Сварочное оборудование Telwin TECHNOLOGY TIG 222 AC DC HF LIFT - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

- MMA welding kit.

- Remote control with two potentiometers:

- TIG welding kit.

The first potentiometer regulates the main current. The second potentiometer

- Self-darkening mask: with fixed or adjustable filter.

adjusts another parameter which is dependent on the active welding mode. By

- Gas connector and pipe for hook-up with Argon bottle.

rotating this potentiometer, the parameter being adjusted is displayed (which can

- Pressure reducing valve with gauge.

no longer be controlled by means of the knob on the panel). The meaning of the

- Torch for TIG welding.

second potentiometer is: ARC FORCE if in MMA mode and END SLOPE if in TIG

mode.

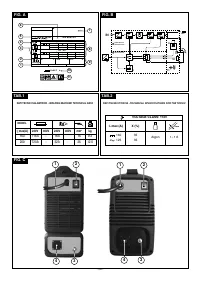

3. TECHNICAL DATA

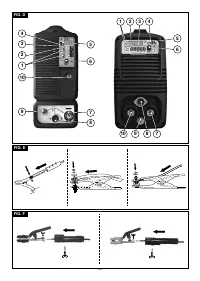

4.2.2 Front panel (FIG. D)

3.1 DATA PLATE (FIG. A)

1- Operating mode selectors:

The most important data regarding use and performance of the welding machine are

summarised on the rating plate and have the following meaning:

1-

Protection rating of the covering.

2-

Symbol for power supply line:

1~: single phase alternating voltage;

TIG/MMA mode selector:

3~: three phase alternating voltage.

Operating mode: TIG 2-STROKE, TIG 4-STROKE and MMA mode

3-

Symbol

S

: indicates that welding operations may be carried out in environments with

heightened risk of electric shock (e.g. very close to large metallic volumes).

.

4-

Symbol for welding procedure provided.

5-

Symbol for internal structure of the welding machine.

6-

EUROPEAN standard of reference, for safety and construction of arc welding

machines.

7-

Manufacturer's serial number for welding machine identification (indispensable for

TIG mode selector:

technical assistance, requesting spare parts, discovering product origin).

8-

Performance of the welding circuit:

Operating mode: TIG DC with HF striking, TIG DC with LIFT, TIG AC striking.

- U :

maximum no-load voltage (open welding circuit).

2- Leds

for welding parameters setting.

0

Fixed led: first function (black field);

- I /U :

current and corresponding normalised voltage that the welding machine can

2

2

Flashing led: second function (yellow field).

supply during welding.

3- Alphanumeric display .

- X :

Duty cycle: indicates the time for which the welding machine can supply the

4- Green led

indicating output voltage presence.

corresponding current (same column). It is expressed as %, based on a 10 minutes

5- Yellow led:

normally off; when lit, it indicates the blocking of the welding machine

cycle (e.g. 60% = 6 minutes working, 4 minutes pause, and so on).

due to the intervention of one of the following protections:

If the usage factors (on the plate, referring to a 40°C environment) are exceeded,

- Thermal protection: if an excessive temperature is reached within the welding

the thermal safeguard will trigger (the welding machine will remain in standby until

machine, the machine remains switched on without providing current until normal

its temperature returns within the allowed limits).

temperature is reached. The resetting is automatic.

- A/V-A/V:

shows the range of adjustment for the welding current (minimum

- Protection against line over-voltage an under-voltage: it blocks the welding

maximum) at the corresponding arc voltage.

machine if the line voltage is too high (greater than 264V ac) or too low (less than

9-

Technical specifications for power supply line:

190V ac).

- U :

Alternating voltage and power supply frequency of welding machine (allowed

1

- Protection against short circuits: if a short circuit has taken place with a duration

limit ±10%).

exceeding 1.5 seconds (electrode sticking) the welding machine is blocked.

- I

: Maximum current absorbed by the line.

1 max

The resetting is automatic.

- I

:

: Effective current supplied.

The coding on display is the following:

1eff

"AL. 1": anomaly in the primary power supply: the power supply voltage is out

10-

:

Size of delayed action fuses to be used to protect the power line.

of range +/- 15% as related to the nominal value on the tag.

11-

Symbols referring to safety regulations, whose meaning is given in chapter 1

WARNING: By exceeding the upper voltage limit specified above will seriously

“General safety considerations for arc welding”.

damage the device.

Note: The data plate shown above is an example to give the meaning of the symbols and

"AL. 2" kicking-in of one of the two safety thermostats due to the overheating

numbers; the exact values of technical data for the welding machine in your possession

of the welding machine.

must be checked directly on the data plate of the welding machine itself.

6- Button and Encoder

for the selection and setting of welding parameters.

Allows the selection of one of the available parameters associated with the welding

3.2 OTHER TECHNICAL DATA

mode/current indicated by the switching on of one of the Leds (2).

