook should be lifted using the handle or

from atmospheric oxidation, by the flow of an inert gas (usually argon: Ar 99.5) which

strap supplied if provided for the particular model (fitted as described in

FIG. F1

).

flows out of the ceramic nozzle

(FIG. G)

.

To achieve a good weld it is absolutely necessary to use the exact electrode diameter

5.2 POSITION OF THE WELDING MACHINE

with the exact current, see the table

(TAB. 4).

Choose the place to install the welding machine so that the cooling air inlets and outlets

The electrode usually protrudes from the ceramic nozzle by 2-3mm, but this may reach

are not obstructed (forced circulation by fan, if present); at the same time make sure that

8mm for corner welding.

conductive dusts, corrosive vapours, humidity etc. will not be sucked into the machine.

Welding is achieved by fusion of the edges of the joint. For properly prepared thin pieces

Leave at least 250mm free space around the welding machine.

(up to about 1mm) weld material is not needed

(FIG. H)

.

_____________________________________________________________________________________________________________________

For thicker pieces it is necessary to use filler rods of the same composition as the base

material and with an appropriate diameter, preparing the edges correctly

(FIG. I)

. To

WARNING! Position the welding machine on a flat surface with sufficient

achieve a good weld the pieces should be carefully cleaned and free of oxidation, oil,

carrying capacity for its weight, to prevent it from tipping or moving hazardously.

grease, solvents etc.

_____________________________________________________________________________________________________________________

6.1.1 HF and LIFT strike

5.3 CONNECTION TO THE MAIN POWER SUPPLY

HF strike:

- Before making any electrical connection, make sure the rating data of the welding

The electric arc is struck without contact between the tungsten electrode and the piece

machine correspond to the mains voltage and frequency available at the place of

being welded, by means of a spark generated by a high frequency device. This strike

installation.

mode does not entail either tungsten inclusions in the weld pool or electrode wear and

- The welding machine should only be connected to a power supply system with the

gives an easy start in all welding positions.

neutral conductor connected to earth.

Procedure:

- To ensure protection against indirect contact use residual current devices of the

Press the torch button, bringing the tip of the electrode close to the piece (2 -3mm), wait

following types:

for the arc strike transferred by the HF pulses and, when the arch has struck, form the

- Type A (

) for single phase machines;

weld pool on the piece and proceed along the joint.

If there are difficulties in striking the arc even though the presence of gas is confirmed

- Type B (

) for 3-phase machines.

and the HF discharges are visible, do not insist for long in subjecting the electrode to HF

- To comply with the requirements of the EN 61000-3-11 (Flicker) standard we

action, but check the integrity of the surface and the shape of the tip, dressing it on the

recommend connecting the welding machine to interface points of the power supply

grinding wheel if necessary. At the end of the cycle the current will fall at the slope down

that have an impedance of less than Zmax = 0.227ohm (1

~

).

setting.

- the welding machine does not fall within the requisites of IEC/EN 61000-3-12

standard.

LIFT strike:

Should it be connected to a public mains system, it is the installer's responsibility to

The electric arc is struck by moving the tungsten electrode away from the piece to be

verify that the welding machine itself is suitable for connecting to it (if necessary,

welded. This strike mode causes less electrical-radiation disturbance and reduces

consult the distribution network company).

tungsten inclusions and electrode wear to a minimum.

Procedure:

5.3.1 Plug and outlet

Place the tip of the electrode on the piece, using gentle pressure. Press the torch button

Connect a normalised plug (2P + T (1

~

)) - having sufficient capacity- to the power cable

right down and lift the electrode 2-3mm with a few moments' delay, thus striking the arc.

and prepare a mains outlet fitted with fuses or an automatic circuit-breaker; the special

Initially the welding machine supplies a current I

, after a few moments the welding

BASE

earth terminal should be connected to the earth conductor (yellow-green) of the power

current setting will be supplied. At the end of the cycle the current will fall to zero at the

supply line. Table

(TAB.1)

shows the recommended delayed fuse sizes in amps, chosen

slope down setting.

according to the max. nominal current supplied by the welding machine, and the

e

Hz

BAL

- 7 -