Компрессоры Stanley D 211/8/24 100546056 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

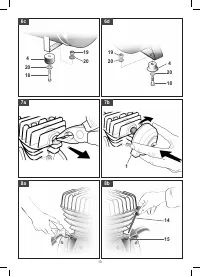

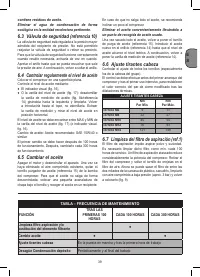

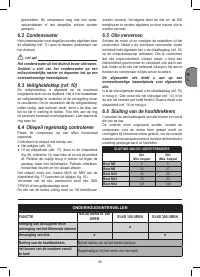

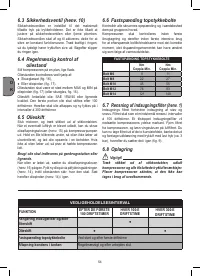

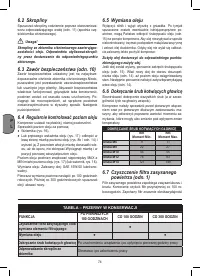

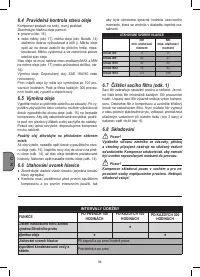

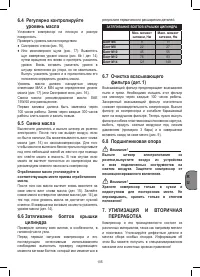

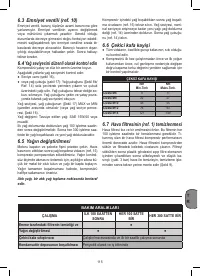

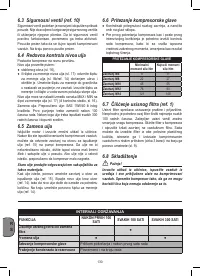

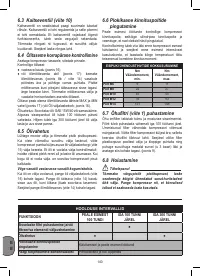

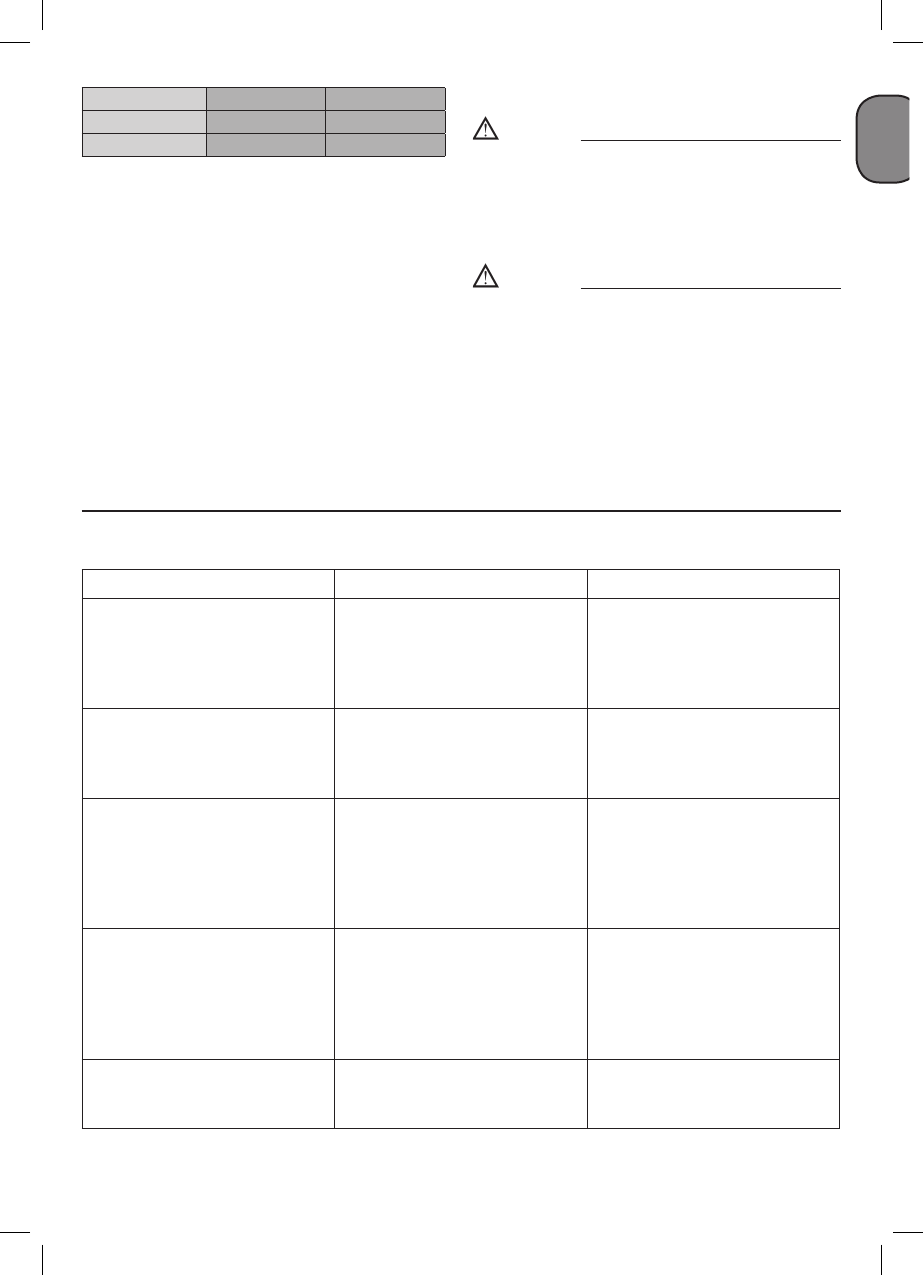

25

G

B

Screw M10

45

55

Screw M12

76

93

Screw M14

121

148

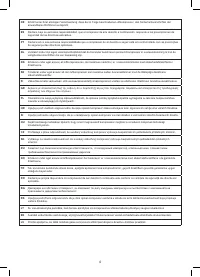

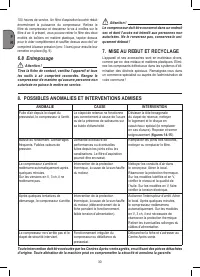

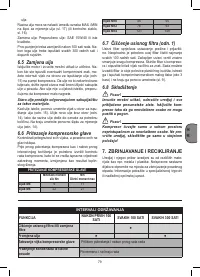

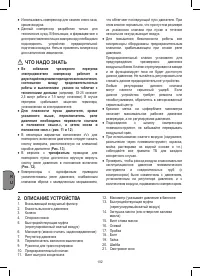

6.7 Cleaning the intake filter (ref. 1)

The intake filter prevents dust and dirt being drawn in.

It is essential to clean this filter after at least every 100

hours in service. A clogged intake filter will decrease

the compressor’s performance dramatically. Remove

the filter from the compressor and undo the thumb

screw on the air filter. You can then remove the filter

from the two halves of the plastic housing, tap it to

remove the dirt, blast it down with low-pressure com-

pressed air (approx. 3 bar) and re-insert it (Fig. 9).

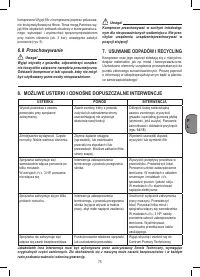

6.8 Storage

Warning!

Pull the mains plug out of the socket and ventilate

the appliance and all connected pneumatic tools.

Switch off the compressor and make sure that it is

secured in such a way that it cannot be started up

again by any unauthorized person.

Warning!

Store the compressor only in a dry location which

is not accessible to unauthorized persons. Always

store upright, never tilted!

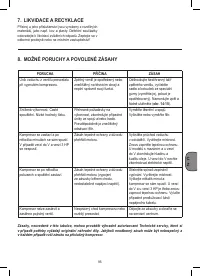

7. DISPOSAL AND RECYCLING

The unit and its accessories are made of various types

of material, such as metal and plastic. Defective com-

ponents must be disposed of as special waste. Ask

your dealer or your local council.

