Электропилы Bosch GTS 10 XC - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

English |

39

Bosch Power Tools

1 619 929 K16 | (29.8.11)

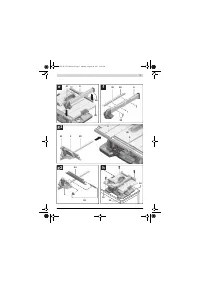

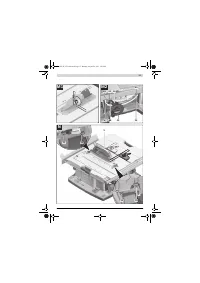

– Turn the saw blade until the marked tooth projects above

the right side of the insert plate.

– Move the angle gauge alongside the guide groove to the

marked tooth.

– Measure the clearance between the saw blade and guide

groove again.

Both clearances measured must be identical.

Adjusting:

– Loosen Allen screws

70

at the front below the saw table

and Allen screws

71

at the rear below the saw table with

the supplied Allen key

37

.

– Carefully move the saw blade until it is parallel to guide

groove

9

.

– Retighten all screws

70

and

71

again.

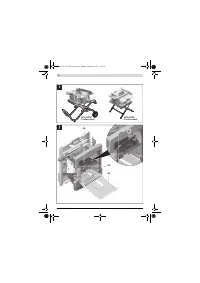

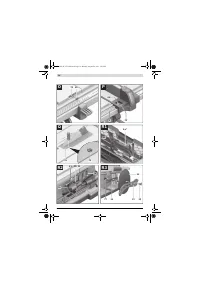

Adjusting the Saw Table’s Clearance Indicator

(see figure O)

– Position the parallel guide on the right side of the saw

blade.

Move the parallel guide until the mark in the lens

64

indi-

cates 33 cm on the bottom scale.

To lock the parallel guide, press clamping handle

47

down

again.

– Completely pull clamping handle

18

upward and pull the

table width enlargement

11

outward to the stop.

Checking:

On the upper scale

1

, clearance indicator

65

must indicate

the identical value as the mark in lens

64

on the bottom scale

1

.

Adjusting:

– Loosen screw

72

with a Phillips screwdriver and align

clearance indicator

65

alongside the 33 cm mark of the up-

per scale

1

.

Adjusting the Lens of the Parallel Guide (see figure P)

– Bring the power tool into the working position.

– Tilt the blade guard

5.x

toward the rear to the stop.

– Move parallel guide

8

from the right until it touches the saw

blade.

Checking:

The mark of lens

64

must be in a line with the 0 ° mark of scale

1

.

Adjusting:

– Loosen screw

73

using a Phillips screwdriver and align the

clearance indicator alongside the 0 ° mark.

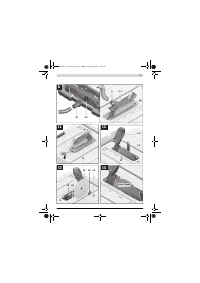

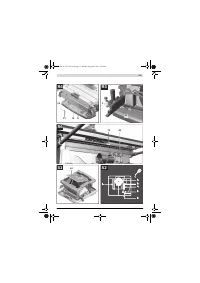

Adjusting the Level of the Insert Plate (see figure Q)

Checking:

The front side of the insert plate

31

must be flush with or

somewhat lower than the saw table; the rear side must be

flush with or somewhat above the saw table.

Adjusting:

– Adjust the correct level of the four adjusting screws

74

with a suitable slotted screwdriver.

Adjusting the Tension Force of the Parallel Guide

The tensioning force of the parallel guide

8

can decrease after

frequent usage.

– Tighten the adjustment screw

81

until the parallel guide

can be firmly affixed on the saw table again.

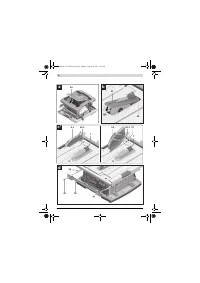

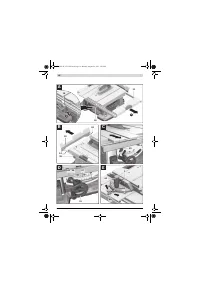

Storage and Transport

Storing Product Features (see figures R1 – R6)

For storage purposes, certain product features can be se-

curely fastened to the power tool.

– Loosen auxiliary parallel guide

49

from parallel guide

8

.

– Attach all loose tool parts to their storage locations on the

housing. (see Table)

Carrying the Power Tool

Before transporting the power tool, the following steps must

be carried out:

– Bring the machine into the transport position.

(see “Transport Position”, page 36)

– Remove all accessories that cannot be mounted firmly to

the power tool.

If possible, place unused saw blades in an enclosed con-

tainer for transport.

– Slide the table width enlargement

11

completely in and

press tensioning lever

18

downward to lock it.

– Slide the table extension

10

completely in and firmly tight-

en the locking screws

38

on the guide rods

24

.

– Wind the mains cable around the cable holder

42

.

– For lifting or transport, use the carrying handles

4

.

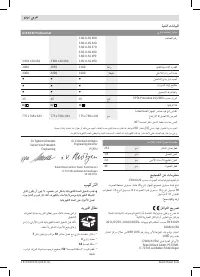

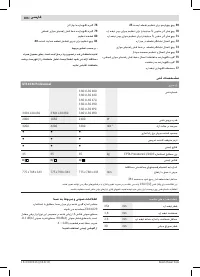

Figure Product Feature Storage Location

R1

Blade guard

5.x

Insert into the recess of fixture

22

and tighten with clamping

lever

46.1

or clamping screw

46.2

R2

“Auxiliary parallel

guide” fastening

kit

39

Clip into the holders

75

R2

Extraction

adapter

41

Insert into retaining clamp

76

R3

Unused saw

blades

Insert into saw blade storage

77

and lock the cover

14

over it

with fastening nut

12

R3

Ring spanner

15

Insert into saw blade storage

77

and lock the cover

14

over it

with fastening nut

12

R3

Push stick

13

Lock in place with fastening nut

12

R4

Allen key

37

Insert into holders

78

R4

Parallel guide

8

Insert into the storage compart-

ment for the parallel guide

36

R5

Angle stop

3

Insert into retaining clamp

23

R6

Auxiliary parallel

guide

49

Insert into the storage compart-

ment for the auxiliary parallel

guide and lock in place with the

retaining bracket

79

OBJ_BUCH-1375-002.book Page 39 Monday, August 29, 2011 5:05 PM