Шуруповерты GRAPHITE Energy+ 18 V 58G020 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

14

15

BAT TERY LEVEL INDICATION

The battery is equipped with signalisation of the battery level (3

LED diodes) (

14

). To check battery level status, press the button

for battery level indication (

13

) (

fig. C

). When all diodes are lit,

the battery level is high. When 2 diodes are on, the battery is

partially discharged. When only one diode is lit, the battery is

discharged and must be recharged.

SPINDLE BRAKE

Drill is equipped with electronic brake that stops the spindle

immediately after the switch button (

9

) is released. The brake

ensures precision when screwing or drilling and prevents free

spindle rotation after switching off.

OPERATION / SET TINGS

SWITCHING ON / SWITCHING OFF

Switching on

– press the switch button (

9

).

Switching off

– release the switch button (

9

).

Each time the switch button (

9

) is pressed, the LED diode (

10

)

lights up to illuminate the workplace.

ROTATIONAL SPEED CONTROL

Increase or reduce pressure on the switch button (

9

) to adjust

drilling or driving speed while operating. Speed adjustment

allows for a soft start, which prevents dill slipping when drilling

holes in gypsum or glaze, and allows for operation control when

driving screws in and out.

OVERLOAD CLUTCH

Set the torque adjustment ring (

3

) in appropriate position

to permanently set overload clutch to defined torque value.

When the set torque is reached, overload clutch disconnects

automatically. It prevents from driving screws too deep or

damaging the drill.

TORQUE ADJUSTMENT

•

Different screws and materials require different torque to be

applied.

•

The bigger the number corresponding to given position, the

bigger is the torque (

fig. D

).

•

Set the torque adjustment ring (

3

) to appropriate torque value.

•

Always start operation with low torque.

•

Increase the torque gradually until obtaining desired results.

•

Use higher settings to undo screws.

•

When drilling, choose setting marked with the drill symbol.

The torque is the greatest with this setting.

•

Knowledge how to choose appropriate torque setting comes

with practice.

Setting the torque adjustment ring in the drilling position

deactivates the overload clutch.

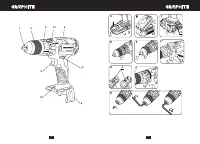

WORKING TOOL INSTALLATION

•

Set the direction selector switch (

5

) in the middle position.

•

By turning the ring of the quick release chuck (

2

) counter

clockwise (see mark on the ring) you can spread jaws enough

to insert drill or driver bit (

fig. E

).

•

To fix the working tool, turn the ring of the quick release chuck

(

2

) clockwise and tighten.

Deinstallation of the tool is similar to installation, only the

sequence of actions is reversed.

Make sure the tool position is correct when installing drill or

driver bit in the quick release chuck. Use additional magnetic

adapter as an extension when using short driver bits.

RIGHT-LEFT DIRECTION OF ROTATION

Choose direction of spindle rotation with the direction selector

switch (

5

) (

fig. F

).

Clockwise rotation

– set the switch (

5

) to the extreme left

position.

Counter-clockwise rotation

– set the switch (

5

) to the extreme

right position.

* In certain cases position of the switch related to rotation may be different

than specified. Please refer to graphic signs located on the switch or tool

body.

Safe position of the direction selector switch (

5

) is in the middle,

it prevents accidental starting of the power tool.

•

Drill cannot be started, when the switch is in this position.

•

Use this position of the switch to change drills or bits.

•

Before starting the tool make sure the position of the direction

selector switch (

5

) is correct.

Do not change direction of rotation when the drill spindle

is rotating.

CHANGE OF GEAR

Gear switch (

4

) (

fig. H

) allows to increase the range of rotational

speed.

Gear I:

small speed range, big torque

Gear II:

greater speed range, small torque.

Set the gear switch in position appropriate for the works to

perform. When the switch is blocked and cannot be moved, turn

the spindle slightly.

Never change the gear switch position when the drill is

operating. It may damage the power tool.

Long lasting drilling at low rotational speed of the spindle

may cause motor overheating. Long lasting drilling at

low rotational speed of the spindle may cause motor

overheating.

OPERATION MODE SWITCH

Operation mode selection ring (

15

) (

fig. I

) allows to select the

tool function:

• Screw symbol

– operation with overload clutch active

• Drill symbol

– drilling. The highest torque is available

(overload clutch deactivated).

• Hammer symbol

– impact drilling (overload clutch

deactivated).

Setting the operation mode selection ring in the position for

drilling or impact drilling deactivates the overload clutch.

Do not try to change position of the operation mode

selection ring when the tool spindle is rotating. Such action

can cause serious damage of the power tool.

HOLDER

The drill provides convenient holder (

6

) that allows to e.g. hang

the tool on a tool belt when working at heights.

OPERATION AND MAINTENANCE

Remove the battery from the device before commencing

any activities related to installation, adjustment, repair or

maintenance.