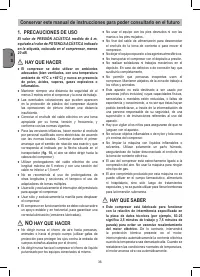

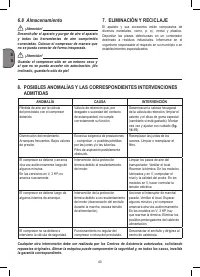

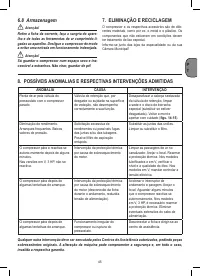

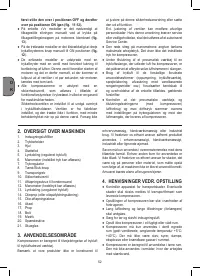

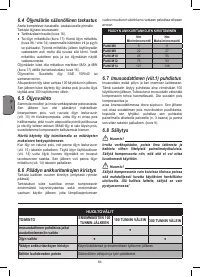

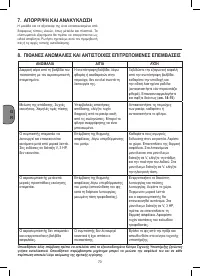

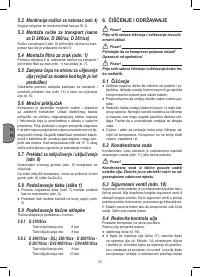

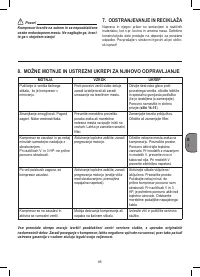

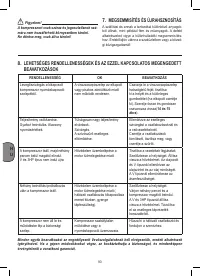

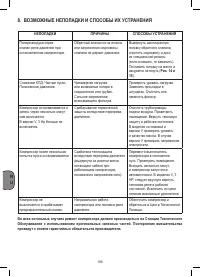

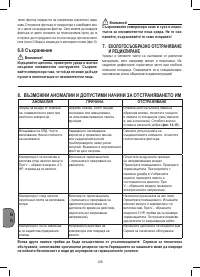

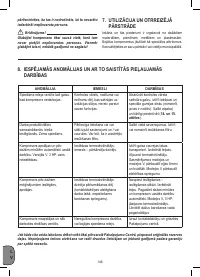

8. POSSIBLE FAULTS AND RELATED PERMITTED REMEDIES

FAULT

CAUSE

REMEDY

Leakage of air from the valve

of the pressure switch with the

compressor off.

Check valve that, due to wear or

dirt on the seal, does not perform

its function correctly.

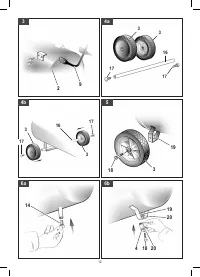

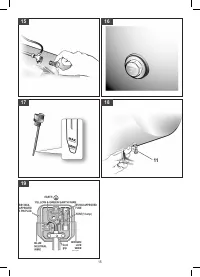

Unscrew the hexagonal head of

the check valve, clean the valve

seat and the special rubber disk

(replace if worn). Reassemble and

tighten carefully (figures

14-15

).

Reduction of performance.

Frequent start-up. Low pressure

values.

Excessive performance request,

check for any leaks from the

couplings and/or pipes. Intake filter

may be clogged.

Replace the seals of the fitting,

clean or replace the filter.

The compressor stops and restarts

automatically after a few minutes.

In the V, 3 HP versions, it is does

not start.

Tripping of the thermal cutout due

to overheating of the motor.

Clean the air ducts in the

conveyor. Ventilate the work

area. Reset the thermal cutout.

On lubricated and V type models,

check oil level and quality. On V

models, have the voltage checked.

After a few attempts to restart, the

compressor stops.

Tripping of the thermal cutout

due to overheating of the motor

(removal of the plug with the

compressor running, low power

voltage).

Activate the on/off switch. Ventilate

the work area. Wait a few minutes.

The compressor will restart

independently. On V, 3 HP models,

reset the thermal cutout. Remove

any power cable extensions.

The compressor does not stop and

the safety valve is tripped.

Irregular functioning of the

compressor or breakage of the

pressure switch.

Remove the plug and contact the

Service Center.

Any other type of operation must be carried out by authorized Service Centers, requesting original parts.

Tampering with the machine may impair its safety and in any case make the warranty null and void.