Бензопилы Partner P350S 9666991-01 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

-- 12 --

NOTE:

For efficient operation of saw engine,

spark plug must be kept clean and properly

gapped.

1. Push STOP switch down.

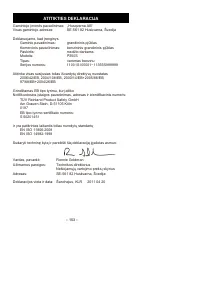

2. Remove knob (A) holding air filter cover in

place, remove the top cover (B) by

loosening the cover retaining screws.

Cover will lift off. (Fig.18A)

3. Disconnect the wire connector (C) from the

spark plug (D) by pulling and twisting at the

same time (Fig. 18B).

4. Remove spark plug with spark plug socket

wrench. DO NOT USE ANY OTHER

TOOL.

5. Check electtrode gaps with wire feeler

gauge and set gaps to .025” (.635mm) if

necessary.

6. Reinstall a new spark plug.

NOTE:

A resistor spark plug must be used for

replacement.

NOTE:

This spark ignition system meets all

requirements of the Interference-Causing

Equipment Regulations.

1. Remove spark plug.

2. Pull starter rope briskly to clear excess oil

from combustion chamber.

3. Clean and gap spark plug or install a new

spark plug with proper gap.

4. Prepare unit for operation.

5. Fill fuel tank with proper fuel / oil mixture.

See

FUEL AND LUBRICATION

Section.

Frequent lubrication of the guide bar (railed

bar which supports and carries the saw

chain) sprocket tip is required. Proper

maintenance of the guide bar, as explained in

this section, is essential to keep your saw in

good working condition.

Lubrication

of

the

sprocket

tip

is

recommended after 10 hours of use or once

a week, which ever occurs first. Always

thoroughly clean guide bar sprocket tip

before lubrication.

The Lube Gun (optional) is recommended for

applying grease to the guide bar sprocket tip.

The Lube Gun is equipped with a needle

nose tip which is necessary for the efficient

application of grease to the sprocket tip.

Storing a chain saw for longer than 30 days

requires storage maintenance. Unless the

storage instructions are followed, fuel

remaining in the carburetor will evaporate,

leaving gum-like deposits. This could lead to

difficult starting and result in costly repairs.

1. Remove the fuel tank cap slowly to release

any pressure in tank. Carefully drain the

fuel tank.

2. Start the engine and let it run until the unit

stops to remove fuel from carburetor.

3. Allow the engine to cool (approx. 5

minutes).

4. Using a spark plug wrench, remove the

spark plug.

1. Press the STOP switch down.

NOTE:

It is not necessary to remove the saw

chain to lubricate the guide bar sprocket tip.

Lubrication can be done on the job.

2. Clean the guide bar sprocket tip.

3. Using the Lube Gun (optional), insert

needle nose into the lubrication hole and

inject grease until it appears at outside

edge of sprocket tip (Fig. 20).

CAUTION:

Never store a chain saw

for longer than 30 days without performing

the following procedures.

The carburetor was preset at the factory for

optimum performance. If further adjustments

are necessary, please take your unit to the

nearest qualified service technician.

WARNING:

Wear heavy duty work

gloves when handling the bar and chain.

CAUTION:

The sprocket tip on your

new saw has been pre-lubricated at the

factory. Failure to lubricate the guide bar

sprocket tip as explained below will result in

poor performance and seizure, voiding the

manufacturer’s warranty.

Fig. 17A

A

Fig. 17B

B

C

B

B

D

SPARK PLUG

Fig. 18A

A

Fig. 18B

C

D

B

CARBURETOR ADJUSTMENT

STORING A CHAIN SAW

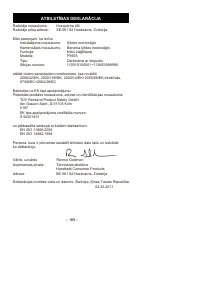

5. Pour 1 teaspoon of clean 2-cycle oil into

the combustion chamber. Pull starter rope

slowly several times to coat internal

components. Replace spark plug. (Fig. 19)

NOTE:

Store the unit in a dry place and away

from possible sources of ignition such as a

furnace, gas hot water heater, gas dryer, etc.