MAINTENANCE AND STORAGE

•

Cleaning the device after each use is recommended.

•

Do not use water or any other liquid for cleaning.

•

Clean the tool with a dry cloth or blow through with

compressed air at low pressure.

•

Do not use any cleaning agents or solvents, they may damage

plastic parts.

•

Clean ventilation holes in the motor casing regularly to

prevent device overheating.

•

Always store the tool in a dry place, beyond reach of children.

•

Store the device with the battery removed.

QUICK RELEASE CHUCK REPLACEMENT

Quick-release chuck is screwed onto spindle of the drill and

additionally secured with a screw.

•

Set the direction selector switch (

5

) in the middle position.

•

Open jaws of quick release chuck (

1

) and unscrew the fixing

screw (left-hand thread) (

fig. H

).

•

Install hexagonal key in the quick release chuck and tap the

other end of the key.

•

Unscrew the quick release chuck.

•

Installation of the quick release chuck is similar to

deinstallation, only the sequence of actions is reversed.

All defects should be repaired by service workshop authorized

by the manufacturer.

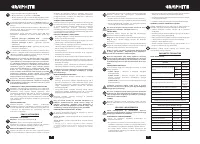

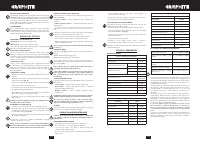

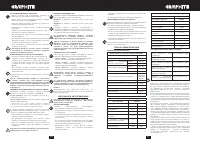

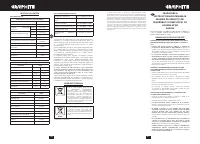

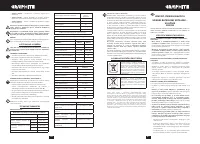

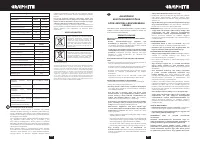

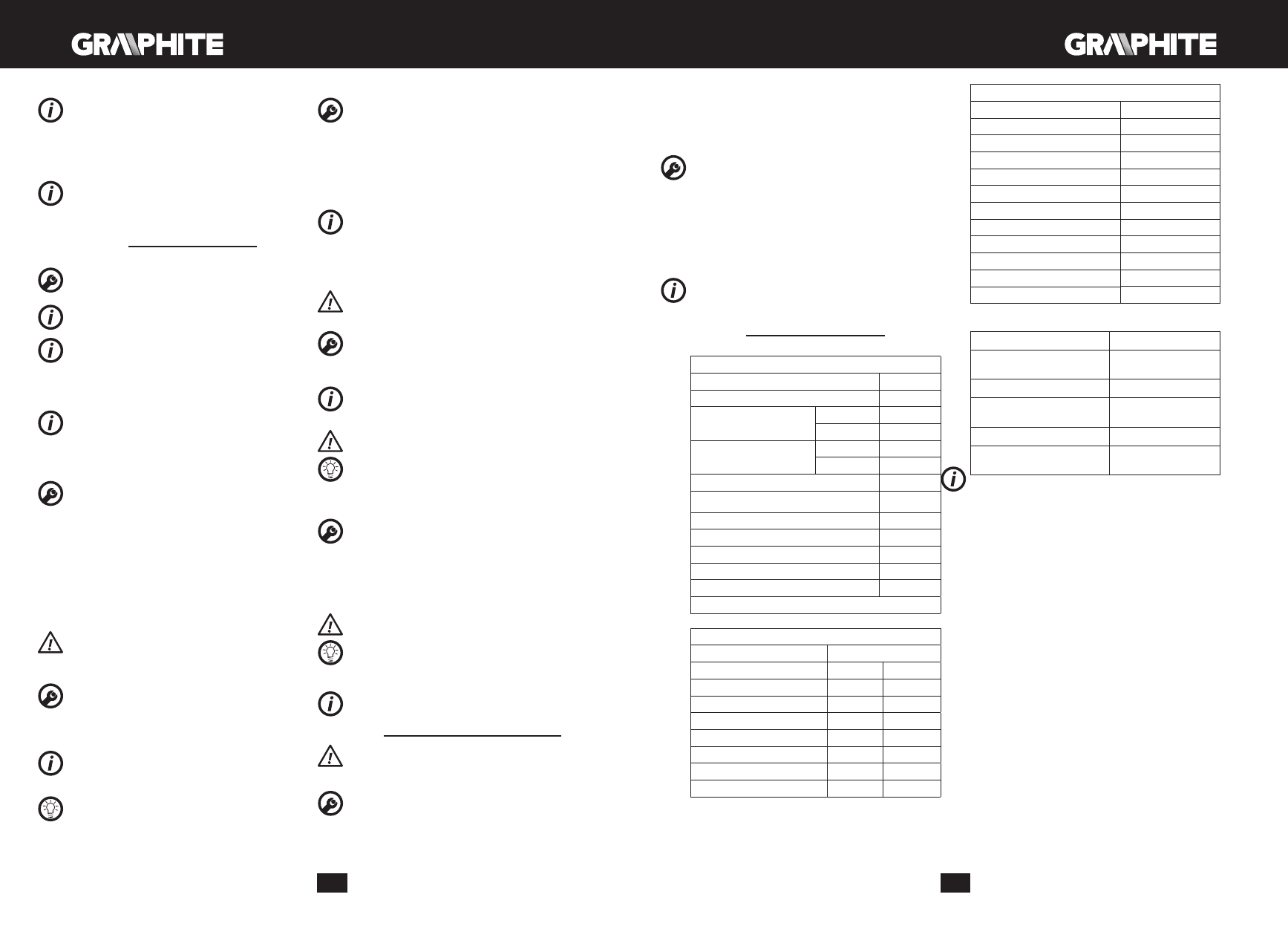

TECHNICAL PARAMETERS

RATED PARAMETERS

Cordless drill with impact 58G020

Parameter

Value

Battery voltage

18 V DC

Range of idle rotational speed

gear I

0-500 min

-1

gear II

0-1700 min

-1

Impact speed on idle

gear I

0-7500 min

-1

gear II

0-25500 min

-1

Range of quick release chuck

2-13 mm

Torque control range

1–16 + drilling,

impact drilling

Max. torque (soft drive)

38 Nm

Max. torque (hard drive)

58 Nm

Protection class

III

Weight

1,2 kg

Year of production

2018

58G020 defines type and indication of the device

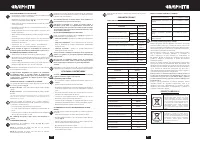

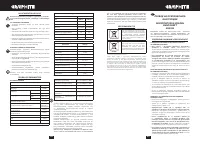

Graphite Energy+ System Battery

Parameter

Value

Battery

58G001

58G004

Battery voltage

18 V DC

18 V DC

Battery type

Li-Ion

Li-Ion

Battery capacity

2000 mAh

4000 mAh

Ambient temperature range

4

0

C – 40

0

C

4

0

C – 40

0

C

Charging time for charger 58G002

1 h

2 h

Weight

0,400 kg

0,650 kg

Year of production

2018

