Котел Immergas Mini Eolo 24 3 E - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

27

STMiE3E ed 09/11

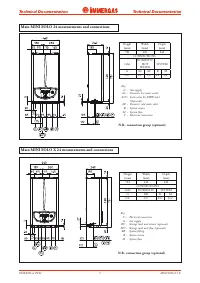

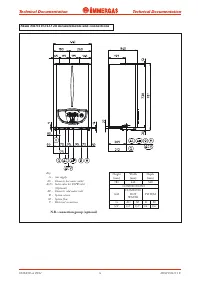

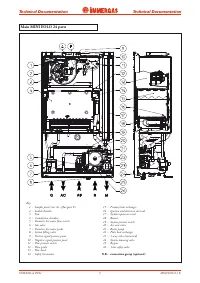

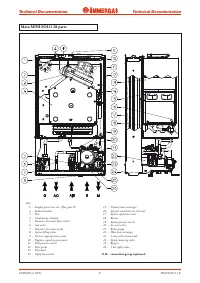

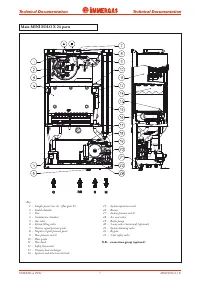

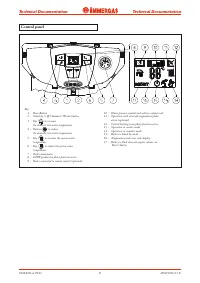

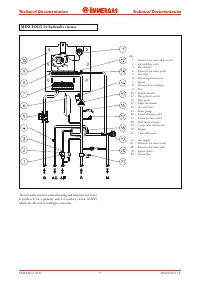

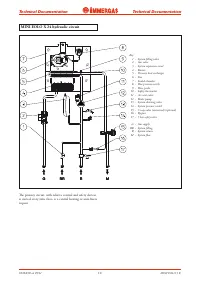

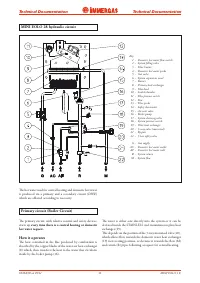

MINI EOLO 3 E

Technical Documentation

Technical Documentation

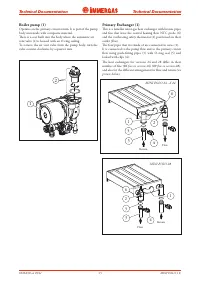

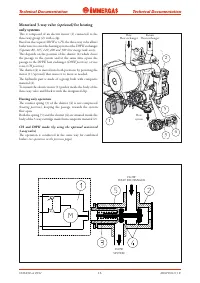

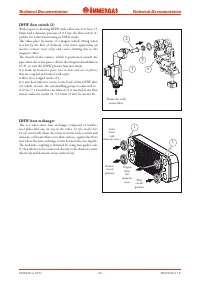

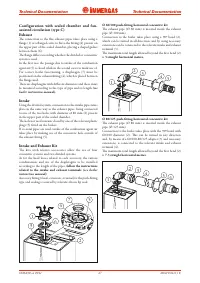

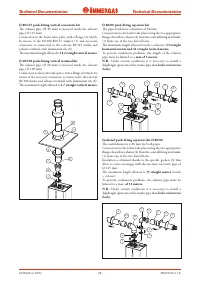

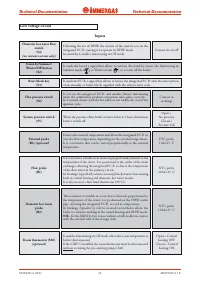

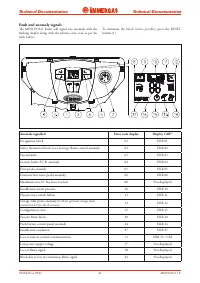

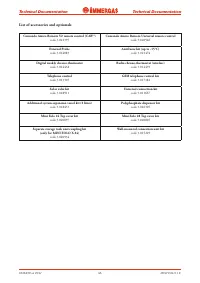

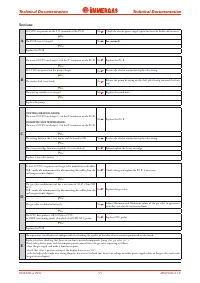

