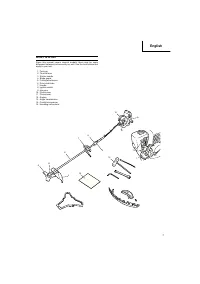

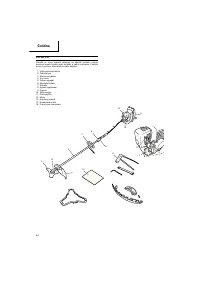

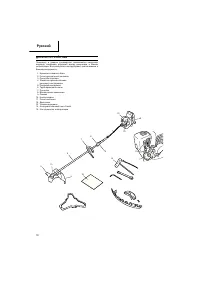

Триммеры Hitachi CG40EAF - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

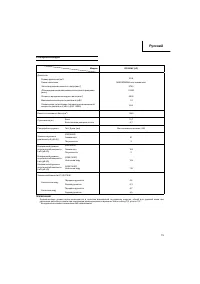

11

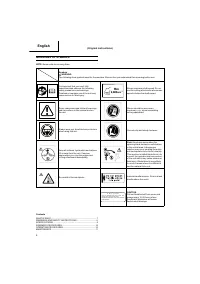

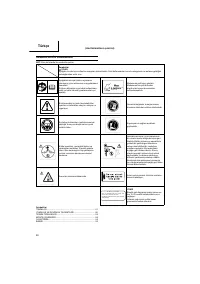

English

Before fueling, clean the tank cap area carefully, to ensure that

no dir t falls into the tank. Make sure that the fuel is well mixed by

shaking the container, before fueling.

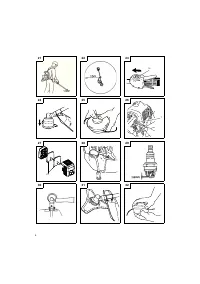

Starting

CAUTION

Before star ting, make sure the cutting attachment does not

touch any thing.

1. Slide ignition switch (18) to RUN position. (

Fig.

17

)

* Push priming bulb (19) several times so that fuel

fl

ows through

return pipe. (

Fig.

18

)

2. Set choke lever (20) to START position (A). (

Fig.

19

)

3. Pull recoil star ter briskly, taking care to keep the handle in your

grasp and not allowing it to snap back. (

Fig.

20

)

4. When you hear the engine want to star t, return choke lever to

RUN position (B). Then pull recoil star ter briskly again.

NOTE

If engine does not star t, repeat procedures from 2 to 4.

5. After star ting engine, allow the engine about 2– 3 minutes to

warm up before subjecting it to any load.

Cutting

(

Fig.

21,

22

)

○

When cutting, operate engine at over 6500 min

-1

. Extended

time of use at low rpm may wear out the clutch prematurely.

○

Cut grass from right to left.

○

When working on a slope, the blade should allow the contour

from top to bottom, with the operator looking down to the left.

○

Blade thrust may occur when the spinning blade contacts a

solid object in the critical area.

A dangerous reaction may occur causing the entire unit and

operator to be thrust violently. This reaction is called blade

thrust. As a result, the operator may lose control of the unit

which may cause serious or fatal injur y. Blade thrust is more

likely to occur in areas where it is di

ffi

cult to see the material to

be cut.

○

The blade turns counter-clockwise, therefore, be advised to

operate the unit from right to left for e

ffi

cient cutting. Keep

onlookers out of working area at least 15 m.

WARNING

If cutting attachment should strike against stones or other

debris, stop the engine and make sure that the attachment

and related par ts are undamaged. When grass or vines wrap

around attachment, stop engine and attachment and remove

them.

Stopping

(

Fig.

23

)

Decrease engine speed and run at an idle for a few minutes, then

turn o

ff

ignition switch (18).

WARNING

A cutting attachment can injure while it continues to spin after

the engine is stopped or power control is released. When the

unit is turned o

ff

, make sure the cutting attachment has stopped

before the unit is set down.

