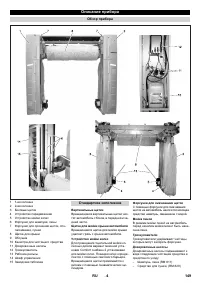

Мойки высокого давления Karcher CB 1 28 Eco - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

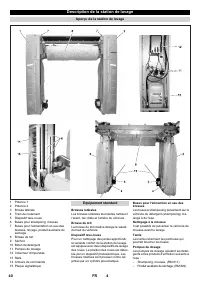

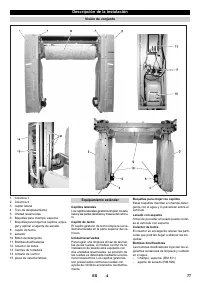

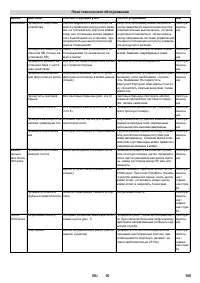

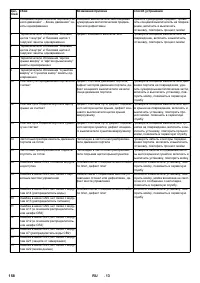

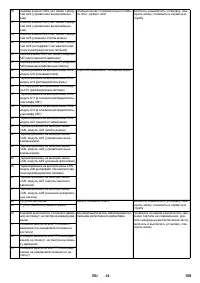

-

6

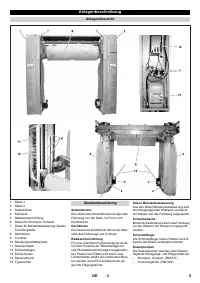

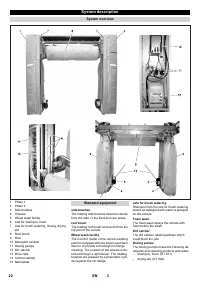

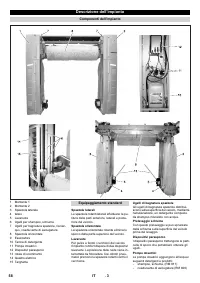

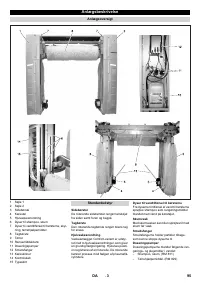

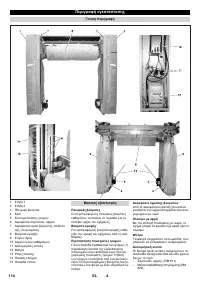

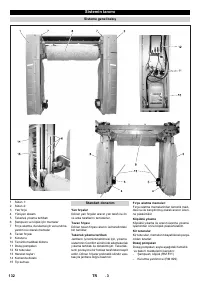

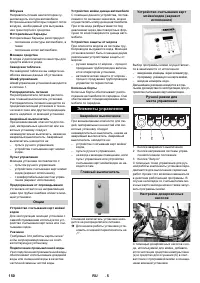

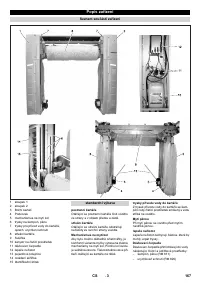

Drive in the vehicle between the driving

tracks and position the left front wheel

in the wheel trough.

switch off engine.

Put gear in. Choose position “P2” with

automatic gearbox.

Pull up handbrake.

Check whether the directions in the

"Preparing the vehicle" section have

been followed.

Leave vehicle (all occupants) and start

wash programme.

The operation with a wash card/code read-

er is described in the separate operating in-

structions for the wash card/code reader.

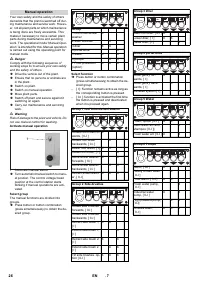

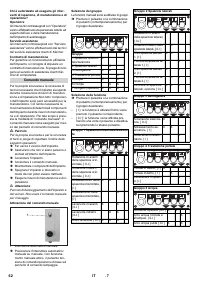

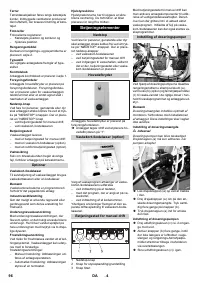

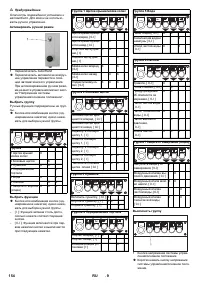

Press one or several buttons to start the

desired wash programme. (see follow-

ing table

Press Start key.

