Дрели Bosch GBM 1600 RE - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

English |

13

Bosch Power Tools

1 609 92A 2GV | (27.7.16)

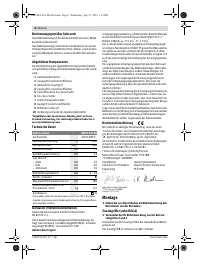

Noise/Vibration Information

Sound emission values determined according to

EN 60745-2-1.

Typically the A-weighted noise levels of the product are:

Sound pressure level 85 dB(A); Sound power level 96 dB(A).

Uncertainty K = 3 dB.

Wear hearing protection!

Vibration total values a

h

(triax vector sum) and uncertainty K

determined according to EN 60745-2-1:

Drilling into metal: a

h

< 2.5 m/s

2

, K = 1.5 m/s

2

.

The vibration level given in this information sheet has been

measured in accordance with a standardised test given in

EN 60745 and may be used to compare one tool with anoth-

er. It may be used for a preliminary assessment of exposure.

The declared vibration emission level represents the main ap-

plications of the tool. However if the tool is used for different

applications, with different accessories or insertion tools or is

poorly maintained, the vibration emission may differ. This

may significantly increase the exposure level over the total

working period.

An estimation of the level of exposure to vibration should also

take into account the times when the tool is switched off or

when it is running but not actually doing the job. This may sig-

nificantly reduce the exposure level over the total working

period.

Identify additional safety measures to protect the operator

from the effects of vibration such as: maintain the tool and the

accessories, keep the hands warm, organisation of work pat-

terns.

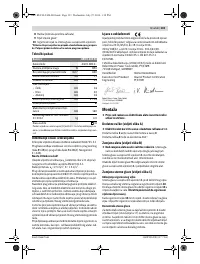

Declaration of Conformity

We declare under our sole responsibility that the product de-

scribed under “Technical Data” is in conformity with all rele-

vant provisions of the directives 2011/65/EU, until

19 April 2016: 2004/108/EC, from 20 April 2016 on:

2014/30/EU, 2006/42/EC including their amendments and

complies with the following standards: EN 60745-1,

EN 60745-2-1, EN 50581.

Technical file (2006/42/EC) at:

Robert Bosch Power Tools GmbH, PT/ETM9,

70538 Stuttgart, GERMANY

Robert Bosch Power Tools GmbH

70538 Stuttgart, GERMANY

Stuttgart, 01.01.2017

Assembly

Before any work on the machine itself, pull the mains

plug.

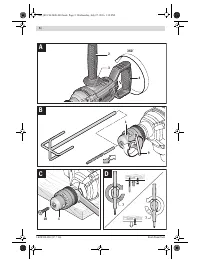

Auxiliary handles (see figure A)

Operate your machine only with the auxiliary handles 2

and 4.

Screw the auxiliary handle

2

into the thread

3

on the motor

housing.

The auxiliary handle

4

can be rotated through 360 °.

Changing the Tool (see figure B)

Wear protective gloves when changing the tool.

The

drill chuck can become very hot during longer work peri-

ods.

Open the key type drill chuck

1

by turning until the tool can be

inserted. Insert the tool.

Insert the chuck key

9

into the corresponding holes of the key

type drill chuck

1

and clamp the tool uniformly.

Replacing the Drill Chuck (see figure C)

Removing the Securing Screw

The key type drill chuck

1

is secured with a securing screw

10

against unintentional loosening. Open the drill chuck

1

com-

pletely and unscrew the securing screw

10

by turning in

clockwise direction.

Please observe that the securing

screw has a left-hand thread.

If the securing screw

10

is seated tightly, apply a screwdriver

to the screw head and loosen the securing screw by giving a

blow onto the handle of the screwdriver.

Removing the Drill Chuck

To dismount the key type drill chuck

1

position an open-end

spanner (size 17 mm) against the nut on the drive spindle.

Firmly hold the key type drill chuck with one hand and with the

other hand, turn the open-end spanner in anticlockwise direc-

tion until the drill chuck is released from the tapered drill spin-

dle.

Mounting the Drill Chuck

Keep the drill spindle taper and the drill hole of the drill

chuck free from grease and debris.

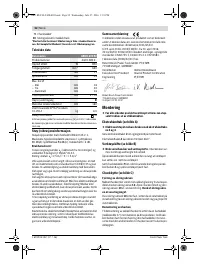

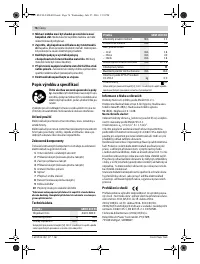

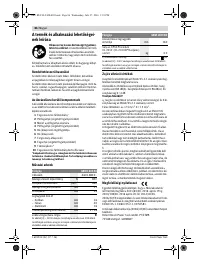

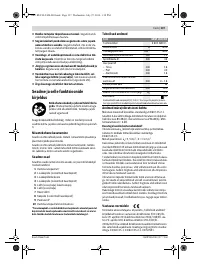

Spindle collar dia.

mm

43

Max. drilling dia.

– Steel

– Wood

– Aluminium

mm

mm

mm

16

40

16

Chuck clamping range

mm

3 – 16

Right/left rotation

Maximum stirrer paddle diameter

mm

160

Weight according to EPTA-

Procedure 01:2014

kg

3.0

Protection class

/

II

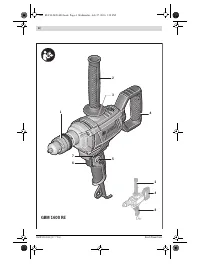

Rotary drill

GBM 1600 RE

The values given are valid for a nominal voltage [U] of 230 V. For differ-

ent voltages and models for specific countries, these values can vary.

Henk Becker

Executive Vice President

Engineering

Helmut Heinzelmann

Head of Product Certification

PT/ETM9

OBJ_BUCH-2420-003.book Page 13 Wednesday, July 27, 2016 1:18 PM

Содержание

- 90 Указания по технике безопасности для дрелей

- 91 Дополнительные предупредительные; Описание продукта и услуг; Применение по назначению

- 92 Технические данные; Заявление о соответствии; Сборка

- 93 Отсос пыли и стружки; Работа с инструментом; Включение электроинструмента

- 94 Техобслуживание и сервис; Техобслуживание и очистка; Утилизация

Характеристики

Остались вопросы?Не нашли свой ответ в руководстве или возникли другие проблемы? Задайте свой вопрос в форме ниже с подробным описанием вашей ситуации, чтобы другие люди и специалисты смогли дать на него ответ. Если вы знаете как решить проблему другого человека, пожалуйста, подскажите ему :)