How

to

use

nylon

head

When cutting, operate engine at over 6500 min

-1

. Extended use at

low rpm may wear out the clutch prematurely.

This product is designed so that it will stop cutting when the nylon

line becomes 16 cm or longer.

WARNING

A cutting attachment can injure while it continues to spin after the

engine is stopped or power control is released. When the unit is

turned o

ff

, make sure the cutting attachment has stopped before

the unit is set down.

Set the engine speed as low as possible and tap the Head on the

ground. (

Fig.

24

) Also, you can extend nylon line with hands but the

engine must be completely stopped. (

Fig.

25

)

Adjust nylon line to proper length 11-14 cm before each operation.

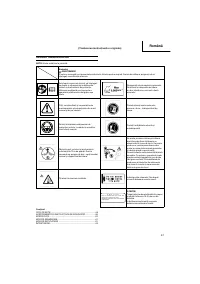

MAINTENANCE

MAINTENANCE, REPL ACEMENT OR REPAIR OF THE EMISSION

CONTROL DEVICES AND SYSTEMS MAY BE PERFORMED

BY ANY NON-ROAD ENGINE REPAIR ESTABLISHMENT OR

INDIVIDUAL.

Carburetor

adjustment

(

Fig.

26

)

WARNING

○

The cutting attachment may be spinning during carburetor

adjustments.

○

Never star t the engine without the complete clutch cover and

tube assembled! Other wise the clutch can come loose and

cause personal injuries.

In the carburetor, fuel is mixed with air. When the engine is test

run at the factor y, the carburetor is basically adjusted. A fur ther

adjustment may be required, according to climate and altitude. The

carburetor has one adjustment possibility:

T

=

Idle

speed

adjustment

screw.

Idle

speed

adjustment

(

T

)

Check that the air

fi

lter is clean. When the idle speed is correct, the

cutting attachment will not rotate. If adjustment is required, close

(clockwise) the T-screw, with the engine running, until the cutting

attachment star ts to rotate. Open (counter-clockwise) the screw

until the cutting attachment stops. You have reached the correct idle

speed when the engine runs smoothly in all positions well below the

rpm when the cutting attachment star ts to rotate.

If the cutting attachment still rotates after idle speed adjustment,

contact your Hitachi dealer.

NOTE

Standard Idle rpm is 2500 – 3000 min

-1

.

WARNING

When the engine is idling the cutting attachment must under no

circumstances rotate.

Air

fi

lter

(

Fig.

27

)

The air

fi

lter must be cleaned from dust and dir t in order to avoid:

○

Carburetor

malfunctions

○

Star ting

problems

○

Engine power reduction

○

Unnecessar y wear on the engine par ts

○

Abnormal fuel consumption

Clean the air

fi

lter daily or more often if working in exceptionally

dusty areas.

Cleaning

the

air

fi

lter

Remove the air

fi

lter cover and the

fi

lter (21). Rinse it in warm soap

suds. Check that the

fi

lter is dr y before reassembly. An air

fi

lter

that has been used for some time cannot be cleaned completely.

Therefore, it must regularly be replaced with a new one. A damaged

fi

lter must always be replaced.

Fuel

fi

lter

(

Fig.

28

)

Drain all fuel from fuel tank and pull fuel

fi

lter line from tank. Pull

fi

lter element out of holder assembly and rinse element in warm

water with detergent.

Rinse thoroughly until all traces of detergent are eliminated.

Squeeze, do not wring, away excess water and allow element to air

dr y.

NOTE

If element is hard due to excessive dir t buildup, replace it.

Spark

plug

(

Fig.

29

)

The spark plug condition is in

fl

uenced by:

○

An incorrect carburetor setting

○

Wrong fuel mixture (too much oil in the gasoline)

○

A dir ty air

fi

lter

○

Hard running conditions (such as cold weather)

000Book̲CG40EAF̲EE.indb 11

000Book̲CG40EAF̲EE.indb 11

2010/04/19 18:51:41

2010/04/19 18:51:41