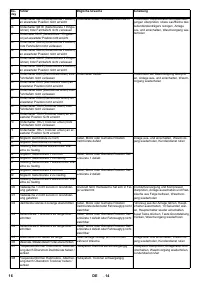

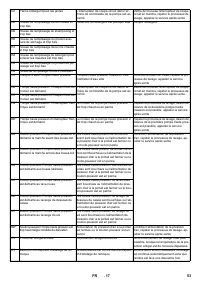

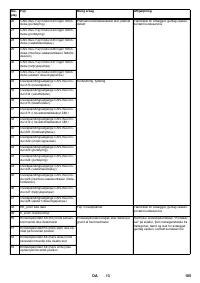

When the wash programme is in progress,

the brushes can be moved away from the

vehicle (travel out) or locked (to prevent fur-

ther travel towards the car). The wheel

wash can also be deactivated once the

washing operation has started.

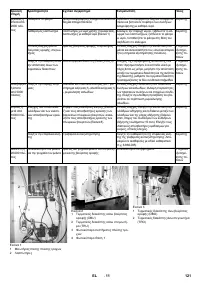

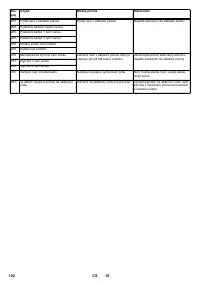

1 Raise/lock roof brush or drier

2 Move out/lock side brushes

3 Deactivate wheel wash

4 Trigger stop

When the wash programme is ended, the

vehicle can be driven out of the plant.

The hall doors are controlled by the car wash

gantry control and by an external door control.

Difference is made between summer and win-

ter door control.

–

Before the start of the wash, the doors are

open. The vehicle can drive in.

–

The doors are closed at the start of the

wash.

–

The doors are opened at the end of the

wash and stay open.

–

Before the start of the wash, the entry

gate is closed and must be opened to

allow the vehicle to drive in. This can be

done, for example, by inserting a card

into the wash card reader.

–

When the wash starts (e.g. when the

"start" button on the wash card reader is

pressed), the entry gate closes.

–

The doors are opened at the end of the

wash and are closed again after the ve-

hicle has driven out.

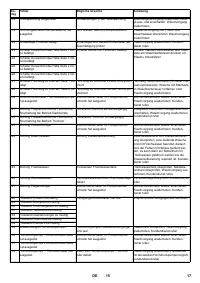

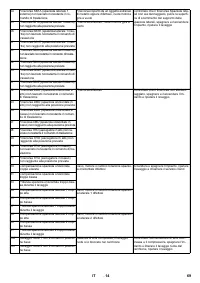

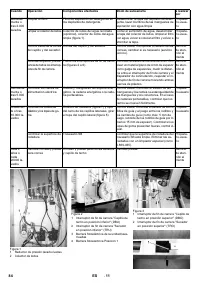

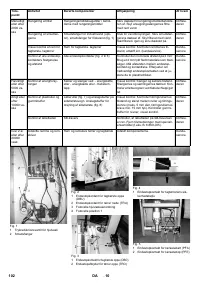

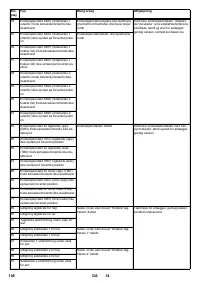

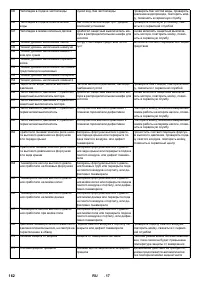

End running wash programme.

Set main switch to “O”.

End running wash programme.

Set main switch to “O”.

Shut off water supply.

Shut off compressed air line.

If frost is expected for the period of the

shutdown:

dewater all water pipelines.

몇

Warning

Risk of damage to the the plant. The anti-

frost device functions only when the main

switch is on and the emergency-stop but-

tons are not pressed.

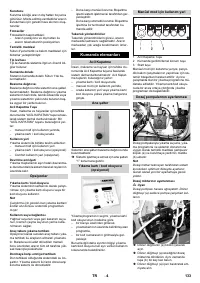

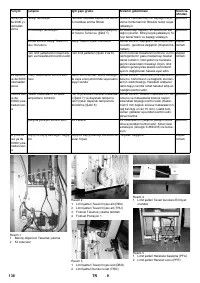

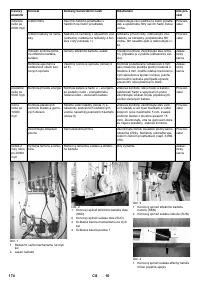

Manual valves and switch “Anti-frost Manu-

al“ are found in the technician room.

