Сварочное оборудование Awelco MIG ONE - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

·

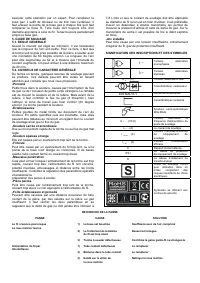

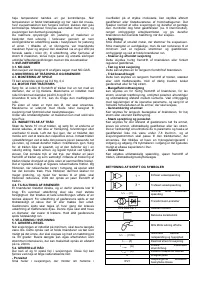

Very thick or wide welding

Can be caused by moving the torch too slowly.

·

Wire burns back

It can be caused by wire feed slipping, loose or damaged

welding tip, poor wire, nozzle held too close to work or

voltage too high.

· Little

penetration

It can be caused by moving torch too fast, too low voltage

setting or incorrect feed setting, reversed polarity, insufficient

blunting and distance between strips. Take care of

operational parameters adjustment and improve the

preparation of the workpieces.

· Workpiece’s

piercing

It may be caused by moving the welding torch too slow, too

high welding power or by an invalid wire feeding.

·

Heavy spatter and porosity

It can be caused by nozzle too far from work, dirt on work or

by low gas flow. You have to the two parameters, remeber

that gas has not to be lower than 7-8 liters/ min. and that the

current of welding is appropriated to the wire you are using. It

is advisable to have a pressure reducer of input and output.

On the manometer you can read the range expressed in liter.

·

Welding arc instability

It may be caused by an insufficient welding voltage, irregular

wire feed, insufficient protective welding gas.

