Бензопилы GRAPHITE 58G952 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

20

•

Clean plastic par ts with mild detergent and a sponge.

•

You can proceed with maintenance actions only described

within this instruction manual.

A

ny other action can be carried

out only by authorized ser vice.

•

Do not make any changes in chain saw construction.

•

When not in use, chain saw should be stored clean, on flat

sur face, in dr y place and beyond reach of children.

When storing it is impor tant to avoid deposition of rubber

par ticles in basic par ts of the fuel system, such as carburettor,

fuel filter, fuel line and fuel tank. Fuels with alcohol additives

(ethanol or methanol) may absorb moisture, and that during

storing causes separation of fuel blend ingredients and

formation of acids. Acidic petrol may damage the engine.

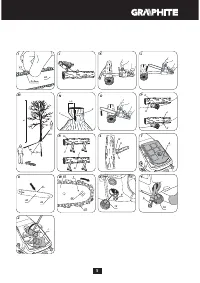

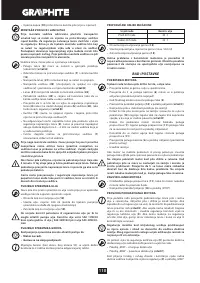

A I R F I LT E R

Dir ty air filter reduces efficiency of combustion engine and

causes increase of fuel consumption. Clean the air filter after

each 5 hours of the saw operation.

•

Clean the air filter lid (

4

) and its surroundings, so the dir t does

not get into carburettor chamber after the lid is removed.

•

Unscrew knob for air filter lid (

3

) and remove air filter lid (

4

).

•

Remove air filter (

d

) (

fig. T

).

•

Use water with soap to clean the filter, wash with clean water

and dr y thoroughly.

•

I

nstall air filter. Ensure the grooves on the air filter rim match

protrusions on the air filter lid (

4

).

•

When installing the air filter lid (

4

) make sure to properly

place ignition plug wire and access sleeves for carburettor

adjustment screws.

Do not wash the air filter in petrol or any other flammable

solvent to avoid fire hazard or appearance of dangerous

vapours.

C YL I N D E R F I N N I N G

Dust deposition on the cylinder finning may cause motor

overheating. Check regularly and clean the cylinder finning

when carr ying out maintenance of the air filter.

GUIDE BAR AND CHAIN

Check condition of the guide bar and chain ever y 5 hours of the

saw operation.

•

Set the ignition switch (

14

) to off position.

•

Loosen and unscrew the guide bar fixing nuts (

7

).

•

Remove the casing (

10

) and disassemble guide bar (

20

) and

chain (

21

).

•

Clean oil holes and groove (

e

) in the guide bar (

20

) (

fig. U

).

•

Lubricate tip chain wheel of the guide bar (

22

) through the

hole (

f

) located on the guide bar tip (

fig. W

).

•

Check condition of the chain (

21

).

C H A I N S H A R P E N I N G

Pay attention to cutting tools. Cutting tools should be sharp and

clean, it allows efficient and safe operation. Operating the saw

with blunt chain causes quick wear of the chain, guide bar and

driving chain wheel, and breaking the chain in the worst case.

That is why it is impor tant to sharpen the chain on time.

Chain sharpening is a complex operation. Sharpening the

chain by yourself requires use of special tools and skills.

I

t is

recommended to entrust sharpening the chain to qualified

persons.

F U E L F I LT E R

•

Unscrew the fuel filler plug (

15

).

•

Use wire hook to remove the fuel filter (

g

) through the fuel

filler hole (

fig. X

).

•

Disassemble the fuel filter and wash it in petrol or replace with

a new one.

•

I

nstall the fuel filter in the tank.

•

Tighten the fuel filler plug (

15

).

When the filter has been dismantled use the wire hook to hold

up the end of the suction line.

Be careful during fuel filter installation to prevent

contamination from getting into the suction line.

O I L F I LT E R

•

Unscrew oil filler plug (

18

).

•

Use wire hook to remove the oil filter (

h

) through the oil filler

hole (

fig. Y

).

•

Wash the oil filter in petrol or replace with a new one.

•

Remove dir t from the tank.

