Бензопилы GRAPHITE 89G940 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

16

•

I

nstall the guide bar (

20

) (slide it behind the clutch) onto guiding

screws (

c

) and push towards driving chain wheel (

fig. B

).

•

Put the chain (

21

) onto guide bar chain wheel (

22

) from below.

•

M

ove the guide bar (

20

) away from the driving chain wheel, so

chain guiding links are placed in the guide bar groove.

•

Ensure the pin (

a

) of the chain tension adjustment screw (

8

) is in

the middle of the lower hole (

b

) of the guide bar (

20

), adjust when

necessary (

fig. B

).

•

Place the casing (

10

) in its place and fix by slightly tightening

guide bar fixing nuts (

7

).

•

Strain the chain appropriately using the chain tension adjustment

screw (

8

). Chain tension is appropriate when the chain can be

lifted by 3 to 4 mm in the middle of the guide bar in horizontal

position.

•

Firmly tighten guide bar fixing screws (

7

) while holding the guide

bar tip.

Prior to guide bar and chain installation ensure that position of

chain cutting blades is appropriate (correct position of the chain

on the guide bar is shown on the tip of the guide bar). Always wear

protective gloves during checks and installation of the chain to

prevent cuts from sharp edges of the chain.

New chain requires start-up period, which lasts approximately 5

minutes. Chain lubrication is very important in this phase. Check

chain tension after start-up period and readjust if necessary.

Check and adjust the chain tension frequently. Too loose chain

can easily slide off the guide bar, quickly wear out or quickly wear

out the guide bar.

FILLING SAW TANK WITH OIL

Oil tank in new chain saw is empty. Fill the tank with oil prior to first

use.

•

Unscrew oil filler plug (

18

).

•

Pour in maximally 260 ml of oil (be careful to avoid contamination

of oil during filling of the tank).

•

Screw oil filler plug (

18

).

Do not use oil that has been already used or regenerated, as this

may damage the oil pump.

Use SAE 10W/30 oil for the whole year,

or SAE 30W/40 in summer and SAE 20W/30 in winter.

FILLING THE FUEL TANK

When filling the fuel, follow these rules:

• Engine must not work,

• You must not spill the fuel.

A

ccordingly to the below table, mix petrol (lead-free with octane

number 95) with good quality engine oil for two stroke engines.

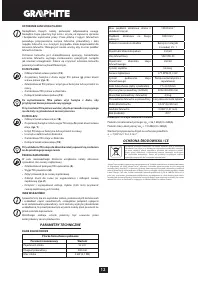

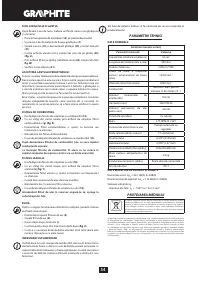

RECOMMENDED FUEL BLEND RATIO

Working conditions

Petrol : oil

First 20 hours of operation

20 : 1

A

fter 20 hours of operation

25 : 1

•

Unscrew fuel filler plug (

15

).

•

Pour in previously prepared fuel blend (max. 550 ml).

•

Screw fuel filler plug (

15

).

Most problems with combustion engines result directly or

indirectly from fuel used. You must not use oil designed for four-

stroke engines to prepare fuel blend.

OPERATION / SETTINGS

STARTING THE ENGINE

Hold the chain saw with both hands during operation.

•

Check level in the fuel tank and the oil tank.

•

Ensure the brake lever (

6

) is in the switched on position (moved

to the front).

•

When engine is cold, pull out choke cable (

2

).

•

Set the ignition switch (

14

) to switched on position (

fig. C

).

•

Place the saw on stable ground.

•

While holding the saw pressed against ground, pull the starter line

(

13

). First slowly so to hear the clutch gears, then pull it strongly

(

fig. D

).

•

A

fter starting the saw, press the throttle lever lock (

1

) and

throttle level (

11

) slightly (choke cable will move automatically to

switched off position).

•

A

llow the engine to heat up with throttle lever (

11

) slightly

pressed.

•

M

ove the brake lever (

6

) to switched off position (to the back).

•

M

ake a cut.

I

n case the engine does not start at the first try, pull out the choke

cable (

2

) halfway and pull the starter line again.

Do not start the engine while holding the saw in hands. During

start up the chain saw must rest on ground and be held firmly.

Ensure the chain is free to move without touching any object. Do

not cut any material with choke cable pulled out.

STOPPING THE ENGINE

•

Release the throttle lever (

11

) and allow the engine to run idle for

a few minutes.

•

Set the ignition switch (

14

) to STOP position.

CHECKING CHAIN LUBRICATION

Check lubrication of the chain and oil level in the tank before

starting to work. Switch on the saw and hold it above ground.

I

f you

see enlarging oil marks, the chain lubrication works well (

fig. E

).

I

f

there are no oil marks or they are very small, use oil feed adjustment

screw (

9

) to make appropriate adjustments.

I

n case the adjustment

brings no effects, clean oil outlet, upper hole of chain tension and

oilway, or contact service.

Make adjustments when the saw is switched off, observe

precaution measures and do not allow the guide bar to touch

ground. Operate the tool safely and maintain at least 20 cm

distance from ground.

Use oil feed adjustment screw (

9

) to set amount of supplied oil

accordingly to respective operating conditions.

•

MIN

position – oil flow decreases.

•

MAX

position – oil flow increases (

fig. F

).

When cutting hard and dry wood and using whole length of the

guide bar when making a cut, set the oil feed adjustment screw (

9

)

to the

MAX

position.

You can reduce amount of oil supplied by turning oil feed

adjustment screw (

9

) to

MIN

position, when cutting soft and damp

wood, or when only part of the working length of the guide bar is

used.

Oil tank should be almost empty when the fuel tank is emptied.

When filling the fuel remember about filling oil tank as well.

CHAIN LUBRICANTS

Durability of chain and guide bar depends heavily on quality of

lubricant. Use only lubricants, which are designed for chain saws.

Never use regenerated or previously used oil for chain lubrication.

CHAIN GUIDE BAR

Guide bar (

20

) is exposed to heavy wear especially in tip and bottom

part. To prevent side wear due to friction, it is recommended to turn

over the guide bar every time the chain is sharpened. Clean the

guide bar groove and oil holes on that occasion. Guide bar groove is

rectangular. Check the groove against wear. Put rule to guiding strip

and outer surface of a chain tooth.

I

f you observe distance between,

the groove is correct. Otherwise the guide bar is worn out and needs

to be replaced.

CHAIN WHEEL

Driving chain wheel is subject to especially heavy wear. Replace the

chain wheel when you observe clear signs of wear of wheel teeth.

Worn chain wheel additionally reduces durability of chain. Chain

wheel should be replaced by authorised service workshop.