Компрессоры Stanley D 211/8/24 100546056 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

24

G

B

6.1 Cleaning

●

Keep the safety devices free of dirt and dust as far

as possible. Wipe the equipment with a clean cloth

or blow it with compressed air at low pressure.

●

We recommend that you clean the appliance imme

-

diately after you use it.

●

Clean the appliance regularly with a damp cloth and

some soft soap. Do not use cleaning agents or sol

-

vents; these may be aggressive to the plastic parts

in the appliance. Ensure that no water can get into

the interior of the appliance.

●

You must disconnect the hose and any spraying tools

from the compressor before cleaning. Do not clean the

compressor with water, solvents or the like.

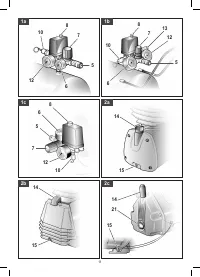

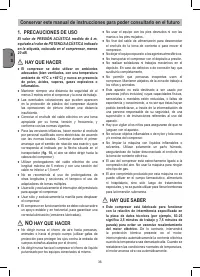

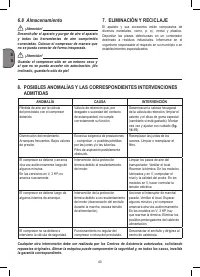

6.2 Condensation water

The condensation water must be drained off each day

by opening the drain valve (ref. 11) (on the

bottom of

the pressure vessel).

Warning!

The condensation water from the pressure vessel

will contain residual oil. Dispose of the condensa-

tion water in an environmentally compatible man-

ner at the appropriate collection point.

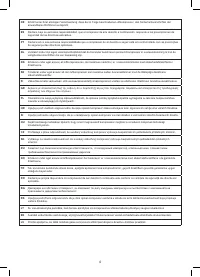

6.3 Safety valve (ref. 10)

The safety valve has been set for the highest permit

-

ted pressure of the pressure vessel. It is prohibited to

adjust the safety valve or remove its seal. Actuate the

safety valve from time to time to ensure that it works

when required. Pull the ring with sufficient force until

you can hear the compressed air being released. Then

release the ring again.

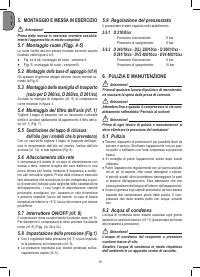

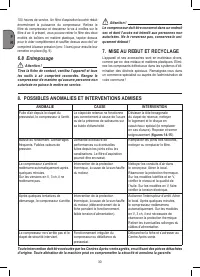

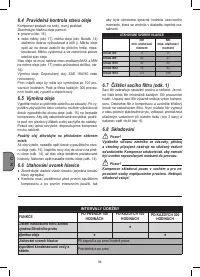

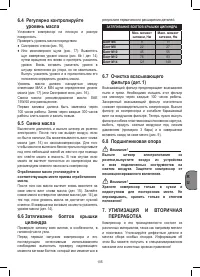

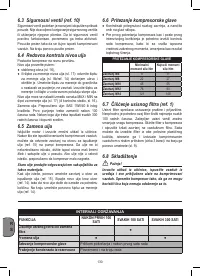

6.4 Check the oil level at regular intervals

Place the compressor on a level and straight surface.

Check the oil level by means of:

● The sight glass (fig. 16),

● Or the oil dipstick (figure 17): unscrew the oil dipstick

(Fig. 8b / reference 14) by turning it counter-clock-

wise and wipe the dipstick. Re-insert the dipstick into

the filler opening as far as it will go but do not screw

it in. Pull out the dipstick, hold it horizontally and read

off the oil level.

The oil level must be between the two marks MAX and

MIN on the oil dipstick (Fig. 17) (or oil level window,

fig. 16).

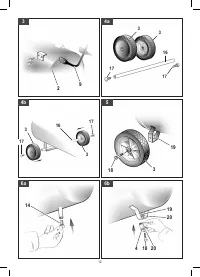

Changing the oil: Recommended oil: SAE 15W/40 or

an alternative of the same quality.

It should be refilled for the first time after 100 hours

of operation. Thereafter the oil should be drained and

refilled after every 300 hours in service.