Close manual valve for fresh water and

processed water (option).

Release compressed air for anti-frost

by opening the manual valve in the

compressed air line.

Activate “Anti-frost Manual”, which

starts the blow-out procedure.

Close manual valve compressed air for

anti-frost after the blow-out procedure

has ended.

When putting into operation for the first

time after manual antifrost, close the man-

ual valves for fresh water and processed

water (option).

If the minimum temperature is undercut:

–

any wash operation which is in progress

is completed.

–

the gantry hoses and jet pipes are

blown out with compressed air

–

No more wash programme can be started.

Should the anti-frost measures be intro-

duced with automatic anti-frost as a pre-

caution when the plant is shut down, an

additional switch can be installed by the

factory.

Once the danger of frost has passed, the

plant automatically resumes a state of op-

erational readiness.

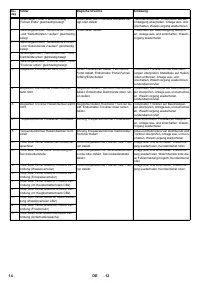

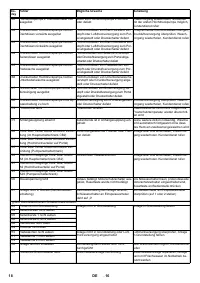

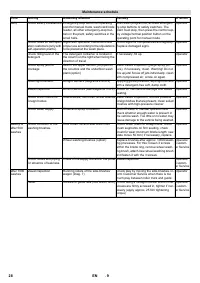

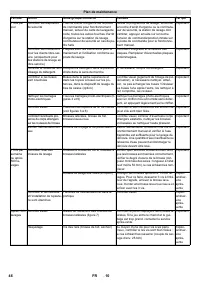

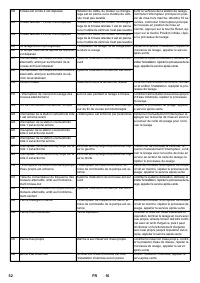

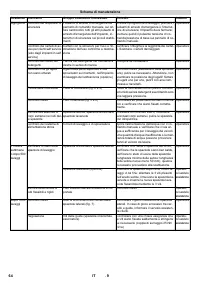

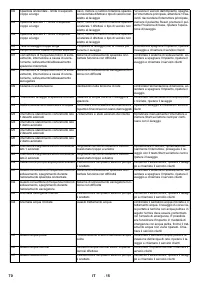

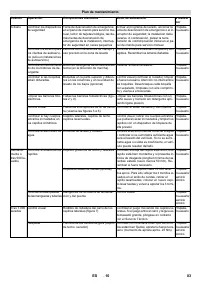

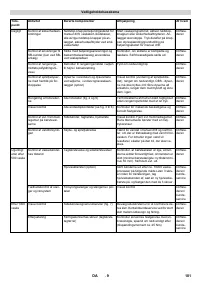

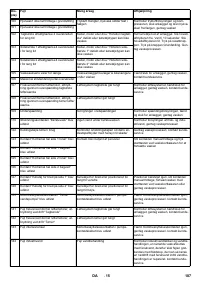

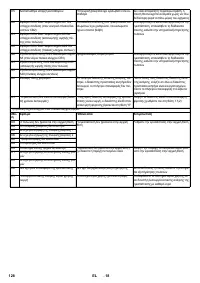

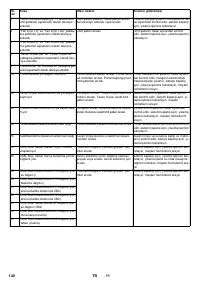

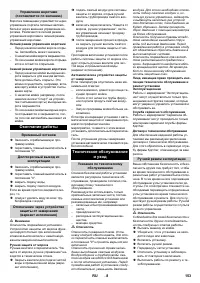

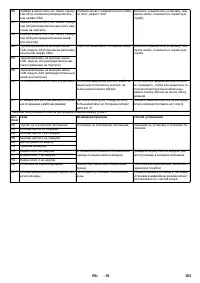

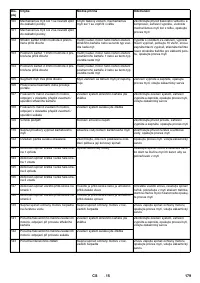

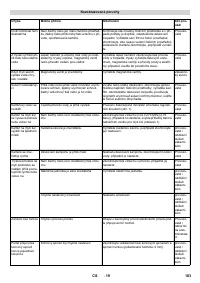

The basis for a safe operational plant is the

regular maintenance according to the fol-

lowing maintenance plan

Use exclusively original parts of the manu-

facturer or those parts recommended by

him like

–

replacement and wear parts

–

accessory parts

–

fuel,

–

detergents.

