Электропилы Bosch GTS 10 XC - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

38

| English

1 619 929 K16 | (29.8.11)

Bosch Power Tools

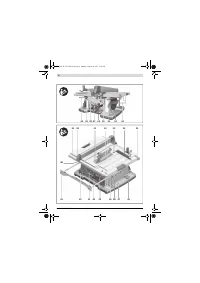

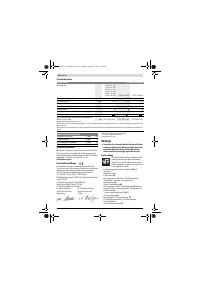

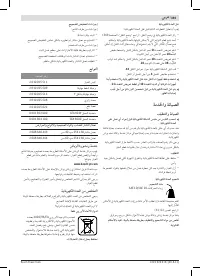

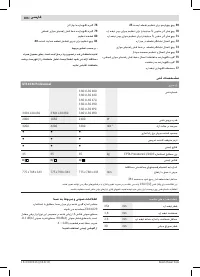

Maximum Workpiece Dimensions

Sawing

Sawing Straight Cuts

– Adjust the parallel guide

8

to the requested cutting width.

(see “Adjusting the Parallel Guide”, page 36)

– Position the workpiece on the saw table in front of the

blade guard

5.x

.

– Raise or lower the saw blade with the crank

20

so that the

upper saw teeth project approx. 5 mm above the work-

piece surface.

– Adjust the blade guard according to the workpiece height.

When sawing, the blade guard must always face lightly

against the workpiece.

– Switch on the machine.

– Saw through the workpiece applying uniform feed.

– Switch off the machine and wait until the saw blade has

come to a complete stop.

Sawing Bevel Angles

– Adjust the desired bevel angle. (see “Adjusting Bevel An-

gles”, page 36)

– Follow the worksteps in section “Sawing Straight Cuts” ac-

cordingly.

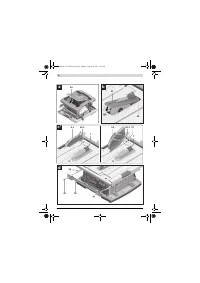

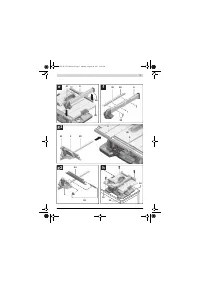

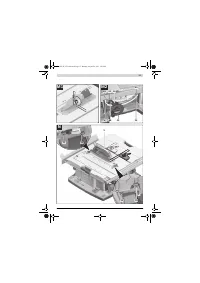

Sawing Mitre Angles (see figure L)

– Adjust the requested mitre angle (see “Adjusting Mitre An-

gles”, page 36)

– Place the workpiece against profile rail

34

.

The profile may not be on the cutting line. If so, loosen

knurled nut

53

and move the profile.

– Raise or lower the saw blade with the crank

20

so that the

upper saw teeth project approx. 5 mm above the work-

piece surface.

– Adjust the blade guard according to the workpiece height.

When sawing, the blade guard must always face lightly

against the workpiece.

– Switch on the machine.

– With one hand, press the workpiece against the profile rail

and with the other hand, slowly move the angle stop via

locking knob

62

toward the front in guide groove

9

.

– Switch off the machine and wait until the saw blade has

come to a complete stop.

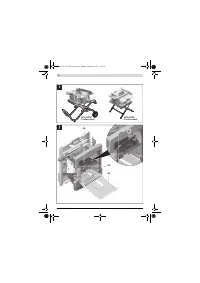

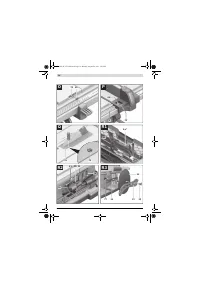

Sawing Mitre Angles with the Sliding Table Locked

– Adjust the requested mitre angle (see “Adjusting Mitre An-

gles”, page 36)

– The angle stop must move freely in the guide groove

9

(left-

ward or rightward).

For this, loosen knurled screw

51

, if required.

– Follow the worksteps in section “Sawing Straight Cuts” ac-

cordingly.

Sawing Mitre Angles with the Sliding Table

– Adjust the requested mitre angle (see “Adjusting Mitre An-

gles”, page 36)

– Completely pull clamping handle

29

for the sliding table

upward and pull the sliding table

2

toward the front.

– Position the workpiece on the saw table in front of the

blade guard

5.x

.

– Position the angle stop

3

in front of the workpiece in the

lefthand guide groove

9

. Lock this position by firmly tight-

ening the knurled screw

51

.

– Follow the worksteps in section “Sawing Straight Cuts” ac-

cordingly.

Checking and Adjusting the Basic Adjustment

To ensure precise cuts, the basic adjustment of the machine

must be checked and adjusted as necessary after intensive

use.

A certain level of experience and appropriate specialty tools

are required for this.

A Bosch after-sales service station will handle this mainte-

nance task quickly and reliably.

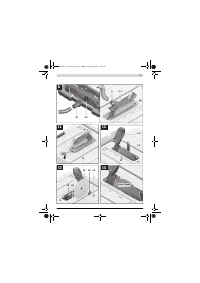

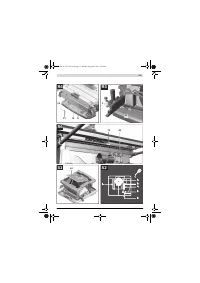

Setting the Stops for Standard 0 ° / 45 ° Bevel Angles

– Bring the power tool into the working position.

– Adjust to a 0 ° bevel angle.

– Tilt the blade guard

5.x

toward the rear to the stop.

Checking:

(see figure M1)

– Set an angle gauge to 90 ° and place it on the saw table

17

.

The leg of the angle gauge must be flush with the saw blade

32

over the complete length.

Adjusting:

(see figure M2)

– Loosen screw

67

.

The 0 ° stop

28

can now be moved.

– Loosen locking lever

26

.

– Move handwheel

19

toward the 0° stop until the leg of the

angle gauge is flush with the saw blade over the complete

length.

– Hold the handwheel in this position and tighten locking le-

ver

26

again.

– Tighten screw

67

again.

When the angle indicator

61

is not in line with the 0 ° mark of

scale

27

, loosen screw

68

with a commercially available Phil-

lips screwdriver and align the angle indicator alongside the 0 °

mark.

Repeat the above mentioned worksteps accordingly for the

45 ° bevel angle (loosening screw

69

; moving the 45° stop

25

). In this, the angle indicator

61

must not be misadjusted.

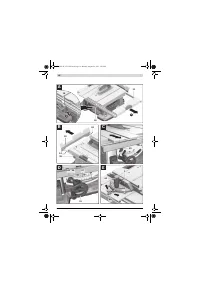

Parallelism of the Saw Blade to the Guide Grooves of the

Angle Stop (see figure N)

– Bring the power tool into the working position.

– Tilt the blade guard

5.x

toward the rear to the stop.

Checking:

– With a pencil, mark the first visible saw tooth on the left

side that projects above the insert plate.

– Set an angle gauge to 90 ° and place it on the edge of the

guide groove

9

.

– Move the leg of the angle gauge until it touches the marked

saw tooth, and read the clearance between saw blade and

guide groove.

Bevel angle

Max. workpiece height

[mm]

0 °

79

45 °

56

OBJ_BUCH-1375-002.book Page 38 Monday, August 29, 2011 5:05 PM