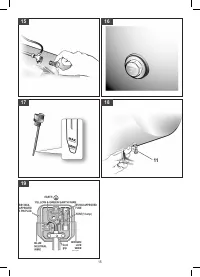

6.5 Changing the oil

Switch off the engine and pull the mains plug out of

the socket. After releasing any air pressure you can

unscrew the oil drainage screw (ref. 15) from the com-

pressor pump. To prevent the oil from running out in an

uncontrolled manner, hold a small metal chute under

the opening and collect the oil in a vessel. If the oil

does not drain out completely, we recommend tilting

the compressor slightly.

Dispose of the old oil at a drop-off point for old oil.

When the oil has drained out, re-fit the oil drainage

screw (ref. 15). Fill new oil through the oil filler opening

(ref. 14) until it comes up to the required level. Then

reinsert the oil dipstick (ref. 14).

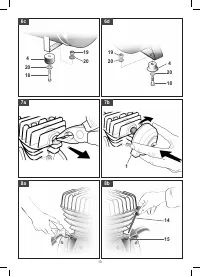

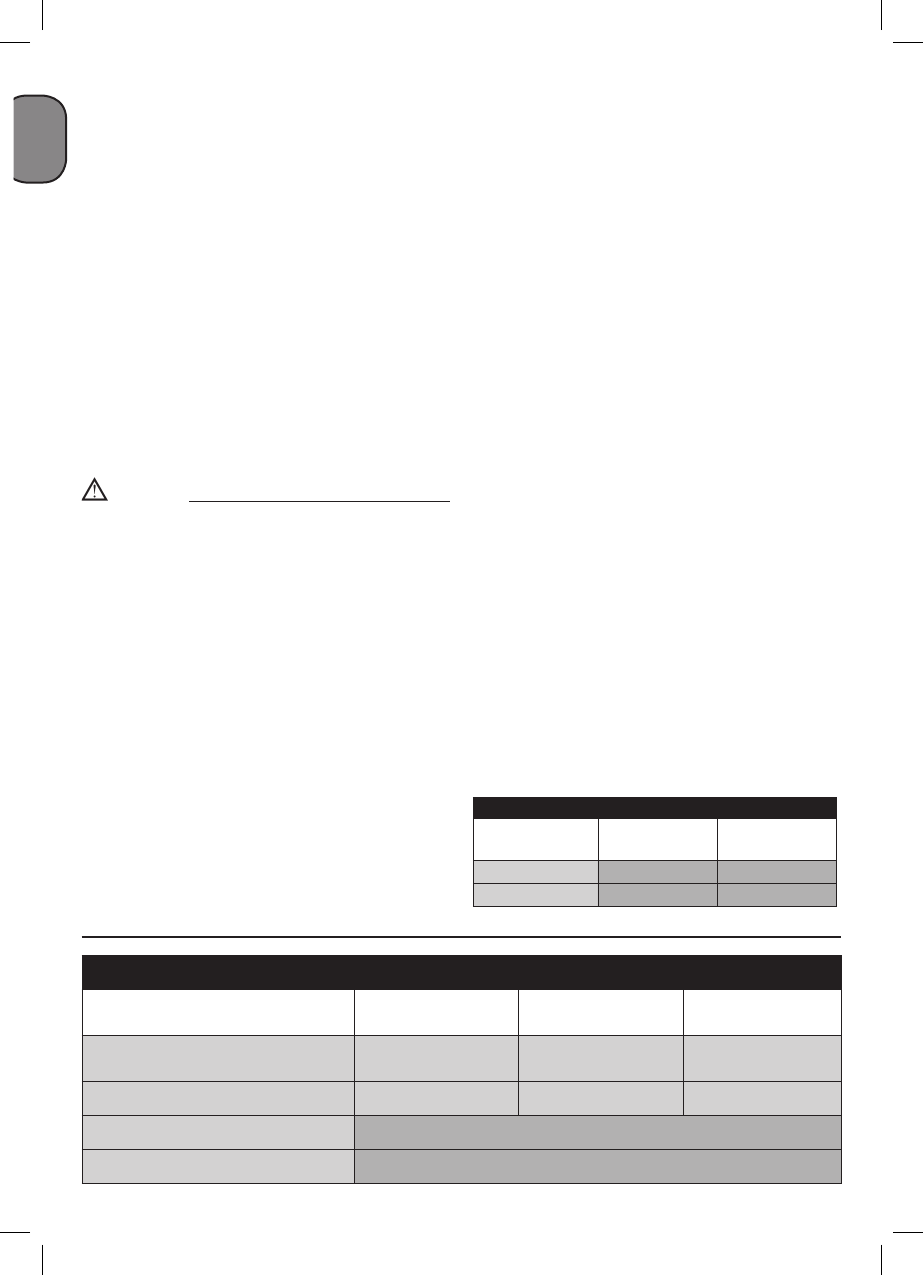

6.6 Tightening of head tension rods

● Check that all screws (in particular those of the head

of the unit) are tightly drawn up.

● The control must be performed before the first start-up

of the compressor and subsequently before the first

intensive use in order to restore the correct closing

