Пилы торцовочные Bosch 0.601.B19.100 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

30

| English

1 609 92A 04K | (31.10.12)

Bosch Power Tools

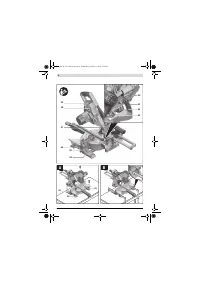

Position of the Operator (see figure N)

Do not stand in a line with the saw blade in front of the

machine. Always stand aside of the saw blade.

This pro-

tects your body against possible kickback.

– Keep hands, fingers and arms away from the rotating saw

blade.

– Do not cross your arms when operating the tool arm.

Permissible Workpiece Dimensions

Maximal

workpiece sizes:

Minimal

workpiece sizes (= all workpieces that can be

clamped left or right from the saw blade with the supplied ma-

terial clamp

29

):100 x 40 mm (length x width)

Cutting depth, max.

(0 ° /0 ° ): 70 mm

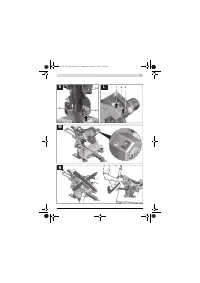

Replacing Insert Plates (see figure O)

The red insert plates

18

can become worn after prolonged

use of the machine.

Replace defective insert plates.

– Bring the power tool into the working position.

– Unscrew the screws

49

with an Allen key (size 4 mm) and

remove the old insert plates.

– Insert the new right-hand insert plate.

– Screw the insert plate as far as possible to the right with

the screws

49

so that the saw blade does not come into

contact with the insert plate over the complete length of

the possible slide motion.

– Repeat the work steps in the same manner for the left-hand

insert plate.

Sawing

Always tighten the locking knob 20 firmly before saw-

ing.

Otherwise the saw blade can become wedged in the

workpiece.

Sawing without Slide Movement (Cutting Off)

(see figure P)

– For cuts without slide movement (small workpieces), loos-

en the locking screw

33

in case it is tightened. Slide the

tool arm to the stop in the direction of the fence

14

and

retighten the locking screw

33

.

– Set the desired mitre angle.

– Firmly clamp the workpiece as appropriate for its dimen-

sions.

– Switch on the machine.

– Press locking switch

9

and slowly guide the tool arm down-

ward by the handle

8

.

– Saw through the workpiece applying uniform feed.

– Switch off the machine and wait until the saw blade has

come to a complete stop.

– Guide the tool arm slowly upward.

Sawing with Slide Movement

– For cuts using the slide device

1

(wide workpieces), loosen

the locking screw

33

in case it is tightened.

– Set the desired mitre angle.

– Firmly clamp the workpiece as appropriate for its dimen-

sions.

– Pull the tool arm away from the fence

14

far enough so that

the saw blade is in front of the workpiece.

– Switch on the machine.

– Press locking switch

9

and slowly guide the tool arm down-

ward by the handle

8

.

– Press the tool arm in the direction of the fence

14

and saw

through the workpiece applying uniform feed.

– Switch off the machine and wait until the saw blade has

come to a complete stop.

– Guide the tool arm slowly upward.

Sawing Workpieces of the Same Length (see figure Q)

The material stop

36

(accessory) can be used for easily saw-

ing workpieces to the same length.

The material stop can be mounted on either side of the saw ta-

ble extension

13

.

– Loosen lock screw

50

and swing the material stop

36

over

clamping screw

51

.

– Retighten lock screw

50

.

– Adjust the saw table extension

13

to the desired length

(see “Extending the Saw Table”, page 28).

Adjusting the Depth Stop (Sawing Grooves) (see figure R)

The depth stop must be adjusted when a trench gap is to be

sawed.

– Swivel the depth stop

32

outward.

– Press locking lever

9

and tilt the tool arm to the desired po-

sition.

– Turn adjusting screw

4

, until the screw end touches depth

stop

32

.

– Guide the tool arm slowly upward.

Special Workpieces

When sawing curved or round workpieces, these must be es-

pecially secured against slipping. At the cutting line, no gap

may exist between workpiece, fence and saw table.

Provide for special fixtures, if required.

Checking and Adjusting the Basic Adjustment

Before any work on the machine itself, pull the mains

plug.

To ensure precise cuts, the basic adjustment of the machine

must be checked and adjusted as necessary after intensive

use.

A certain level of experience and appropriate specialty tools

are required for this.

A Bosch after-sales service station will handle this mainte-

nance task quickly and reliably.

