Электропилы Bosch GCM 12 SD - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

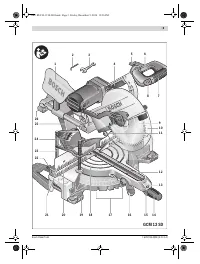

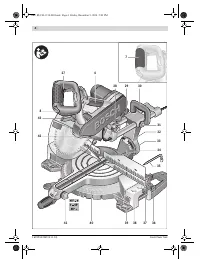

34

| English

1 609 92A 0XM | (5.12.14)

Bosch Power Tools

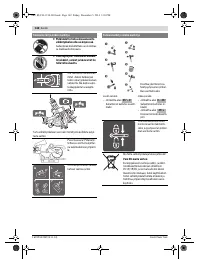

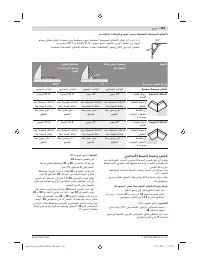

Checking and Adjusting the Basic Adjustment

To ensure precise cuts, the basic adjustment of the machine

must be checked and adjusted as necessary after intensive

use.

A certain level of experience and appropriate specialty tools

are required for this.

A Bosch after-sales service station will handle this mainte-

nance task quickly and reliably.

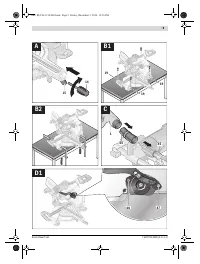

Setting the Standard Bevel Angle 0 ° (Vertical)

– Bring the machine into the transport position.

– Turn the saw table

18

to the 0 ° detent

17

. The lever

15

must be felt to engage in the detent.

Checking:

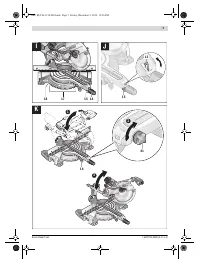

(see figure S1)

– Set an angle gauge to 90 ° and place it on the saw table

18

.

The leg of the angle gauge must be flush with the saw blade

9

over the complete length.

Adjusting:

(see figure S2)

– Loosen the lock lever

16

.

– Loosen set screws

60

and

61

with the supplied open-end

spanner

3

(10 mm).

– Loosen set screw

62

(approx. 3 turns) with the supplied

hex key

35

(4 mm).

– Screw set screw

59

(10 mm) in or out until the leg of the

angle gauge is flush with the saw blade over the complete

length.

– Retighten the lock lever

16

again.

Afterwards, tighten set screw

62

first, and then set screws

60

and

61

.

When the angle indicators

33

and

24

are not in line with the 0 °

marks of scale

32

after adjusting, loosen the fastening screws

of the angle indicators with the supplied cross-head screwdriv-

er

35

and align the angle indicators alongside the 0 ° marks.

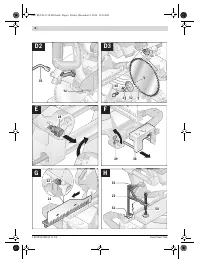

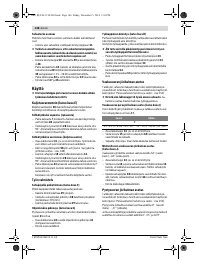

Setting the Standard 45 ° Bevel Angle (Leftward)

– Bring the power tool into the working position.

– Turn the saw table

18

to the 0 ° detent

17

. The lever

15

must be felt to engage in the detent.

– Pull the left fence extension

21

completely outward.

– Loosen the lock lever

16

and tilt the tool arm leftward to

the stop (45 °) by the handle

7

.

Checking:

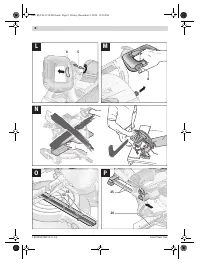

(see figure T1)

– Set an angle gauge to 45 ° and place it on the saw table

18

.

The leg of the angle gauge must be flush with the saw blade

9

over the complete length.

Adjusting:

(see figure T2)

– Screw set screw

63

(10 mm) in or out until the leg of the

angle gauge is flush with the saw blade over the complete

length.

– Retighten the lock lever

16

again.

When the angle indicators

33

and

24

are not in line with the

45 ° marks of scale

32

after adjusting, firstly once more check

the 0 ° setting for the bevel angle and the angle indicators.

Then repeat the adjustment of the 45 ° bevel angle.