torque value modified as a result of heat expansion.

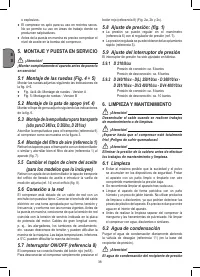

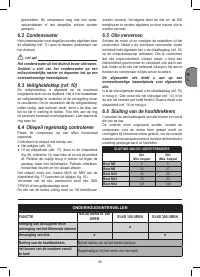

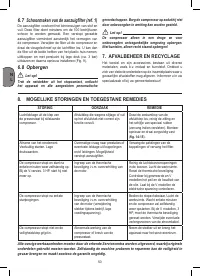

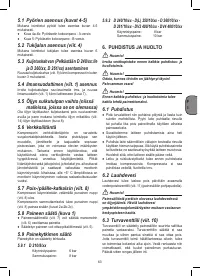

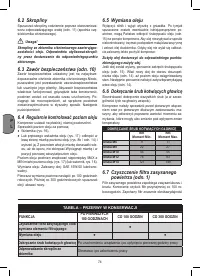

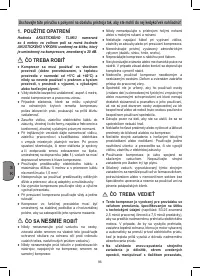

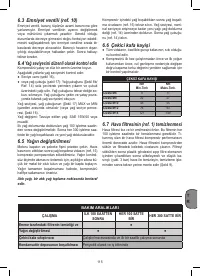

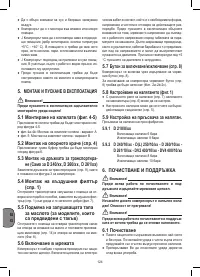

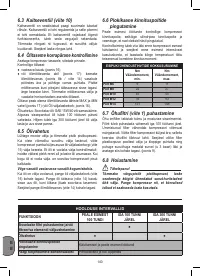

TIGHTENING OF HEAD TENSION RODS

Nm

Min. torque

Nm

Max. torque

Screw M6

9

11

Screw M8

22

27

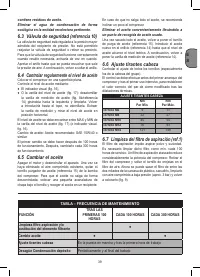

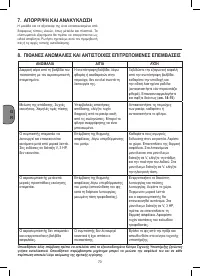

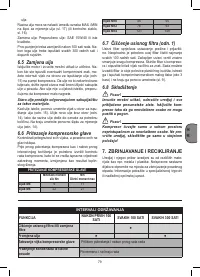

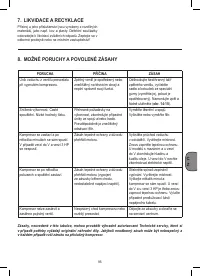

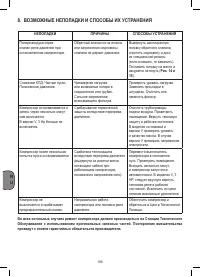

MAINTENANCE RESUMPTIVE TABLE

FUNCTION

AFTER THE FIRST

100 HOURS

EVERY 100 HOURS EVERY 300 HOURS

Cleaning of intake filter and/or

substitution of filtering element

●

Change of oil

●

●

Tightening of head tension rods

At start-up and after the first hour of work

Draining tank condensate

Periodically and at the end of work