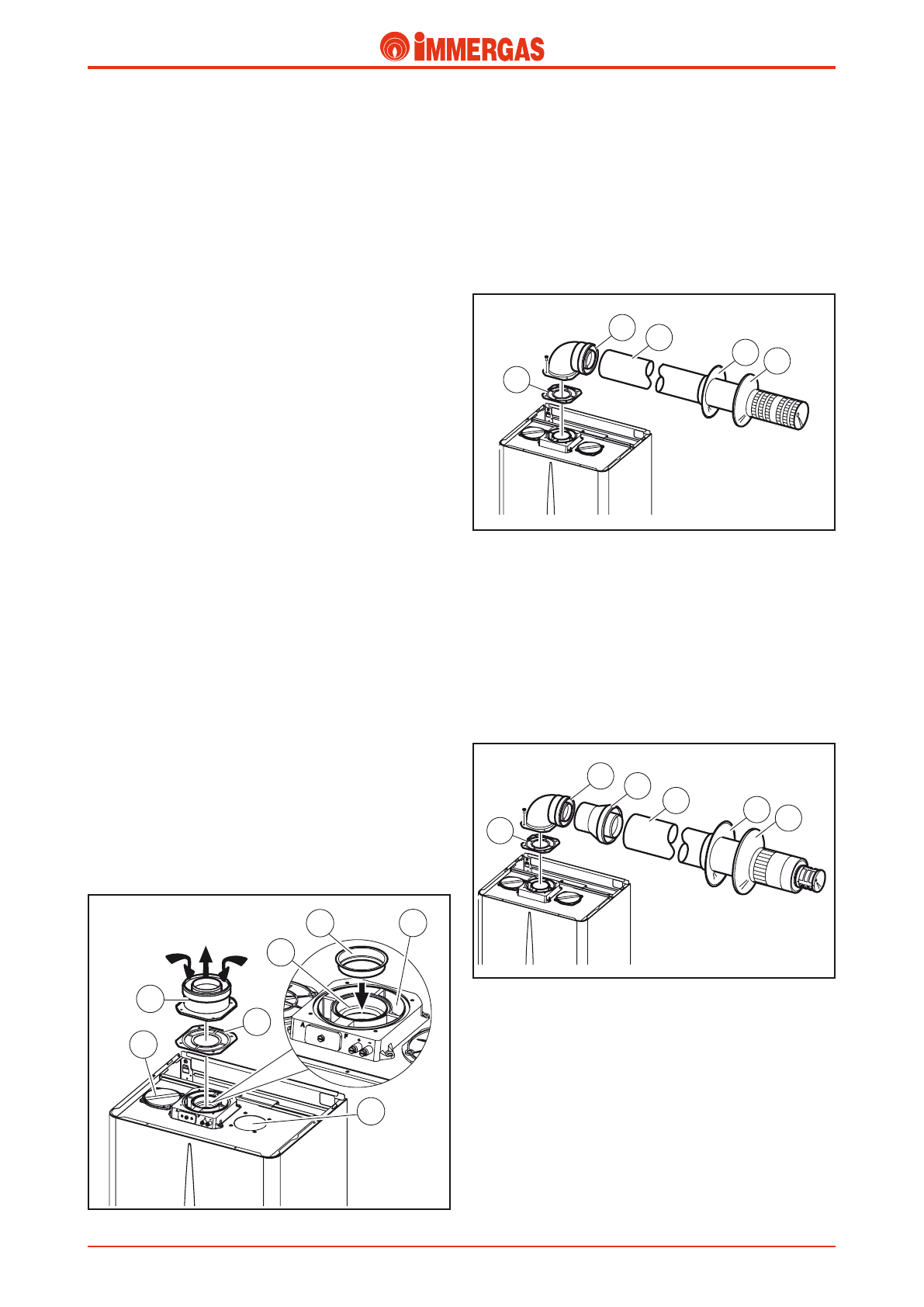

Ø 60/100 push-fitting horizontal concentric kit

The exhaust pipe (Ø 60 mm) is inserted inside the exhaust

pipe (Ø 100 mm).

Connection to the boiler takes place using a 90º bend (2),

which can be turned in all directions and by using necessary

extensions can be connected to the relevant intake and exhaust

terminal (3).

The maximum total length allowed beyond the first bend (2)

is

3 straight horizontal metres.

Ø 80/125 push-fitting horizontal concentric kit

The exhaust pipe (Ø 80 mm) is inserted inside the exhaust

pipe (Ø 125 mm).

Connection to the boiler takes place with the 90º bend with

60/100 diameter (2). This can be turned in any direction

and, by means of a 60/100-80/125 adapter (3) and necessary

extensions, is connected to the relevant intake and exhaust

terminal (4).

The maximum total length allowed beyond the first bend (2)

is

7.3 straight horizontal metres.