Adjusting the Clamping Force of Lock Lever 16

(see figure T2)

The clamping force of lock lever

16

can be readjusted.

Checking:

– The clamping force of the clamping lever must securely

hold the position of the tool arm at any bevel angle.

Adjusting:

– Loosen the lock lever

16

.

– Turn set screw

64

in anticlockwise direction with the sup-

plied open-end spanner

3

(17 mm) to reduce the clamping

force, or increase the clamping force by turning in clock-

wise direction.

– Adjust a vertical bevel angle, retighten lock lever

16

and

check if the desired clamping force has been reached.

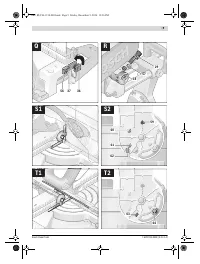

Adjusting the Clamping Force of Clamp 5 (see figure U)

The clamping force of the handle clamp

5

can be readjusted.

Checking:

– The clamping force of the clamp must securely hold the

handle in any of the 4 possible positions.

Adjusting:

– Open clamp

5

.

– Turn both set screws

65

in anticlockwise direction with the

supplied hex key

2

(1.5 mm) to reduce the clamping force,

or increase the clamping force by turning in clockwise di-

rection.

Always adjust both set screws to the same height.

– Shut clamp

5

and check if the desired clamping force has

been reached.

Aligning the Angle Indicator (Horizontally) (see figure V)

– Bring the power tool into the working position.

– Turn the saw table

18

to the 0 ° detent

17

. The lever

15

must be felt to engage in the detent.

Checking:

The angle indicator

66

must be in alignment with the 0 ° mark

of the scale

40

.

Adjusting:

– Loosen the fastening screw of the angle indicator with the

supplied cross-head screwdriver

35

and align the angle in-

dicator alongside the 0 ° mark.

– Retighten the screw again.

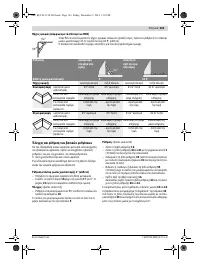

Aligning the Fence

– Bring the machine into the transport position.

– Turn the saw table

18

to the 0 ° detent

17

. The lever

15

must be felt to engage in the detent.

Checking:

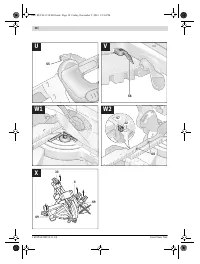

(see figure W1)

– Adjust an angle gauge to 90 ° and position it flush with the

saw blade

9

between the fence

20

and the saw blade on

the saw table

18

.

The leg of the angle gauge must be flush with the fence over

the complete length.

OBJ_BUCH-1130-003.book Page 34 Friday, December 5, 2014 12:37 PM

Содержание

- 231 или подвижных частей электроинструмента.

- 232 Не становитесь на электроинструмент.; Символы; Символы и их значение

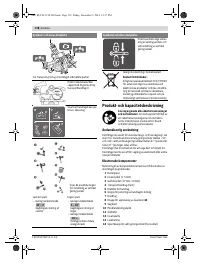

- 234 Описание продукта и услуг; Применение по назначению

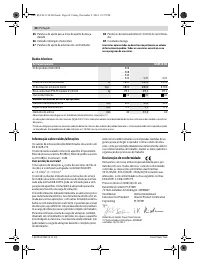

- 235 Технические данные; Применяйте средства защиты органов слуха!; Заявление о соответствии; Сборка; Комплект поставки; Панельная пила; Размеры пильных дисков

- 236 Стационарный или временный монтаж; Монтаж на верстаке производства Bosch; Отсос пыли и стружки; Внешняя система пылеотсоса

- 237 Демонтаж пильного диска; Работа с инструментом; Подготовка к эксплуатации

- 238 Настройка горизонтального угла распила; угол распила

- 239 Включение электроинструмента; Угол распила

- 240 Резание с тяговым движением; Обработка профильных реек (плинтусов и потолочных планок); Плинтусы

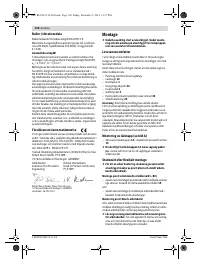

- 241 Основные настройки – контроль и коррекция; Настройка угла наклона в 0 °

- 242 Настройка упорной планки

- 243 Техобслуживание и сервис; Техобслуживание и очистка; Очистка; Принадлежности; Россия; Беларусь; Утилизация