Пилы торцовочные Bosch 0.601.B19.200 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

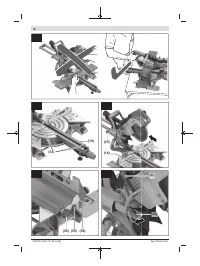

– Swivel the tool arm by the handle

(9)

into the required

position.

– Turn the adjusting screw

(4)

until the end of the screw

touches the depth stop

(32)

.

– Slowly guide the tool arm upwards.

Special workpieces

When sawing curved or round workpieces, these must be es-

pecially secured against slipping. At the cutting line, there

should be no gap between the workpiece, fence and saw

table.

If necessary, you will need to manufacture special fixtures.

Checking and adjusting the basic settings

To ensure precise cuts, the basic settings of the power tool

must be checked and adjusted as necessary after intensive

use.

Experience and suitable special tools are required for this.

A Bosch after-sales service point will handle this work

quickly and reliably.

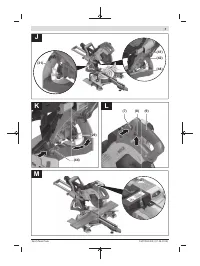

Adjusting the laser

Note:

To test the laser function, the power tool must be con-

nected to the power supply.

u

While adjusting the laser (e.g. when moving the tool

arm), never activate the on/off switch.

Accidental

starting of the power tool can lead to injuries.

– Bring the power tool into the work position.

– Turn the saw table

(16)

to the 0° detent

(25)

. The lever

(22)

must be felt to engage in the detent.

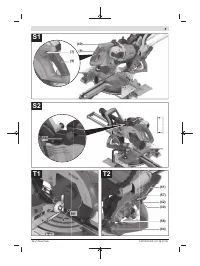

Checking (see figure S1)

– Draw a straight cutting line on the workpiece.

– Slowly guide the tool arm downwards using the handle

(9)

.

– Align the workpiece in such a manner that the teeth of the

saw blade are in alignment with the cutting line.

– Hold the workpiece in this position and slowly guide the

tool arm upward.

– Clamp the workpiece.

– Turn on the laser beam using the switch

(40)

.

The laser beam must be flush with the cutting line on the

workpiece along its entire length, even if the tool arm is

guided downwards.

Setting (see figure S2)

– Turn the set screw

(56)

with a suitable screwdriver until

the laser beam is parallel to the entire length of the cut-

ting line on the workpiece.

One rotation in an anticlockwise direction moves the laser

beam from left to right; one rotation in a clockwise direction

moves the laser beam from right to left.

Setting standard 0° bevel angles

– Bring the power tool into the work position.

– Turn the saw table

(16)

to the 0° detent

(25)

. The lever

(22)

must be felt to engage in the detent.

Checking (see figure T1)

– Set an angle gauge to 90° and place it on the saw table

(16)

.

The leg of the angle gauge must be flush with the saw blade

(12)

along its entire length.

Setting (see figure T2)

– Loosen the clamping lever

(41)

.

– Slide the stop

(44)

all the way back.

– Loosen the lock nut of the stop screw

(58)

using a con-

ventional ring spanner or open-end spanner (10 mm).

– Twist the stop screw as far in or out as needed until the

leg of the angle gauge is flush with the saw blade over the

entire length.

– Retighten the clamping lever

(41)

.

– Then retighten the lock nut of the stop screw

(58)

.

If the angle indicator

(31)

is not aligned with the 0° mark on

the scale

(30)

following adjustment, loosen the screw

(57)

using a commercially available cross-headed screwdriver

and align the angle indicator along the 0° mark.

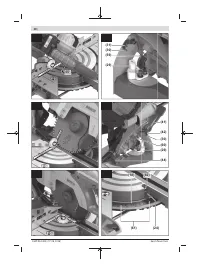

Setting standard 45° bevel angles (left)

– Bring the power tool into the work position.

– Turn the saw table

(16)

to the 0° detent

(25)

. The lever

(22)

must be felt to engage in the detent.

– Remove the left-hand adjustable fence

(15)

– Turn the left-hand stop

(29)

until the standard 45° bevel

angle engages at the arrow mark.

– Loosen the clamping lever

(41)

.

– Swivel the tool arm by the handle

(9)

to the left until the

stop screw

(59)

rests on the stop

(29)

.

Checking (see figure U1)

– Set an angle gauge to 45° and place it on the saw table

(16)

.

The leg of the angle gauge must be flush with the saw blade

(12)

along its entire length.

Setting (see figure U2)

– Loosen the lock nut of the stop screw

(59)

using a con-

ventional ring spanner or open-end spanner (10 mm).

– Twist the stop screw as far in or out as needed until the

leg of the angle gauge is flush with the saw blade over the

entire length.

– Retighten the clamping lever

(41)

.

– Then retighten the lock nut of the stop screw

(59)

.

If the angle indicators

(42)

and

(31)

are not in line with the

45° marks on the scale

(30)

following adjustment, first

check the 0° setting for the bevel angle and the angle indicat-

ors once more. Then repeat the adjustment of the 45° bevel

angle.

Setting standard 45° bevel angles (right)

– Bring the power tool into the work position.

– Turn the saw table

(16)

to the 0° detent

(25)

. The lever

(22)

must be felt to engage in the detent.

– Remove the right-hand adjustable fence

(15)

English |

35

Bosch Power Tools

1 609 92A 3UK | (07.08.2018)

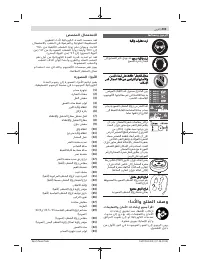

Содержание

- 232 Сервис

- 233 Символы; Символы и их значение

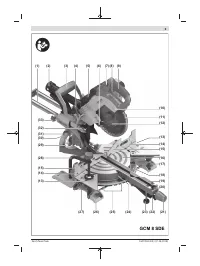

- 234 Описание продукта и услуг; Применение по назначению

- 235 Технические данные; Панельная пила

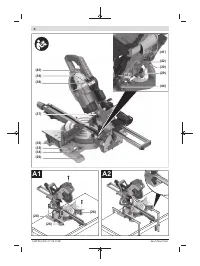

- 236 Данные о шуме; Используйте средства защиты органов слуха!; Сборка; Комплект поставки; Монтаж на верстаке производства Bosch

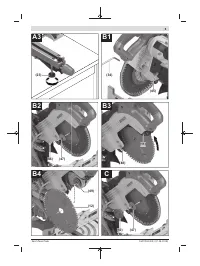

- 237 Удаление пыли и стружки; Избегайте скопления пыли на рабочем месте.; Замена пильного диска; Монтаж с помощью винта с внутренним

- 238 Работа с инструментом; Подготовка эксплуатации; Смещение упорной планки

- 239 Настройка горизонтального угла распила; слева; Настройка вертикального угла распила

- 240 Включение электроинструмента

- 241 Пиление; Установка числа оборотов; Основные настройки – контроль и коррекция

- 243 Техобслуживание и сервис; Техобслуживание и очистка; мер

- 244 Утилизация; Українська; Вказівки з техніки безпеки; ДЖЕННЯ

Характеристики

Остались вопросы?Не нашли свой ответ в руководстве или возникли другие проблемы? Задайте свой вопрос в форме ниже с подробным описанием вашей ситуации, чтобы другие люди и специалисты смогли дать на него ответ. Если вы знаете как решить проблему другого человека, пожалуйста, подскажите ему :)