Компрессоры Stanley D 211/8/24 100546056 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

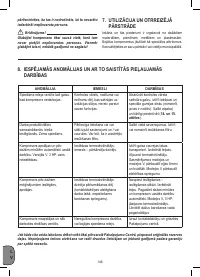

23

G

B

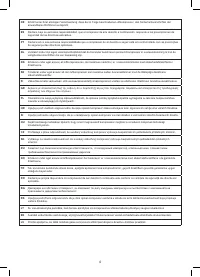

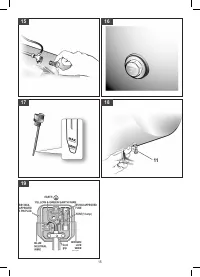

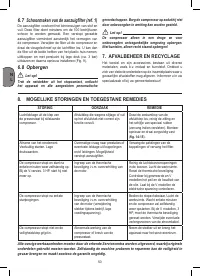

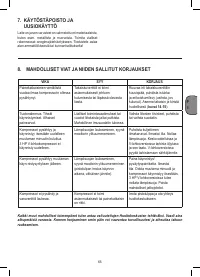

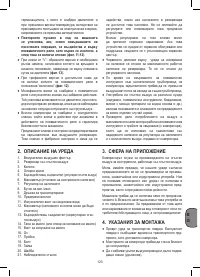

5.2 Fitting the supporting foot (ref. 4)

Fit the supplied rubber stopper as shown in Fig. 6.

5.3 Fitting the transport handle (only

for D 240/xx, D 260/xx, D 261/xx)

Screw the transport handle (ref. 9) to the compressor

as shown in Fig. 3.

5.4 Fitting the air filter (ref. 1)

Remove the transportation stop with a screwdriver or

similar and screw the air filter (ref. 1) securely to the

equipment (Fig. 7).

5.5 Replacing the oil sealing plug

(for models envisaging this)

Remove the transportation cover from the oil filler

opening with a screwdriver and insert the supplied oil

dipstick (ref. 14) into the oil filler opening (Fig. 8).

5.6 Voltage

The compressor is equipped with a mains cable with earth

wire. Insert the plug of the electric cable in a socket of suit

-

able shape, voltage and frequency complying with current

regulations. Before you use the machine, make sure that

the mains voltage complies with the specifications on the

rating plate. Long supply cables, extensions, cable reels

etc. cause a drop in voltage and can impede motor start-

up. In the case of low temperatures below +5°C, motor

start-up is jeopardized as a result of stiffness.

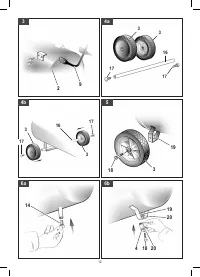

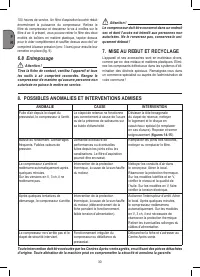

5.6.1 Connection of the mains plug (electrical

information for the BS plug)

Important!

The wires in the mains lead fitted to this product are

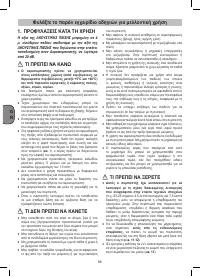

coloured in accordance with the code shown in fig. 19.

● The 3 pin plug must comply to BS1363/A.

● Fuse must comply to BS1362.

If for any reason the 13 amp plug fitted to this product

requires replacement it must be wired in accordance

with the following instruction:

Do not connect the brown (live) or blue (neutral)

to the earth pin marked ‘E’ on the 3 pin plug.

Connect the Blue wire to the terminal marked Neutral

(N). Connect the Brown wire to the terminal marked Live

(L). Connect the Yellow & Green wire to the terminal

marked Earth (E). Ensure that the outer insulation is

gripped by the cord grip and that the wires are not

trapped when replacing the plug cover. The mains lead

on this product is fitted with a 13 amp (BS1363/A) plug.

A 13 amp (BS1362) fuse must be fitted in the plug.

If in doubt consult a qualified electrician

There are no user serviceable parts inside this product

except those referred to in the manual. Always refer

servicing to qualified service personnel. Never remove

any part of the casing unless qualified to do so; this unit

contains dangerous voltages.

Warning!

For your protection if this product is to be used outdoors

it should not be exposed to rain or used in damp

locations. Do not place the product on damp surfaces,

use a workbench if available. For added protection use

a suitable residual current device (R.C.D.) at the socket

outlet.

Note:

If the mains cable requires replacing it must be

replaced with an identical one and fitted by a

qualified person.

