Варочная панель FALMEC Quantum (600) - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

20

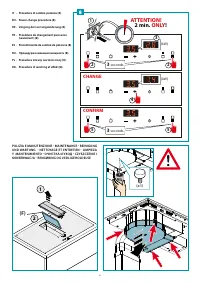

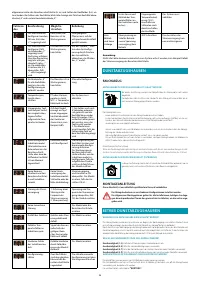

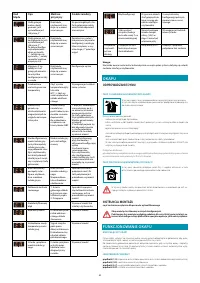

WHAT TO DO IN CASE OF COOKERS PROBLEMS

The cooker or cooking areas do not turn on:

· The cooker is not connected to the electric network.

· The protection fuse is released.

· Check if the block is not active.

· Keys are covered with water or grease.

· An object is placed on the keys.

The symbol is displayed

.

· There is no saucepan on the cooking area.

· The container used is not compatible with cooktops.

· The diameter of the saucepan bottom is too small compared to the cooking area.

The symbol [E] is displayed:

· Disconnect and connect the cooker.

· Contact the after-sales centre.

One of the area or the entire cooker turns o

ff

:

· The safety overheating system is active;

· The cooker or one cooking area remains on for too long;

· one or more keys are covered;

· one of the saucepans is empty and the bottom overheated.

The fan keeps on working after the cooker shutdown:

· This is not a malfunction: the fan keeps on protecting the electronic power unit of the

device.

· The fan stops automatically.