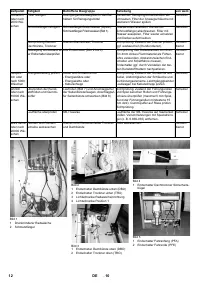

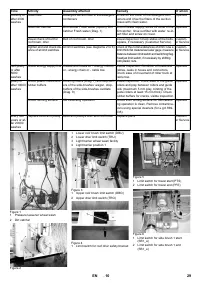

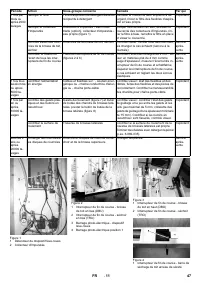

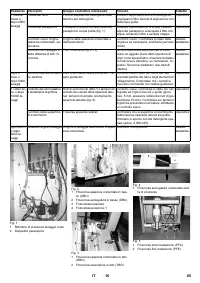

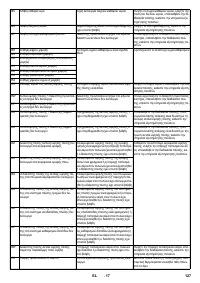

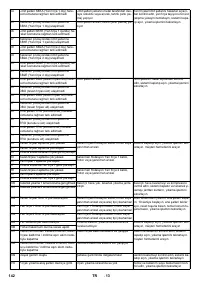

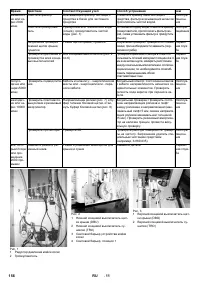

Danger

Risk of electric shock. Switch on the plant

voltage-free, in addition switch on the main

switch to “0” and secure against it switching

on again.

Risk of injury from compressed air unex-

pectedly emerging. Compressed-air cylin-

ders and lines also remain under pressure

after the plant has been switched off. It is

absolutely necessary to get rid of pressure

before starting work on the plant. To do

this, turn off the compressed air supply and

move the wheel wash system in and out in

manual mode to release the pressure.

Then check for the absence of pressure on

the manometer at the maintenance unit.

Risk of injury from high-pressure water jet unex-

pectedly emerging. It is absolutely necessary to

remove all pressure in the high-pressure sys-

tem before starting work on the plant.

Risk of eye injuries from parts flying off or dirt.

Keep clear of rotating brushes. Goggles must

be worn during maintenance work.

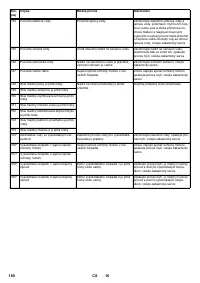

Operator

Work designated with the sign “Operator”

may only be carried out by persons who

have been instructed in the safe operation

and maintenance on the wash plant

Customer Service

Work designated with the sign “Customer

Service” may only be done by the fitters of

Kärcher Customer Service.

In order to ensure a reliable operation of the

plant, we recommend that you conclude a

maintenance contract with us. Please con-

tact your relevant Kärcher Customer Serv-

ice.