2018

Graphite Energy+ System Charger

Parameter

Value

Charger type

58G002

Supply voltage

230 V AC

Power supply frequency

50 Hz

Charging voltage

22 V DC

Max. charging current

2300 mA

Ambient temperature range

4

0

C – 40

0

C

Charging time of the battery 58G001

1 h

Charging time of the battery 58G004

2 h

Protection class

II

Weight

0,300 kg

Year of production

2018

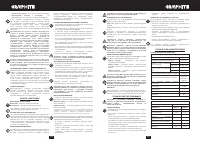

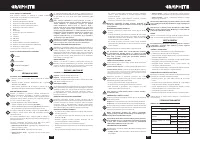

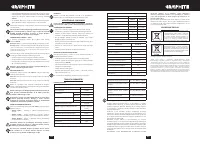

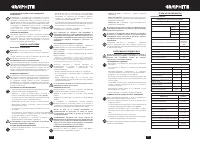

NOISE LEVEL AND VIBRATION PARAMETERS

Sound pressure (drilling)

Lp

A

= 77,5 dB(A) K= 3 dB(A)

Sound pressure (drilling with

impact)

Lp

A

= 85,5 dB(A) K= 3 dB(A)

Sound power (drilling)

Lw

A

= 88,5 dB(A) K= 3 dB(A)

Sound power (drilling with

impact)

Lw

A

= 96,5 dB(A) K= 3 dB(A)

Vibration acceleration (drilling)

a

h

= 2,04 m/s

2

K= 1,5 m/s

2

Vibration acceleration (drilling

with impact)

a

h

= 11,72 m/s

2

K= 1,5 m/s

2

Noise and vibration information

Noise produced by the device is defined with: level of produced

sound pressure Lp

A

and level of sound power Lw

A

(where K is

measurement uncertainty). Vibrations produced by the device

are defined with vibration acceleration value a

h

(where K is

measurement uncertainty).

Sound pressure Lp

A

, sound power Lw

A

and vibration acceleration

ah specified in this manual have been measured in accordance

with EN 60745-1. Specified vibration level a

h

can be used

to compare tools and for initial evaluation of exposition to

vibrations.

Specified vibration level is representative for main applications

of the device. When the device is used for other purposes or

with different working tools, the vibration level may change.

Insufficient or too rare maintenance may increase vibration

level. The abovementioned factors may lead to higher exposure

to vibrations during whole working time.

To precisely define exposure to vibrations, include periods

when the device is switched off and when it is switched on

but not used for working. Once all factors have been carefully

considered, total exposition to vibrations may be significantly

lower.

To protect the user from results of exposure to vibrations, use

additional safety measures such as: device and working tool

periodic maintenance, proper hand temperature conditions,

good work organisation.