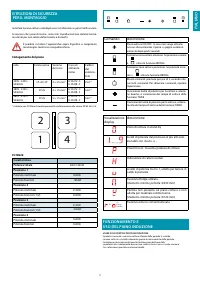

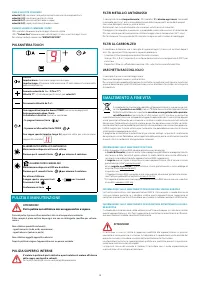

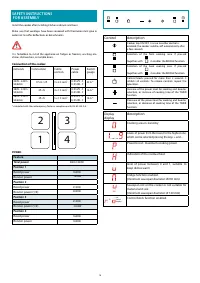

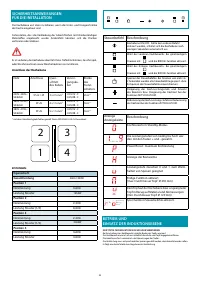

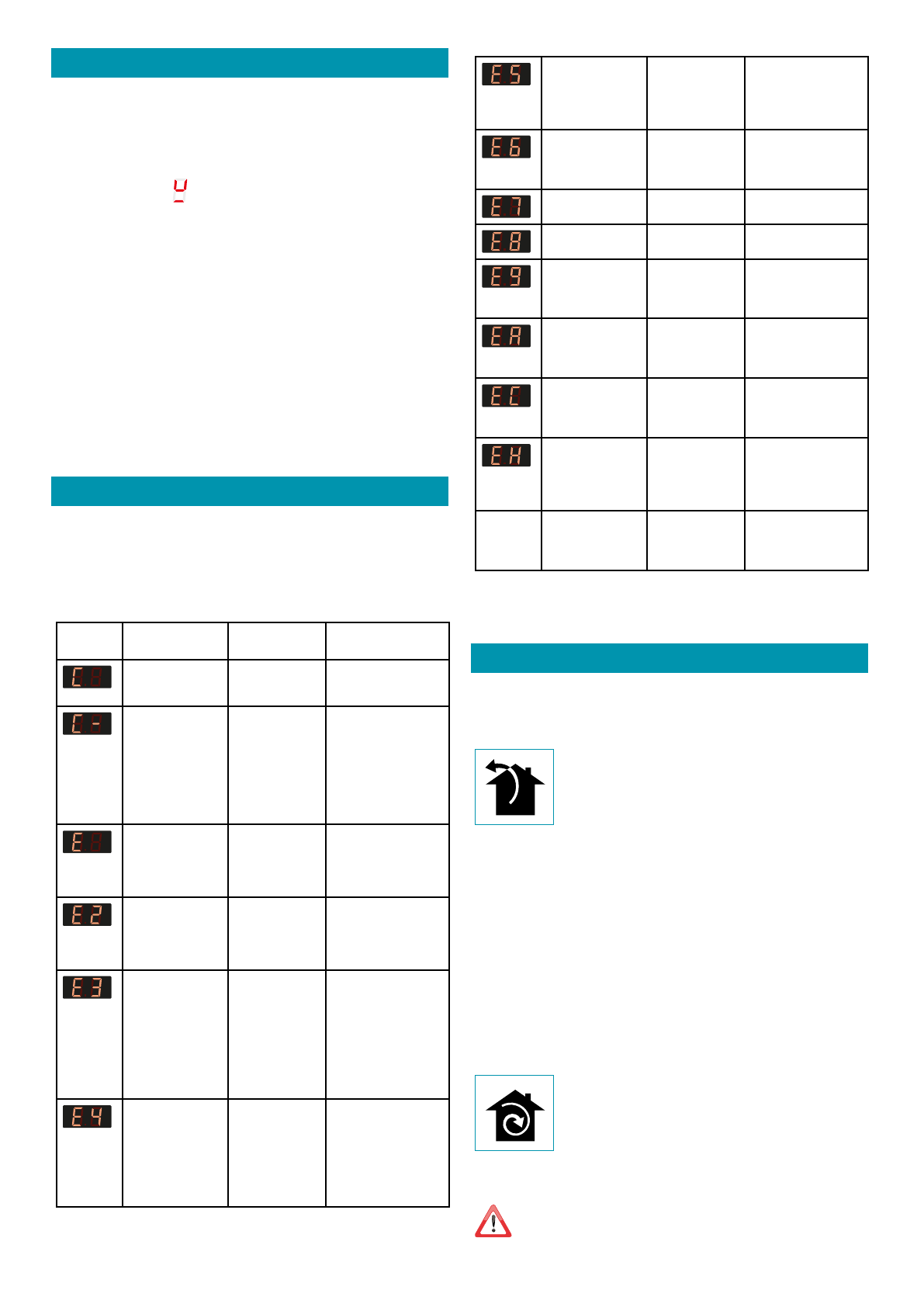

COOKERS ERROR CODES

For supporting a service technician in case of error, the UI displays error codes.

In combination with the provided document "error codes Basic 2" which includes datai-

led information a complete error matrix description is available.

E.G.O's standard error codes are listed following, customized UI can be di

ff

erent. In the

standard general UI eroors (Er xx) and cooking zone errors (E/x) di

ff

er. In case of cooking

zone errors the display of the incorrect cooking zone blinks alternative "E" and a hexco-

de "X".

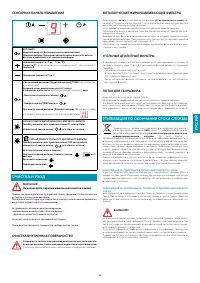

Error

code

Description

possible

causes

Remedy

.

The cooking zone

can be con

fi

gured if

a static "C" is shown

No error, the user

is in the service

menu.

A suitably pan must be

placed on the relevant

cooking zone

.

The cooking will be

con

fi

gured if a

fl

a-

shing "C" is shown.

After a successful

con

fi

guration the

relevant display

shows "-". If "-" is not

displayed check the

possible causes of

the E/5

User is in the

service menu, no

error

Wait for the symbol "-"

or abort the con

fi

gu-

ration activities by

pressing the select key

and the "C" will not

fl

ash

anymore.

.

A

fl

ashing "E" on

each cooking zone

indicates that all

con

fi

gs will be

deleted

User is in service

menu, no error

Manual con

fi

guration

.

Temperature limits

are exceeded

Pt or glass tempe-

rature is too high

NTC -> electronic

temperature too

high

System must cool down

.

Unsuitable pot, e.g.

loss of the magnetic

characteristics be-

cause of temperatu-

re in the bottom

On the module

a pot creates

an improper

operatioing point

which can destroy

devices, e.g IGBTs.

1. The error is automa-

tically cancelled after 8

s and the cooking zone

can be used again. In

case of further upco-

ming errors the pot has

to be replaced.

2. The module has to

be changed if the error

comes without a pot on

the cooking zone.

.

