Электропилы Bosch GTS 10 XC - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

36

| English

1 619 929 K16 | (29.8.11)

Bosch Power Tools

Operation

f

Before any work on the machine itself, pull the mains

plug.

Transport and Working Position of the Saw Blade

Transport Position

– Turn the handwheel

19

in anticlockwise direction until the

teeth of the saw blade

32

are positioned below the saw ta-

ble

17

.

For additional information on transport, see page 39.

Working Position

– Turn the crank

20

clockwise, until the teeth of the saw

blade

32

are positioned above the workpiece.

Note:

Take care that the blade guard is properly positioned.

When sawing, it must always face against the workpiece.

Increasing the Size of the Saw Table

Long workpieces must be underlaid or supported at their free

end.

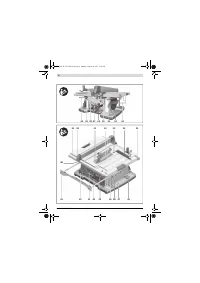

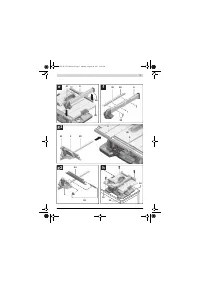

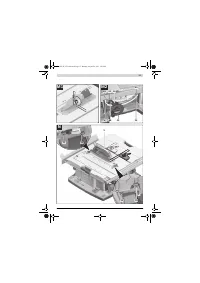

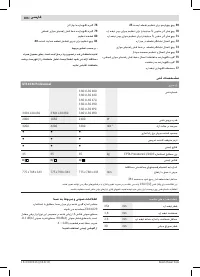

Table Width Enlargement (see figure A)

The table width enlargement

11

enlarges the saw table

17

to-

ward the right by 435 mm (max.).

– Completely pull the clamping handle

18

for the table width

enlargement upward.

– Pull out the table width enlargement

11

to the desired

length (also see “Adjusting the Parallel Guide With the Saw

Table Extended”, page 36).

– Press clamping handle

18

downward.

The table width enlargement is now locked.

Table Extension (see figure B)

The table extension

10

extends saw table

17

to the rear by

520 mm (max.).

– Loosen the locking screws

38

on the guide rods

24

.

– Pull out the table extension

10

to the desired length.

– To lock the position, firmly tighten both locking screws

38

.

For heavy workpieces, it may be required to support the table

extension.

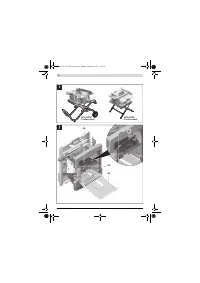

Sliding Table (see figure C)

With the sliding table

2

, workpieces to a maximum width of

350 mm can be sawn.

At the same time, a higher precision is achieved during saw-

ing, especially in conjunction with the angle stop

3

. (see

“Sawing Mitre Angles with the Sliding Table”, page 38)

– Completely pull the clamping lever

29

for the sliding table

upward.

In this manner, the sliding table can be moved both toward

the front as well as toward the rear to the stop.

Adjusting the Cutting Angle

To ensure precise cuts, the basic adjustment of the machine

must be checked and adjusted as necessary after intensive

use (see “Checking and Adjusting the Basic Adjustment”,

page 38).

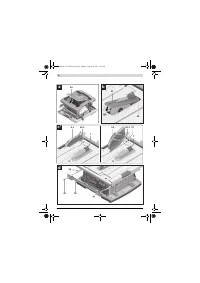

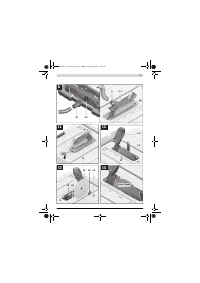

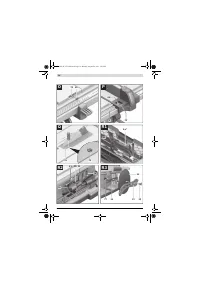

Adjusting Bevel Angles (Saw Blade) (see figure D)

The bevel angle can be set in a range from – 1 ° to +47 ° .

– Turn locking lever

26

in anticlockwise direction.

Note:

By completely loosening the locking knob, the saw

blade tilts approx. to the 30 ° position by means of gravity

force.

– Push or pull handwheel

19

alongside the connecting link

until the angle indicator

61

indicates the desired bevel an-

gle.

– Hold the handwheel in this position and tighten locking le-

ver

26

again.

For quick and precise setting of the standard 0 ° and 45 °

angles, factory-set stops have been provided for.

Adjusting Mitre Angles (Angle Stop) (see figure E)

The mitre angle can be set in the range from 60 ° (left side) to

60 ° (right side).

– Loosen the locking knob

62

in case it is tightened.

– Turn the angle stop until the angle indicator

63

indicates

the requested mitre angle.

– Tighten the locking knob

62

again.

For quick and precise setting of frequently used mitre an-

gles

, stop screw for the 45 ° angles (left and right) and 0 °

have been provided for on angle stop

3

.

– Loosen the locking knob

62

in case it is tightened.

– Tilt the adjustment piece

80

outward.

– Turn the angle stop in such a manner that the thread of the

desired stop screw is positioned rightward to the adjust-

ment piece.

– Tilt adjustment piece

80

inward and turn the angle stop un-

til the thread of the stop screw faces against the adjust-

ment piece.

– Tighten the locking knob

62

again.

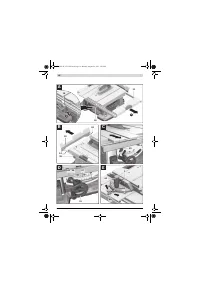

Adjusting the Parallel Guide

The parallel guide

8

can be positioned either left (black scale)

or right (silver scale) from the saw blade.

The mark in the lens

64

indicates the set clearance of the par-

allel guide to the saw blade on the scale

1

.

Position the parallel guide on the desired side of the saw

blade (see “Mounting the Parallel Guide”, page 34).

With the Saw Table not Extended

– Loosen clamping handle

47

of parallel guide

8

.

Move the parallel guide until the mark in the lens

64

indi-

cates the desired clearance to the saw blade.

When the saw table is not extended, the bottom labelling of

the silver scale applies

1

.

– To lock the parallel guide, press clamping handle

47

down

again.

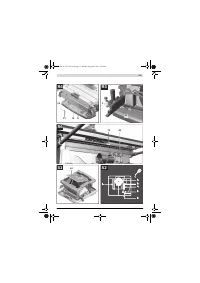

With the Saw Table Extended (see figure F)

– Position the parallel guide on the right side of the saw

blade.

Move the parallel guide until the mark in the lens

64

indi-

cates 33 cm on the bottom scale.

To lock the parallel guide, press clamping handle

47

down

again.

OBJ_BUCH-1375-002.book Page 36 Monday, August 29, 2011 5:05 PM