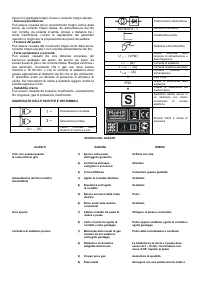

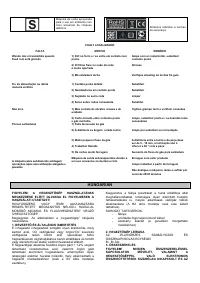

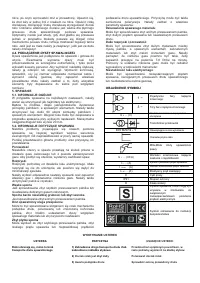

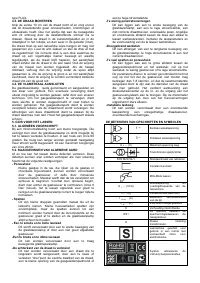

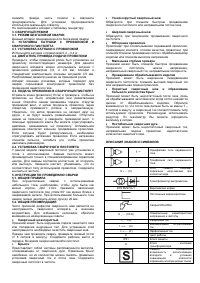

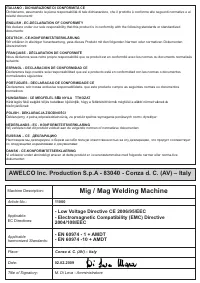

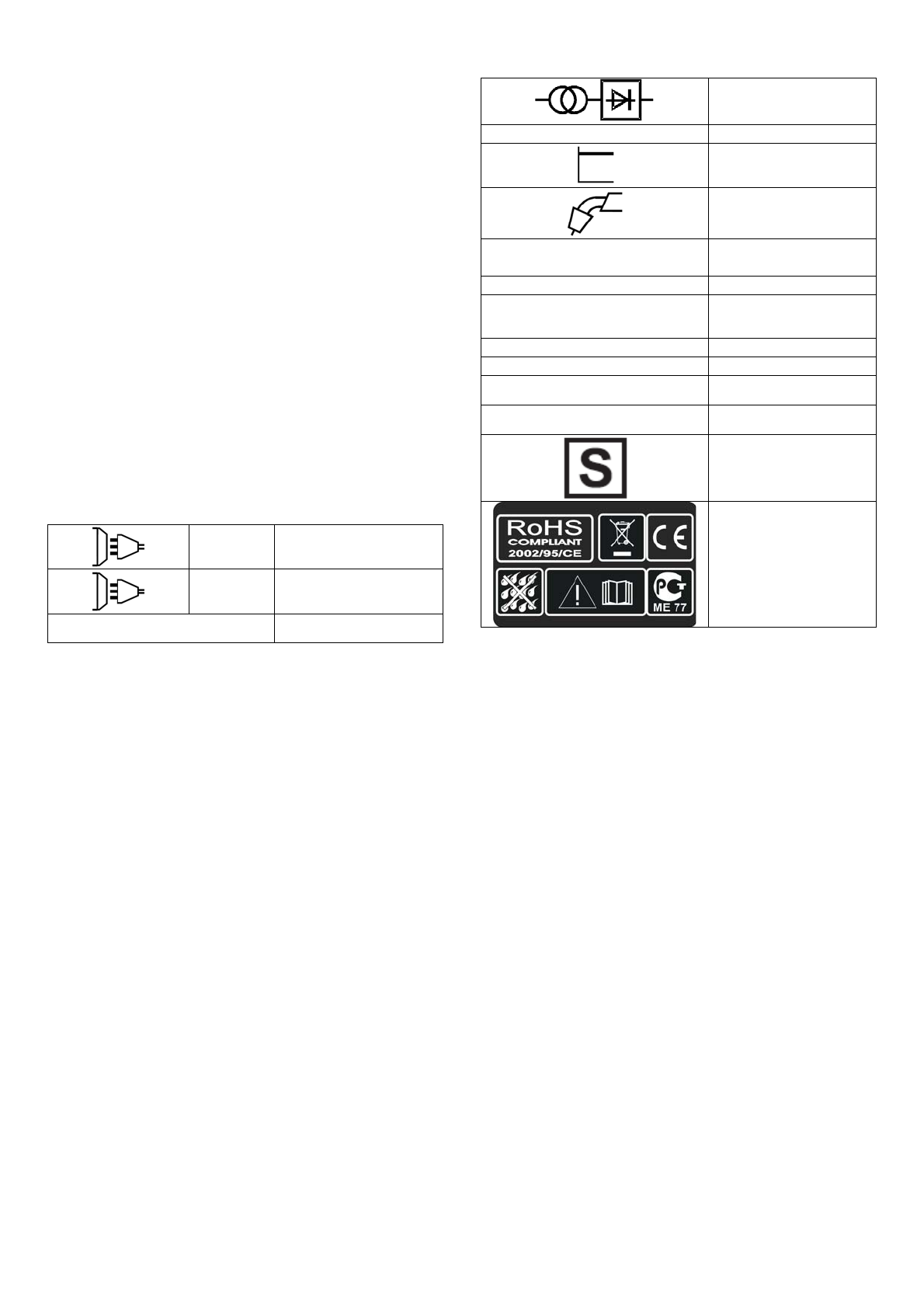

DESCRIPTION OF SIGNS AND SYMBOLS

1 ~

Single phase alternating

voltage

3 ~

Three phase alternating

voltage

U

0

… (V)

Nominal open circuit

voltage

Transformer-rectifier

EN 60974-1

Norm of reference

Flat characteristic

MIG-MAG wire feed

welding

U

1

… (V/Hz)

Nominal values of mains

voltage and frequency

I

2

… (A)

Welding current

I

1 max

(A)

The welding unit's

maximum absorbed

current

I

1 eff

… (A)

Effective current supplied

X

Duty cycle

IP21

The welding unit's

protection class

H

The transformer's

insulation class.

Welding machine suitable

for use in environments

with heightened risk of

electric shock.

Symbols referring to safety

regulations

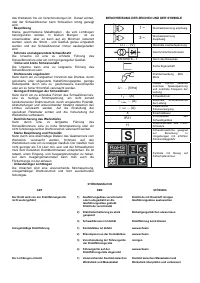

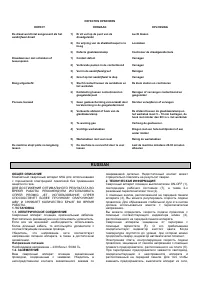

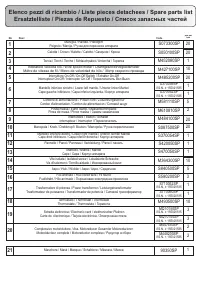

FAULT FINDING

FAULT

Wire isn’t conveyed when

Feed roll is turning

Wire feeding in jerk or

erratic way

No arc

Porous welding seams

The machine suddenly stops welding

operations after an extended and heavy

duty use

REASON

1) Dirt in liner and/or contact tip

2) The frition brake in the hub

is too tightened

3)

Faulty welding torch

1) Contact tip defect

2) Burns in contact tip

3) Dirt in feed roll groove

4)

Feed roll’s groove worn

1) Bad concat between earth clamp

and workpiece

2) Short-circuit between contact tip

and gas shroud

1) Failre of gas shield owing to

spatters in gas shro

2)

Wrong welding torch distance

and/or inclination from workpiece

3) Too small gas flux

4) Humid

workpieces

5) Heavily

rusted

workpieces

1) Welding machine overheated due

to an excessive use in stated duty

cycle

REMEDY

Blow with compressed air, replace contact

tip

Loosen

Check sheating of torchès

wire guide

Replace

Replace

Clean

Replace

Tighten earth clamp and check connections

Clean, replace tip and/or shroud as

necessary

Clean gas shroud from spatters

The length of stick out wire from tip must

be 5 – 10mm. Inclination not less than 60

degrees in relation to woekpiece

Increase flux of welding gas

Dry with heat producer

Clean workpieces from rust

Don’t switch off the machine, let it cool

down for about 20/30 minutes