Электропилы Bosch GCM 12 SD - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

30

| English

1 609 92A 0XM | (5.12.14)

Bosch Power Tools

Take care during the mounting that the cutting direc-

tion of the teeth (direction of the arrow on the saw

blade) agrees with the direction of the arrow on the re-

tracting blade guard!

– Mount the clamping flange

50

, the washer

49

and the hex-

agon bolt

48

.

Press spindle lock

42

until it engages and tighten hexagon

bolt

48

with the supplied socket spanner

35

in anticlock-

wise direction with a tightening torque of approx.

15 – 23 Nm.

– Push the locking lever

43

and guide the retracting blade

guard

10

down again.

– Retighten the screws

47

and

46

.

Operation

Before any work on the machine itself, pull the mains

plug.

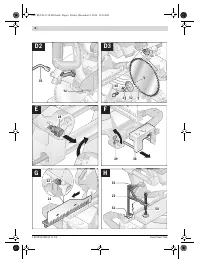

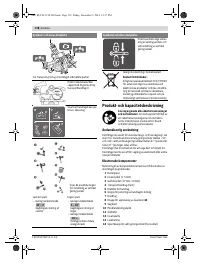

Transport Safety (see figure E)

The transport safety-lock

28

enables easier handling of the

machine when transporting to various working locations.

Releasing the Machine (Working Position)

– Push the tool arm by the handle

7

down a little in order to

relieve the transport safety-lock

28

.

– Pull the transport safety-lock

28

all the way outward and

turn it by 90 °. Allow the transport safety-lock to engage in

this position.

– Guide the tool arm slowly upward.

Securing the Machine (Transport Position)

– Loosen the locking screw

31

if tightened. Pull the tool arm

completely to the front and tighten the locking screw

again.

– Screw the depth stop

58

completely to the top (see “Ad-

justing the Depth Stop”, page 32).

– To lock the saw table

18

, tighten the locking knob

14

.

– Pull the transport safety-lock

28

all the way outward and

turn it by 90 °. Allow the transport safety-lock to engage in

this position.

– Push the locking lever

43

and at the same time lower the

tool arm via handle

7

until the transport safety-lock engag-

es in the end position.

The tool arm is now securely locked for transport.

Preparing for Operation

Extending the Saw Table (see figure F)

Long workpieces must be underlaid or supported at their free

end.

– Push tensioning lever

39

upward.

– Pull out saw-table extension

38

to the desired length (max.

225 mm).

– Lock in place by pushing tensioning lever

39

down again.

Extending the Fence (see figure G)

For bevel angles, the fence extensions

21

must be moved.

– Loosen the locking screw

22

and pull the fence extension

21

completely outward.

– Retighten the screw again.

Clamping the Workpiece (see figure H)

To ensure optimum working safety, the workpiece must al-

ways be firmly clamped.

Do not saw workpieces that are too small to clamp.

While clamping the workpiece, do not reach under the

clamping lever of the quick-action clamp with your fin-

gers.

– Press the workpiece firmly against the fence

20

.

– Insert the quick-action clamp

23

into one of the holes

52

intended for this purpose.

– Adapt the quick-action clamp to the workpiece by turning

the threaded rod

54

.

– Push on the clamping lever

53

in order to clamp the work-

piece.

Adjusting Mitre Angles

To ensure precise cuts, the basic adjustment of the machine

must be checked and adjusted as necessary after intensive use

(see “Checking and Adjusting the Basic Adjustment”,

page 34).

Always tighten the locking knob 14 firmly before saw-

ing.

Otherwise the saw blade can become wedged in the

workpiece.

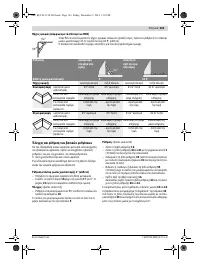

Adjusting Standard Mitre Angles (see figure I)

For quick and precise adjustment of commonly used mitre an-

gles, detents

17

have been provided for on the saw table:

– Loosen the locking knob

14

in case it is tightened.

– Pull lever

15

and rotate the saw table

18

left or right to the

requested detent.

– Release the lever again. The lever must be felt to engage in

the detent.

Adjusting Any Mitre Angle (see figure J)

The mitre angle can be set in the range from 52 ° (left side) to

60 ° (right side).

– Loosen the locking knob

14

in case it is tightened.

– Pull lever

15

and at the same time push the locking bracket

13

until it engages in the groove intended for this. The saw

table can be moved freely now.

– Turn the saw table

18

left or right by the locking knob until

the angle indicator

66

indicates the requested mitre angle.

– Tighten the locking knob

14

again.

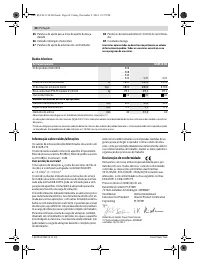

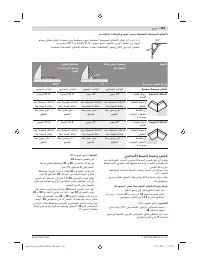

Adjusting Bevel Angles

To ensure precise cuts, the basic adjustment of the machine

must be checked and adjusted as necessary after intensive

use (see “Checking and Adjusting the Basic Adjustment”,

page 34).

The vertical bevel angle can be adjusted in a range from 47 °

(leftward) to 47 ° (rightward).

For quick and precise adjustment of commonly used bevel an-

gles, stops are provided for 0 °, 45 ° and 33.9 ° angles.

Left

Right

0 °

15 °; 22.5 °; 31.6 °; 45 °; 52 ° 15 °; 22.5 °; 31.6 °; 45 °; 60 °

OBJ_BUCH-1130-003.book Page 30 Friday, December 5, 2014 12:37 PM

Содержание

- 231 или подвижных частей электроинструмента.

- 232 Не становитесь на электроинструмент.; Символы; Символы и их значение

- 234 Описание продукта и услуг; Применение по назначению

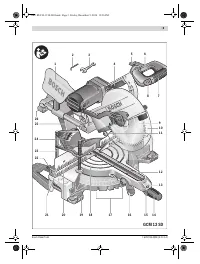

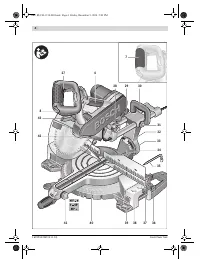

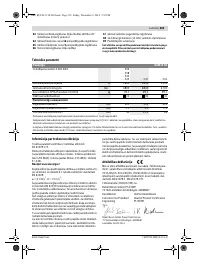

- 235 Технические данные; Применяйте средства защиты органов слуха!; Заявление о соответствии; Сборка; Комплект поставки; Панельная пила; Размеры пильных дисков

- 236 Стационарный или временный монтаж; Монтаж на верстаке производства Bosch; Отсос пыли и стружки; Внешняя система пылеотсоса

- 237 Демонтаж пильного диска; Работа с инструментом; Подготовка к эксплуатации

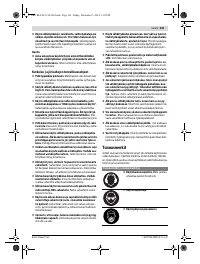

- 238 Настройка горизонтального угла распила; угол распила

- 239 Включение электроинструмента; Угол распила

- 240 Резание с тяговым движением; Обработка профильных реек (плинтусов и потолочных планок); Плинтусы

- 241 Основные настройки – контроль и коррекция; Настройка угла наклона в 0 °

- 242 Настройка упорной планки

- 243 Техобслуживание и сервис; Техобслуживание и очистка; Очистка; Принадлежности; Россия; Беларусь; Утилизация