- WELDING MACHINE: see table 1 (TAB.1)

- TORCH:

see table 2 (TAB.2)

The welding machine weight is shown in table 1 (TAB. 1).

4. DESCRIPTION OF THE WELDING MACHINE

Led 1

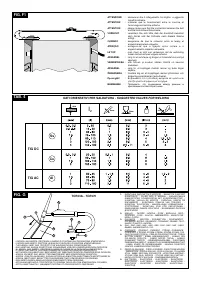

4.1 BLOCK DIAGRAM

The welding machine consists basically of power and control modules made on PCB's

First function:

and optimised to achieve perfect reliability and reduced maintenance.

Arc Force

This welding machine is controlled by a microprocessor that allows a large number of

In the MMA mode, it allows adjustment of the "Arc Force" dynamic over-current

parameter settings so as to achieve perfect welding in any condition and with any

(adjustment 0-100%) with indication on display of the percentage increment as

material. However, to make the best use of its properties it is necessary to be fully aware

compared with the pre-selected welding current's value. This adjustment improves

of its possibilities.

the fluidity of the welding and prevents the electrode sticking to the piece.

Pregas

Description (FIG. B)

In the TIG mode, it allows adjustment of the pregas time in seconds.

1-

Single phase power supply input, rectifier unit and levelling capacitors.

Second function:

2-

Transistor (IGBT) switching bridge and drivers;

commutes the rectified power

Electrode diameter

supply voltage to high frequency alternating voltage and adjusts the power

In the TIG AC mode, it allows adjustment of the electrode diameter in mm.

according to the required welding current/voltage.

3-

High frequency transformer;

the voltage converted by block 2 powers the

primary winding; its function is to adjust the voltage and current to the values

needed for the arc welding procedure and at the same time to form galvanic

separation of the welding circuit from the power supply line.

4-

Secondary rectifier bridge with levelling inductance;

commutes the alternating

Led 2

voltage / current supplied by the secondary winding into very low ripple direct

current / voltage.

First function:

5-

Transistor switching bridge and drivers;

transforms the secondary output

INITIAL CURRENT

current from DC to AC for TIG AC welding.

In the TIG 4-stroke mode, it allows adjustment of the initial current which is

6-

Control and adjustment electronics;

controls the welding current value

maintained while the torch pushbutton remains pressed.

instantaneously and compares it with the operator's setting; modulates the control

Second function:

impulses from the IGBT drivers that make the adjustment.

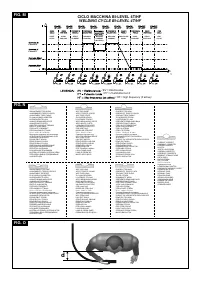

BI-LEVEL

7-

Welding machine operation control logic;

sets the welding cycles, controls the

In TIG 4-stroke mode, it activates the BI-LEVEL function and allows adjustment of the

actuators, supervises the safety systems.

second-level current permitting manual selection (from the torch pushbutton during

8-

Settings panel

and display of parameters and operating modes.

the welding operation) between two different current levels: I and I . The I main level

9-

HF strike generator.

2

1

2

current is defined by the welding current set, whereas level I can be changed by

10- Protective gas solenoid valve EV.

1

means of the Encoder, between the current's minimum value and the value of the

11- Welding machine cooling fan.

main welding current.

12- Remote control.

In order to disable the operation in BI-LEVEL, rotate the Encoder in an anti-clockwise

direction, until the message "OFF" is displayed.

4.2 CONTROL, ADJUSTMENT AND CONNECTION DEVICES

4.2.1 BACK PANEL (FIG. C)

1-

Power supply cable 2P + (P.E).

2-

Main switch O/OFF - I/ON.

3-

Gas pipe connector (bottle pressure reducing valve welding machine).

4-

Remote control connector:

Led 3

Using the special 14-pin connector on the back, it is possible to attach different

types of remote control to the welding machine. Each device will be recognised

automatically and can be used to adjust the following parameters:

First function:

- Remote control with one potentiometer:

Main current

turning the potentiometer knob will change the main current from the minimum to

In TIG DC and MMA mode, it allows adjustment of the welding current's mean value.

the maximum. The main current is adjusted only and exclusively by the remote

In TIG AC mode, it allows adjustment of the welding current's effective value.

control.

Second function:

- Pedal remote control:

PULSED MODE OPERATION

The current value is determined by the position of the pedal. In addition, in TIG 2-

In TIG AC/DC mode, it activates the PULSED operation and allows adjustment of the

STROKE mode pressing the pedal gives the start command to the machine

second level current I , which can be alternated with the main current I in the pulse.

1

2

instead of the torch button.

TIG-2T

TIG-4T

MMA

DC-HF

DC-LIFT

AC-HF

ARC

FORCE

s

- 6 -