Электропилы Bosch GTS 10 XC - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

English |

35

Bosch Power Tools

1 619 929 K16 | (29.8.11)

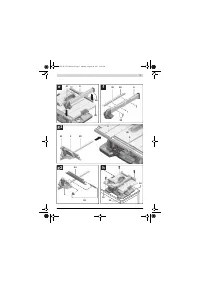

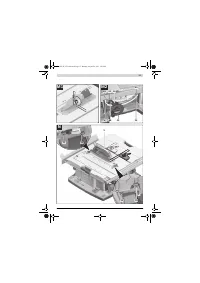

Mounting to a Bosch Saw Stand (see figure i)

With the height-adjustable legs, Bosch saw stands (e. g.

GTA 60 W, GTA 6000) provide firm support for the power

tool on any surface.

f

Read all safety warnings and instructions included with

the worktable.

Failure of observing safety warnings and

instructions can lead to electrical shock, fire and/or cause

serious injuries.

f

Assemble the worktable properly before mounting the

power tool.

Perfect assembly is important in order to pre-

vent the risk of collapsing.

– Mount the power tool in transport position on the saw

stand.

Dust/Chip Extraction

Dusts from materials such as lead-containing coatings, some

wood types, minerals and metal can be harmful to one’s

health. Touching or breathing-in the dusts can cause allergic

reactions and/or lead to respiratory infections of the user or

bystanders.

Certain dusts, such as oak or beech dust, are considered as

carcinogenic, especially in connection with wood-treatment

additives (chromate, wood preservative). Materials contain-

ing asbestos may only be worked by specialists.

– Always use dust extraction.

– Provide for good ventilation of the working place.

– It is recommended to wear a P2 filter-class respirator.

Observe the relevant regulations in your country for the mate-

rials to be worked.

The dust/chip extraction can be blocked by dust, chips or

workpiece fragments.

– Switch the machine off and pull the mains plug from the

socket outlet.

– Wait until the saw blade has come to a complete stop.

– Determine the cause of the blockage and correct it.

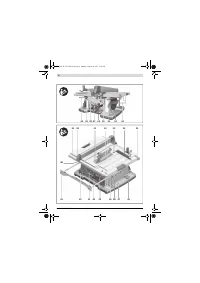

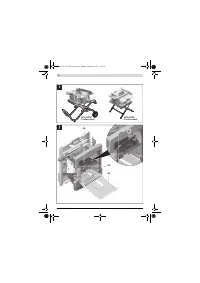

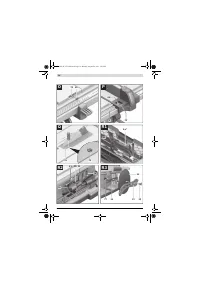

Cleaning the Lower Saw Blade Cover (see figure j)

The lower saw blade cover

54

can be opened for removal of

workpiece fragments and large chips.

– Switch the machine off and pull the mains plug from the

socket outlet.

– Wait until the saw blade has come to a complete stop.

– Tilt the machine on it’s side.

– Remove bottom plate

44

.

– Loosen fastening screw

55

and open the lower saw blade

cover

54

.

– Remove workpiece fragments and chippings.

– Shut the lower saw blade cover and screw it on again.

Screw the bottom plate on again.

– Bring the power tool into the working position.

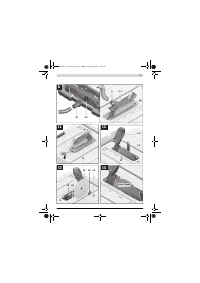

External Dust Extraction (see figure k)

To connect a vacuum cleaner to the sawdust ejector

40

, use

the supplied extraction adapter

41

.

– Firmly attach the extraction adapter

41

and the vacuum

hose.

– Additionally, a dust extraction system can be connected

with the Y-adapter (accessory) to vacuum connection

6

, to

increase the extraction performance.

The vacuum cleaner must be suitable for the material being

worked.

When vacuuming dry dust that is especially detrimental to

health or carcinogenic, use a special vacuum cleaner.

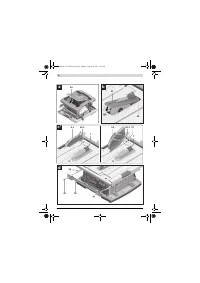

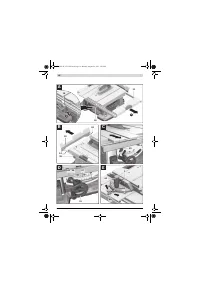

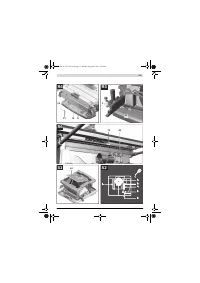

Changing the Saw Blade (see figures l1

–

l4)

f

Before any work on the machine itself, pull the mains

plug.

f

When mounting the saw blade, wear protective gloves.

Danger of injury when touching the saw blade.

Use only saw blades whose maximum permitted speed is

higher than the no-load speed of the power tool.

Use only saw blades that correspond with the characteristic

data given in these operation instructions and that are tested

and marked in accordance with EN 847-1.

Use only saw blades recommended by the tool manufacturer,

and suitable for sawing the materials to be cut.

Removing the Saw Blade

– Using a screwdriver, raise the insert plate

31

at the front

and remove it from the tool basin.

– Turn crank

20

clockwise to the stop, so that the saw blade

32

is in the highest possible position above the saw table.

– Tilt the blade guard

5.x

toward the rear to the stop.

– Turn the clamping nut

56

with the ring spanner

15

(24 mm) and at the same time, pull the spindle lock lever

57

until it engages.

– Keep the spindle lock lever pulled and unscrew the clamp-

ing nut turning in anticlockwise direction.

– Remove the clamping flange

58

.

– Remove the saw blade

32

.

Mounting the Saw Blade

If required, clean all parts to be mounted prior to assembly.

– Place the new saw blade onto the supporting flange

59

of

the tool spindle

60

.

Note:

Do not use saw blades that are too small. The clearance

between saw blade and riving knife must not exceed 5 mm

(max.).

f

When mounting the saw blade, pay attention that the

cutting direction of the teeth (arrow direction on the

saw blade) corresponds with the direction of the arrow

on the blade guard!

– Mount the clamping flange

58

and the clamping nut

56

.

– Turn the clamping nut

56

with the ring spanner

15

(24 mm) and at the same time, pull the spindle lock lever

57

until it engages.

– Tighten the clamping nut in clockwise direction.

(Tightening torque approx. 15 – 23 Nm)

– Reinsert the insert plate

31

.

– Tilt blade guard

5.x

down again.

OBJ_BUCH-1375-002.book Page 35 Monday, August 29, 2011 5:05 PM