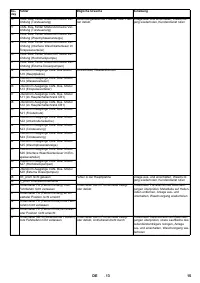

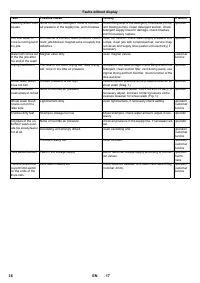

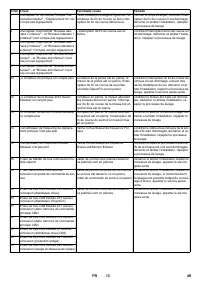

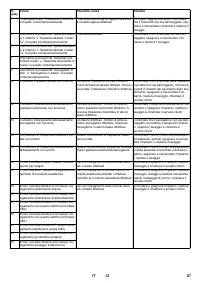

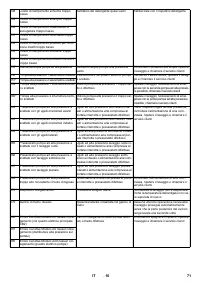

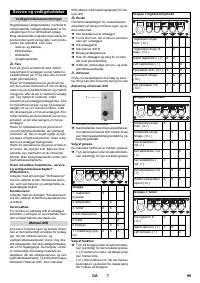

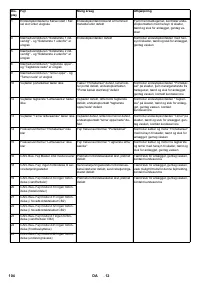

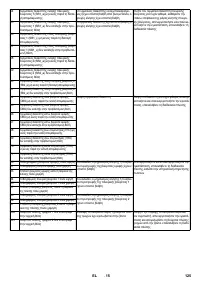

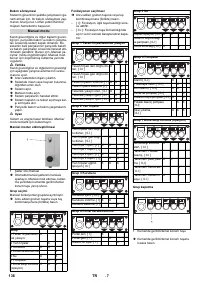

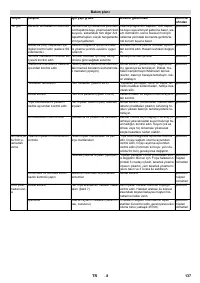

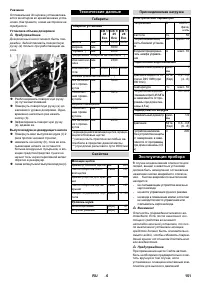

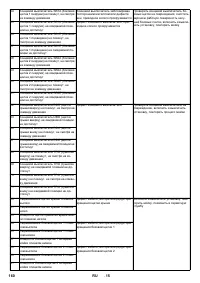

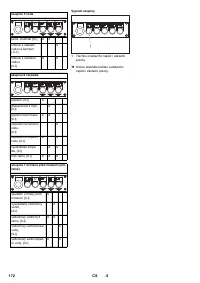

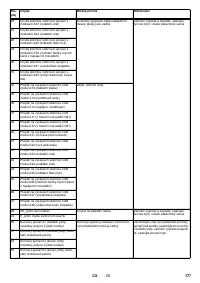

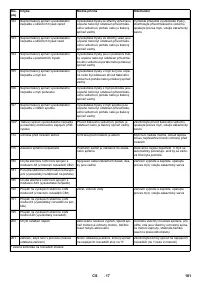

Driving in the vehicle

After the positioning

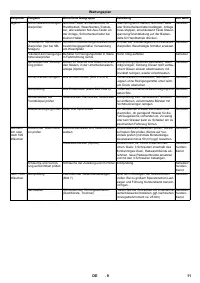

Start program

at the wash card/code reader (option)

with control station for manual operation

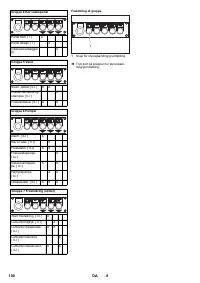

Program

1

X

2

X

3

X

X

4

X

5

X

X

6

X

X

7

X

X

X

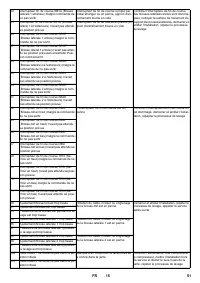

Manual intervention

Program end

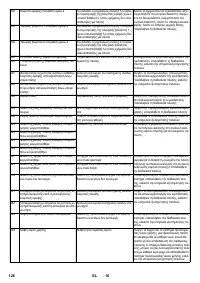

Door control (option)

Summer door control

Winter door control

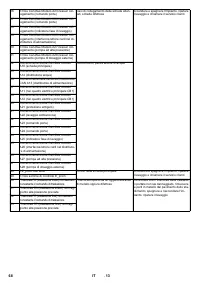

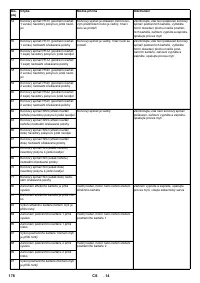

Shutting down

Brief shutting down

Decommissioning for longer

periods

Shutting down through anti-freeze

device (option)

Manual anti-frost device

Automatic anti-frost device

Maintenance and care

Maintenance instructions

Who may carry out maintenance and

servicing?

Maintenance contract

25

EN