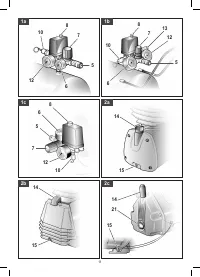

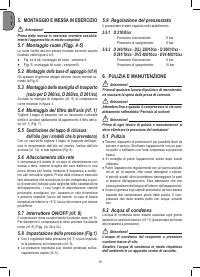

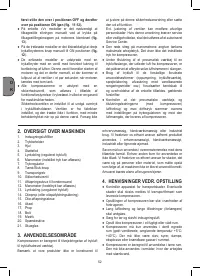

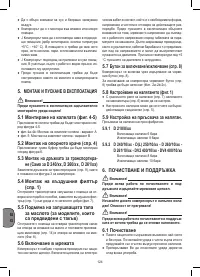

5.7 On/Off switch (8)

To switch on the compressor, pull out the red knob (ref. 8).

To switch off the compressor, press the red knob (8) in

again (Fig. 2a, 2b & 2c).

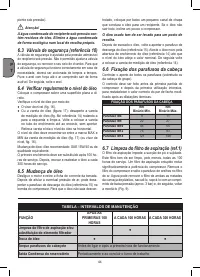

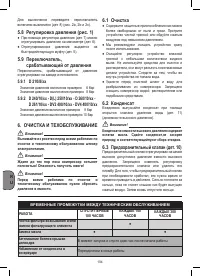

5.8 Adjusting the pressure (Fig. 1)

●

You can adjust the pressure on the pressure gauge

(ref. 6) using the pressure regulator (ref. 7).

●

The set pressure can be taken from the quicklock

coupling (ref. 5).

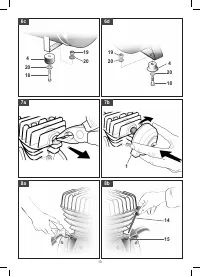

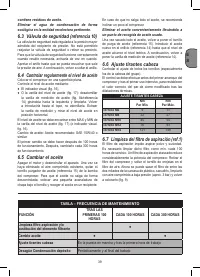

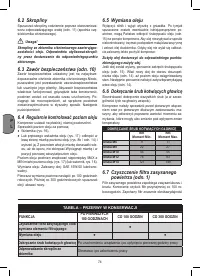

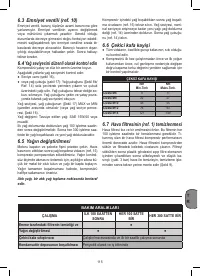

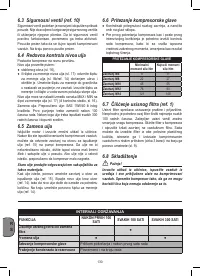

5.9 Setting the pressure switch

The pressure switch is set at the factory.

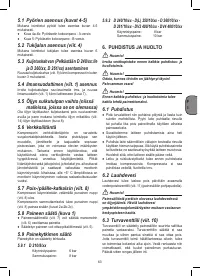

5.9.1 D 210/8/xx

Switch-on pressure

:

6 bar

Switch-off pressure

:

8 bar

5.9.2 D 240/10/xx - D(L) 250/10/xx - D 260/10/xx -

D 261/10/xx - DV2 400/10/xx - DV4 400/10/xx

Switch-on pressure

:

8 bar

Switch-off pressure

:

10 bar

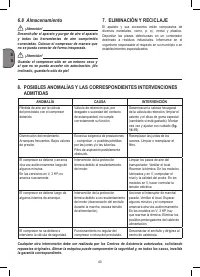

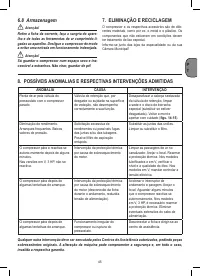

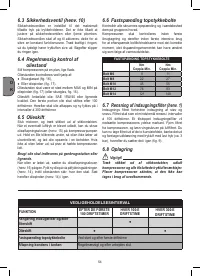

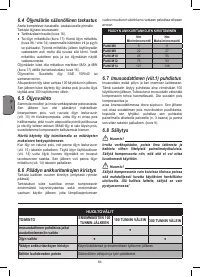

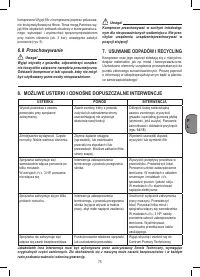

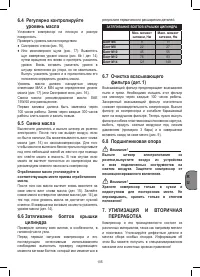

6. CLEANING AND MAINTENANCE

Warning!

Pull the power plug before doing any cleaning and

maintenance work on the appliance.

Warning!

Wait until the compressor has completely cooled

down. Risk of burns!

Warning!

Always depressurize the tank before carrying out

any cleaning and maintenance work.