Uncon

fi

gured in-

duction module (all

induction module

answer to UI, but

any element is rela-

ted to the e

ff

ected

cooking zone.)

induction module

is not con

fi

gured

Delete the hob con

fi

gu-

ration and activate the

manual con

fi

guration.

Start the UI service

menu to con

fi

gure the

induction module if the

listed points are not

successful replace the

module.

.

No communication

between UI and

induction module

No power supply

of induction

module.

Bad cabling or

defect

Check power and LIN

connections. If con-

nection is OK, replace

the module

.

Main power distur-

bance

1. Failure in main

power frequency

detection

2. Overvoltage

Check main power

voltage and frequency,

if ok replace the module

.

Non assignable

failure

Replace module or User

interface

.

Fan failure

Fan or control

electronic is defect

Replace the module

.

Defect ive tempe-

rature probe on

inductor

Sensor signal out

of valid range; sen-

sor or electronic is

defect

Replace the module

.

Hardware defect of

induction module

Defect hardware

device detected

by the self-check

of the module

Replace the module

.

Con

fi

guration failure 2 cooking zones

are delicated to

the same element

of the UI

Delete the actual con

fi

-

guration

manual con

fi

guration

with service menu

.

Fixed sensor value

(test function for T

probe on inductor)

Not enough tem-

perature change

(10 K) within 5 min

after switch on

the hob

System must cool down

No

functiona-

lity and no

displaying

Overvoltage on

the switch mode

power supply (no

functionality)

400 V connection

Disconnect and correct

the power line con-

nection

Note:

Not each failure can be delected automatically by the system, e.g. in case of defect of the

User interface power supply.

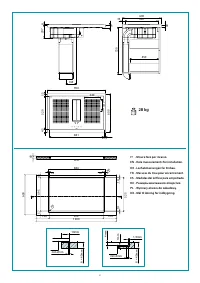

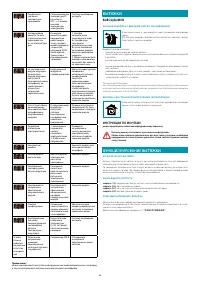

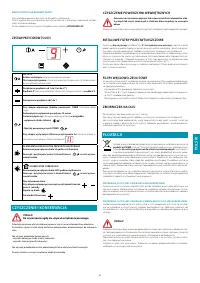

COOKER HOOD

FUMES DISCHARGE

EXTERNAL EXHAUST HOOD

(

SUCTION

)

In this version the fumes and vapours are discharged outside through

the exhaust pipe.

To this end, the hood outlet

fi

tting must be connected via a pipe, to an

external output.

The outlet pipe must have:

• a diameter not less than that of the hood

fi

tting.

• a slight slope downwards (drop) in the horizontal sections to prevent condensation from

fl

owing back into the motor.

• the minimum required number of bends.

• the minimum required length to avoid vibrations and reduce the suction performance of

the hood.

You are required to insulate the pipes if it passes through cold environments.

In the presence of motors with 800m

3

/h or higher, a check valve is present to prevent

external air

fl

owing back.

Deviation for Germany:

when the kitchen hood is used at the same time as appliances that are powered by energy other

than electricity, the negative pressure in the room must not exceed 4 Pa (4 x 10-5 bar).

HOOD WITH INTERNAL RECIRCULATION

(

FILTERING

)

In this model, the air passes through the charcoal

fi

lters (optionale) to

be puri

fi

ed and recycled in the environment.

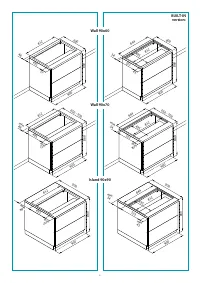

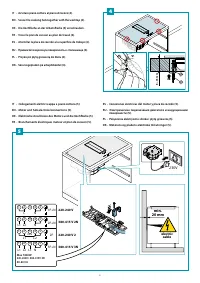

ASSEMBLY INSTRUCTIONS

only intended for quali

fi

ed personnel

The hood can be installed in various con

fi

gurations.

The generic assembly steps apply to all installations; for each case, follow

the speci

fi

c steps provided for the required installation.

Характеристики

Остались вопросы?Не нашли свой ответ в руководстве или возникли другие проблемы? Задайте свой вопрос в форме ниже с подробным описанием вашей ситуации, чтобы другие люди и специалисты смогли дать на него ответ. Если вы знаете как решить проблему другого человека, пожалуйста, подскажите ему :)