Осушители воздуха Black+Decker BXDH20E - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

ENGLISH

(Original instructions)

7

The appliance contains flammable refrigerant.

For eu versions of the product and / Or if applicable in your country:

ecology and recyclability of the product

♦

The materials that constitute the packaging of this apparatus, are integrated in a

system of collection, classification and recycling of the same. If you want to dispose of

them, you can use the appropriate public containers for each type of material.

♦ The product is exempt from concentrations of substances which may be considered

harmful to the environment.

This symbol means that if you want to dispose of the product, after the end of

its life, you must deposit it by the appropriate means at the disposal of an

authorized waste manager for the selective collection of Waste Electrical and

Electronic Equipment (WEEE).

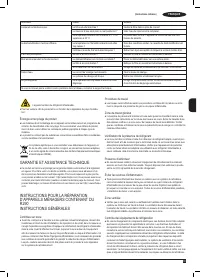

WARRANTY AND TECHNICAL ASSISTANCE

♦ This product enjoys the recognition and protection of the legal guarantee in accordance

with current legislation.

♦ To enforce your rights or interests you must go to any of our official technical assistan

-

ce services. You can find the closest one by accessing the following web link: http://

www.2helpu.com/ You can also request related information, by contacting us (see the

last page of the manual). You can download this instruction manual and its updates at

http://www.2helpu.com/

INSTRUCTIONS FOR REPAIRING APPLIANCES

CONTAINING R290

GENERAL INSTRUCTIONS

Checks to the area

♦ Prior to beginning work on systems containing flammable refrigerants, safety checks

are necessary to ensure that the risk of ignition is minimised. For repair to the refrige-

rating system, the following precautions shall be complied with prior to conducting work

on the system.

Work procedure

♦

Work shall be undertaken under a controlled procedure so as to minimise the risk of a

flammable gas or vapour being present while the work is being performed.

General work area

♦ All maintenance staff and others working in the local area shall be instructed on the

nature of work being carried out. Work in confined spaces shall be avoided. The area

around the workspace shall be sectioned off. Ensure that the conditions within the area

have been made safe by control of flammable material.

Checking for presence of refrigerant

♦ The area shall be checked with an appropriate refrigerant detector prior to and during

work, to ensure the technician is aware of potentially flammable atmospheres. Ensure

that the leak tection equipment being used is suitable for use with flammable refrige

-

rants, i.e. nonsparking, adequately sealed or intrinsically safe.

Presence of fire extinguisher

♦ If any hot work is to be conducted on the refrigeration equipment or any associated

parts, propriate fire extinguishing equipment shall be available to hand. Have a dry

powder or CO 2 fire extinguisher adjacent to the charging area.

No ignition sources

♦ No person carrying out work in relation to a refrigeration system which involves

exposing any pipe work that contains or has contained flammable refrigerant shall use

any sources of ignition in such a manner that it may lead to the risk of fire or explosion.

All possible ignition sources, including igarette smoking, should be kept sufficiently

far away from the site of installation, repairing, removing and disposal, during which

flammable refrigerant can possibly be released to the surrounding space. Prior to work

taking place, the area around the equipment is to be surveyed to make sure that there

are no flammable hazards or ignition risks. “No Smoking” signs shall be displayed.

Ventilated area

♦ Ensure that the area is in the open or that it is ade- quately ventilated before breaking

into the system or conducting any hot work. A degree of ventilation shall continue

during the period that the work is carried out. The ventilation should safely disperse any

released refrigerant and preferably expel it externally into the atmosphere.

Checks to the refrigeration equipment

♦ Where electrical components are being changed, they shall be fit for the purpose

and to the correct specification. At all times the manufacturer’s mainte- nance and

service guidelines shall be followed. If in doubt consult the manufacturer’s technical

department for assistance.The following checks shall be applied to installations using

flammable refrigerants: the charge size is in accordance with the room size within

which the refrigerant containing parts are installed; the ventilation machinery and out

-

lets are operating adequately and are not obstructed; if an indirect refrigerating circuit

is being used, the secondary circuit shall be checked for the presence of refrigerant;

marking to the equipment continues to be visible and legible. Markings and signs that

are illegible shall be corrected; refrigeration pipe or components are installed in a

position where they are unlikely to be exposed to any substance which may corrode

refrigerant containing components, unless the components are constructed of materials

which are inherently resistant to being corroded or are suitably protected against being

so corroded.

Checks to electrical devices

♦

Repair and maintenance to electrical components shall include initial safety checks and

component inspection procedures. If a fault exists that could compromise safety, then

no electrical supply shall be connected to the circuit until it is satisfactorily dealt with. If

the fault cannot be corrected immediately but it is necessary to continue operation, an

adequate temporary solution shall be used. This shall be reported to the owner of the

equipment so all parties are advised.

♦

Initial safety checks shall include: that capacitors are discharged: this shall be done in

a safe manner to avoid possibility of sparking; that there no live electrical components

and wiring are exposed while charging, recovering or purging the system; that there is

continuity of earth bonding.

REPAIRS TO SEALED COMPONENTS

♦

During repairs to sealed components, all electrical supplies shall be disconnected from

the equipment being worked upon prior to any removal of sealed covers, etc. If it is

absolutely necessary to have an electrical supply to equipment during servicing, then a

permanently operating form of leak detection shall be located at the most critical point

to warn of a potentially hazardous situation.

♦ Particular attention shall be paid to the following to ensure that by working on electrical

components, the casing is not altered in such a way that the level of protection is

affected.

♦ This shall include damage to cables, excessive number of connections, terminals not

made to original specification, damage to seals, incorrect fitting of glands, etc. Ensure

that apparatus is mounted securely. Ensure that seals or sealing materials have not

degraded such that they no longer serve the purpose of preventing the ingress of flam

-

mable atmospheres. Replacement parts shall be in accordance with the manufacturer’s

specifications.

♦ NOTE The use of silicon sealant may inhibit the effectiveness of some types of leak

detection equipment. Intrinsically safe components do not have to be isolated prior to

working on them.

REPAIR TO INTRINSICALLY SAFE COMPO- NENTS

♦ Do not apply any permanent inductive or capacitance loads to the circuit without

ensuring that this will not exceed the permissible voltage and current permitted for the

equipment in use. Intrinsically safe components are the only types that can be worked

on while live in the presence of a flammable atmosphere. The test apparatus shall be

at the correct rating. Replace com- ponents only with parts specified by the manufactu

-

rer. Other parts may result in the ignition of refrigerant in the atmosphere from a leak.

CABLING

♦ Check that cabling will not be subject to wear, corrosion, excessive pressure, vibration,

sharp edges or any other adverse environmental effects. The check shall also take into

account the effects of aging or continual vibration from sources such as compressors

or fans.

DETECTION OF FLAMMABLE REFRIGE- RANTS

♦

Under no circumstances shall potential sources of ignition be used in the searching for

or detection of refrigerant leaks. A halide torch (or any other detector using a naked

flame) shall not be used.

Характеристики

Остались вопросы?Не нашли свой ответ в руководстве или возникли другие проблемы? Задайте свой вопрос в форме ниже с подробным описанием вашей ситуации, чтобы другие люди и специалисты смогли дать на него ответ. Если вы знаете как решить проблему другого человека, пожалуйста, подскажите ему :)