Fig. 19

REMOVING A UNIT FROM STORAGE

GUIDE BAR MAINTENANCE

SPROCKET TIP LUBRICATION:

TOOLS FOR LUBRICATION:

TO LUBRICATE SPROCKET TIP:

Содержание

- 2 ИНСТРУКЦИЯ ПО ЭКСПЛУАТАЦИИ; ВАЖНАЯ ИНФОРМАЦИЯ; INSTRUCTION MANUAL; IMPORTANT INFORMATION; ANVÄNDARHANDBOK; VIKTIG INFORMATION; BRUKERHÅNDBOK; VIKTIG INFORMASJON; BRUGERHÅNDBOG; VIGTIGE OPLYSNINGER; KÄYTTÖOHJEKIRJA; TÄRKEÄÄ; INSTRUKCJA OBSŁUGI; WAZNE INFORMACJE; NÁVOD K POUŽĺVÁNĺ; DŮLEŽITÁ INFORMACE; KASUTUSJUHEND; TÄHTIS INFO; EE; LIETOŠANAS PAMĀCĪBA; SVARĪGA INFORMĀCIJA; INSTRUKCIJŲ VADOVAS; SVARBI INFORMACIJA

- 18 ПРЕДОХРАНИТЕЛЬНЫЕ ДЕТАЛИ

- 19 ПРАВИЛА ТЕХНИКИ БЕЗОПАСНОСТИ

- 21 ЗНАЧЕНИЕ СИМВОЛОВ И ЦВЕТОВОЙ; ПРЕДУПРЕЖДЕНИЕ; ИНСТРУМЕНТЫ ДЛЯ СБОРКИ

- 22 УСТАНОВКА ПИЛЬНОЙ ЦЕПИ; РЕГУЛИРОВКА НАТЯЖЕНИЯ; УСТАНОВКА НАПРАВЛЯЮЩЕЙ ШИНЫ,; РЕГУЛИРОВКА

- 23 ТОПЛИВО И СМАЗКА; ТАБЛИЦА ТОПЛИВНЫХ СМЕСЕЙ; МЕХАНИЧЕСКОЕ ИСПЫТАНИЕ; ПРОЦЕДУРА ИСПЫТАНИЯ ТОРМОЗА; ТОПЛИВО

- 24 ЭКСПЛУАТАЦИЯ

- 26 ОБЩИЕ ИНСТРУКЦИИ ПО ПИЛЕНИЮ; ВАЛКА ДЕРЕВЬЕВ

- 27 ИНСТРУКЦИИ ПО ТЕХНИЧЕСКОМУ ОБСЛУЖИВАНИЮ; ВРЕМЯ; КОНТРОЛЬНЫЙ СПИСОК; ОБРЕЗКА ВЕТОК; ВЕРТИКАЛЬНОЕ ПИЛЕНИЕ

- 28 ПРОЦЕДУРА ОЧИСТКИ

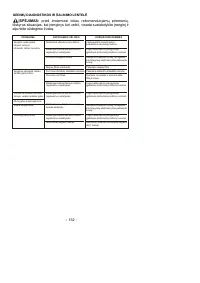

- 31 ИЗНОС ШИНЫ; Всегда выключайте инструмент и отсоединяйте свечу; ТАБЛИЦА СПОСОБОВ УСТРАНЕНИЯ НЕПОЛАДОК

- 32 ДЕКЛАРАЦИЯ О СООТВЕТСТВИИ СТАНДАРТАМ

- 33 ТЕХНИЧЕСКИЕ ХАРАКТЕРИСТИКИ