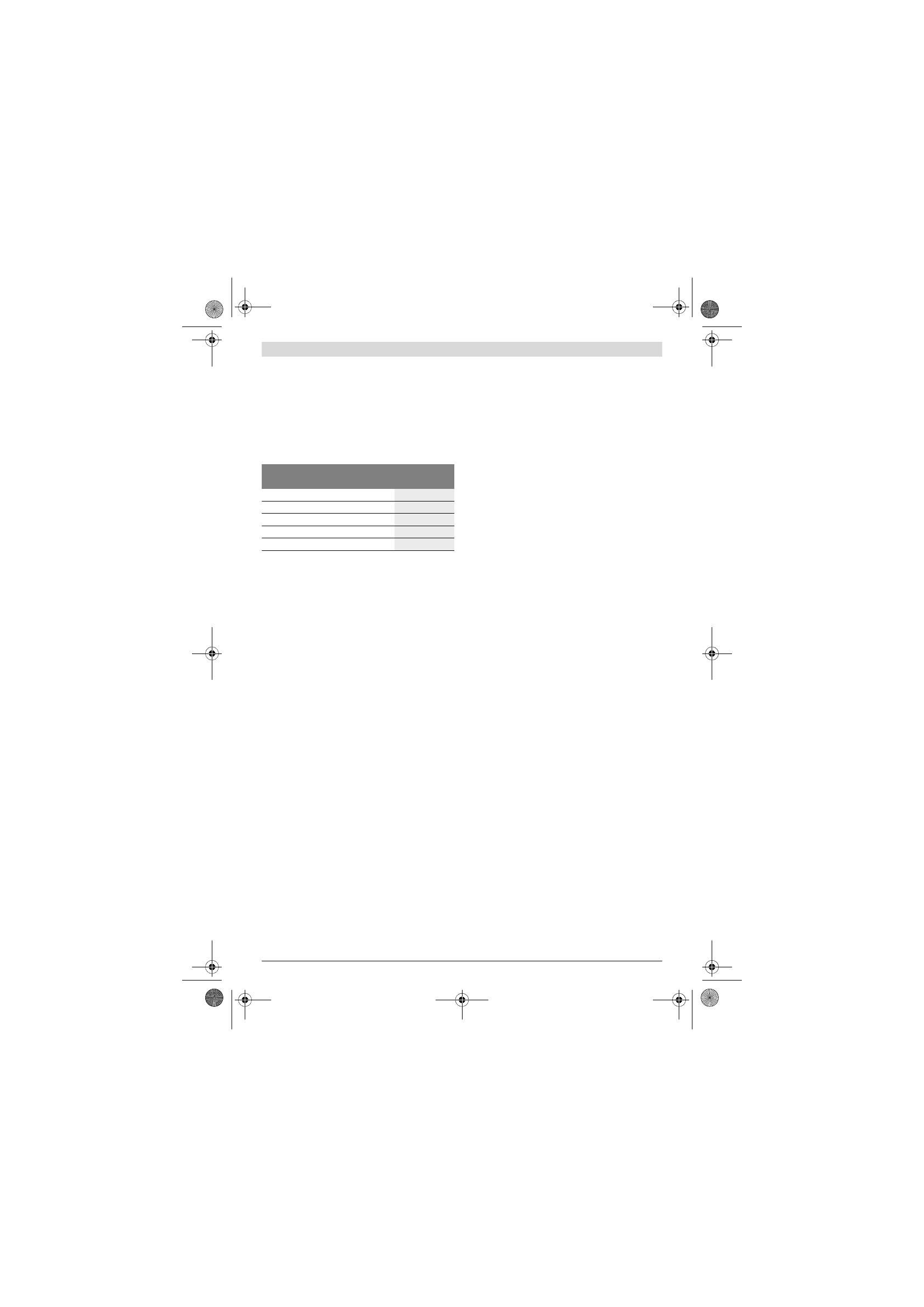

Mitre/Bevel Angle

Height x Width

[mm]

Horizontal

Vertical

0 °

0 °

70 x 312

45 ° (leftward/rightward)

0 °

70 x 225

0 °

45 °

45 x 312

45 ° (leftward)

45 °

45 x 225

45 ° (rightward)

45 °

45 x 225

OBJ_BUCH-1736-002.book Page 30 Wednesday, October 31, 2012 3:55 PM

Содержание

- 198 Применение электроинструмента и обращение с ним

- 199 Закрепляйте заготовку.; Символы; Символы и их значение

- 200 Описание продукта и услуг; Применение по назначению; Зажимной рычаг зажат:

- 201 Технические данные; Применяйте средства защиты органов слуха!; Заявление о соответствии; Панельная пила; Размеры пильных дисков

- 202 Сборка; Комплект поставки; Монтаж на верстаке производства Bosch; Отсос пыли и стружки; Избегайте скопления пыли на рабочем месте.

- 203 Демонтаж пильного диска; Работа с инструментом; Подготовка к эксплуатации; Угол распила

- 204 Настройка горизонтального угла распила; слева

- 205 Указания по применению; Общие указания для пиления; Пиление; Резание с тяговым движением

- 206 Специальные заготовки; Основные настройки; Настройка угла наклона в 0

- 207 Техобслуживание и сервис; Техобслуживание и очистка; Очистка; Принадлежности; Товарный No

- 208 Россия; Утилизация

Характеристики

Остались вопросы?Не нашли свой ответ в руководстве или возникли другие проблемы? Задайте свой вопрос в форме ниже с подробным описанием вашей ситуации, чтобы другие люди и специалисты смогли дать на него ответ. Если вы знаете как решить проблему другого человека, пожалуйста, подскажите ему :)