•

I

nstall the oil filter in the tank.

•

Tighten oil filler plug (

18

).

When putting the oil filter into the tank make sure it reaches

front right corner.

I G N I T I O N P LU G

To maintain reliable operation of the device, check condition of

the ignition plug on a regular basis.

•

Remove air filter lid (

4

).

•

Remove air filter (

d

).

•

Remove wire (

i

) from the ignition plug.

•

Put on plug key (included) and unscrew the ignition plug (

fig.

Z

).

•

Clean and adjust spacing between contacts (0.65 mm) (replace

ignition plug when necessar y).

OTHER INSTRUC TIONS

Ensure there are no fuel leaks, loosened joints or damages of

main par ts, especially main handle joints and guide bar fixing.

When you find any damage, make sure it is repaired before next

use of the chain saw.

A

ll faults should be repaired by ser vice workshop authorized by

the manufacturer.

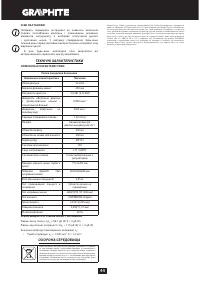

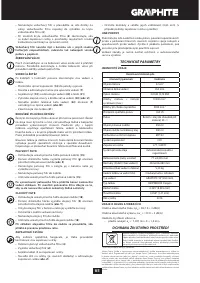

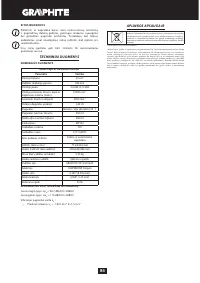

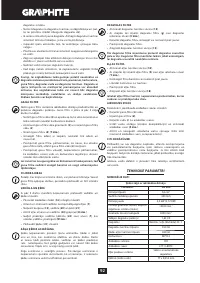

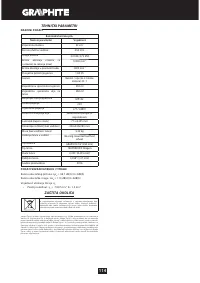

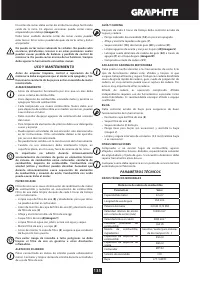