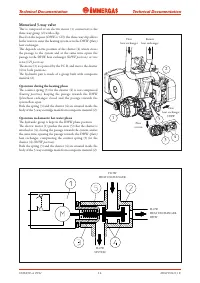

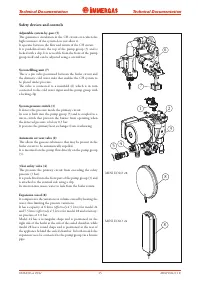

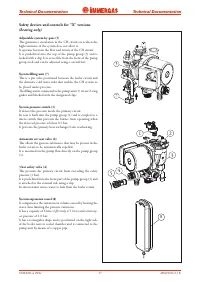

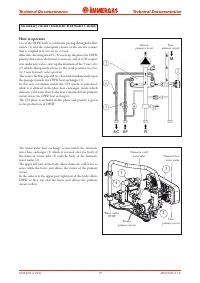

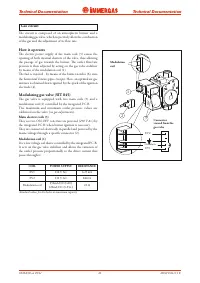

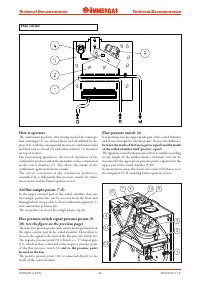

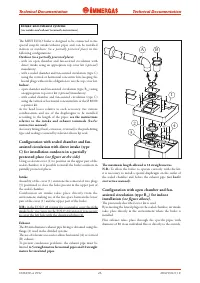

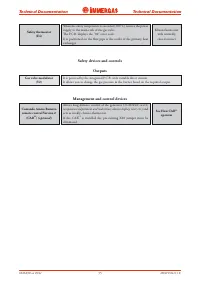

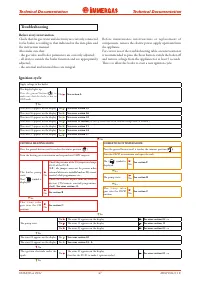

Configuration with sealed chamber and fan-

assisted circulation (type C)

Exhaust

The connection to the flue exhaust pipes takes place using a

flange (1) or a flanged curve to fix to the fitting (4) present on

the upper part of the sealed chamber, placing a shaped gasket

between them (6).

The flange differs according whether the divided or concentric

system is used.

In the first case the passage due to intake of the combustion

agent air (5) is closed while in the second case it is made use of.

For correct boiler functioning, a diaphragm (7) must be

positioned on the exhaust fitting (4), which is placed between

the flange used.

There are diaphragms with different diameters and these must

be mounted according to the type of pipe and its length

(see

boiler instruction manual).

Intake

Using the divided system, connection to the intake pipes takes

place in the same way as the exhaust pipes, being connected

to one of the two holes with diameter of 80 mm (2) present

in the upper part of the sealed chamber.

The hole not used remains closed by one of the relevant plastic

plugs (3) fitted on the boilers.

If co-axial pipes are used, intake of the combustion agent air

takes place by making use of the concentric hole outside of

the exhaust fitting (5).

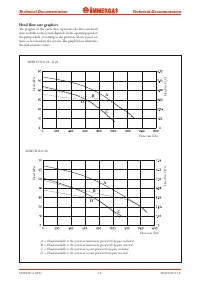

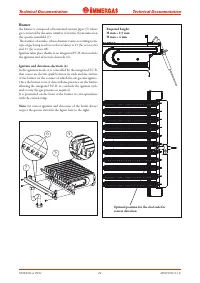

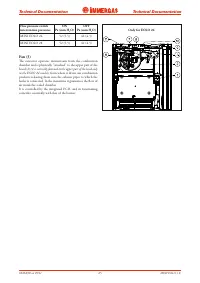

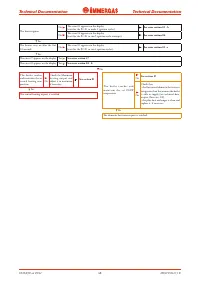

Intake and Exhaust Kit

The kits with relative accessories allow the use of four

concentric systems and two divided systems.

As for the head losses related to each accessory, the various

combinations and use of the diaphragms to be installed

according to the length of the pipes,

follow the instructions

related to the intake and exhaust terminals

(see boiler

instruction manual).

Accessory fitting (bends, extensions, terminals) is the push-fitting

type and sealing is assured by relevant silicon lip seals.

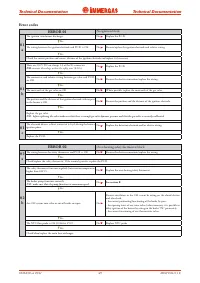

1

3

2

5 6

4

1

3

2

4 5

1

2

3

4

5

7

6

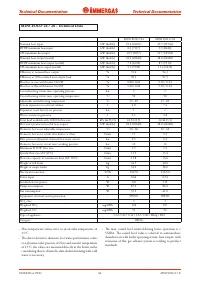

Характеристики

Остались вопросы?Не нашли свой ответ в руководстве или возникли другие проблемы? Задайте свой вопрос в форме ниже с подробным описанием вашей ситуации, чтобы другие люди и специалисты смогли дать на него ответ. Если вы знаете как решить проблему другого человека, пожалуйста, подскажите ему :)