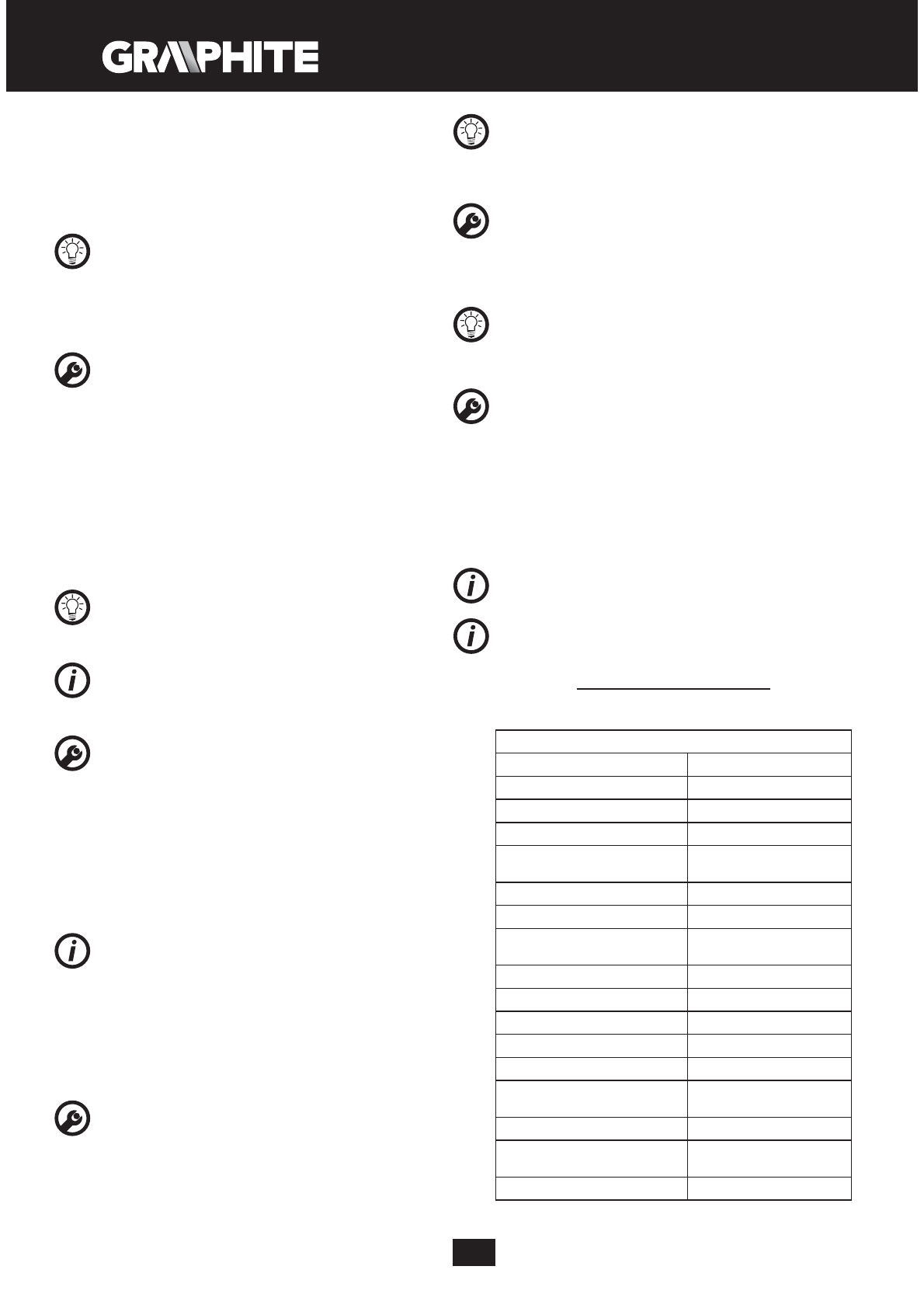

TECHNICAL PARAMETERS

R AT E D PA R A M E T E R S

Petrol Chain Saw

Rated parameter

Value

Engine displacement

52 cm

3

Guide bar working length

450 mm

Engine power

2,0 kW (2,72 K

M

)

Engine speed with cutting system

(maximum)

10500 min

-1

I

dle rotational speed

3000 min

-1

A

verage fuel consumption

1,63 l/h

Fuel

Petrol / oil (for 2-stroke

engines) 25:1

Fuel tank capacity

550 ml

Chain oil tank capacity

260 ml

Carburettor

M

P132

I

gnition system

CD

I

I

gnition plug

L7T / L8RTC

Oil feed system

A

utomated pump with

controller

Chain wheel (teeth x pitch)

7T x 8,255 mm

Dimensions (LxWxH) (w/o guide

bar)

400x240x280 mm

Weight (w/o guide bar and chain)

5,35 kg

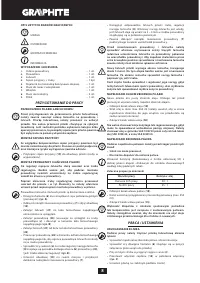

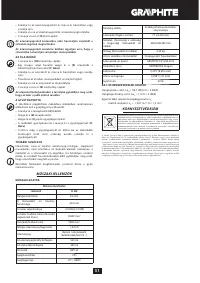

Содержание

- 31 ПОДГОТОВКА К РАБОТЕ; Использовать мас ло SAE

- 32 Проверьте свободное вращение цепи, цепь не

- 34 Запрещается валить деревья в с лучае:; ТЕХНИЧЕСКОЕ ОБСЛУЖИВАНИЕ

- 35 ТЕХНИЧЕСКИЕ ПАРАМЕТРЫ; Пила цепная бензиновая

- 36 ЗАЩИТА ОКРУЖАЮЩЕЙ СРЕДЫ; ИНФОРМАЦИЯ О ДАТЕ ИЗГОТОВЛЕНИЯ; Порядок расшифровки информации с ледующий:; ХХХ – год изготовления,