Электропилы Bosch GKS 160 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

English |

19

1 609 929 J94 • 6.11.06

Note:

To be accurate, an estimation of the level of

exposure to vibration experienced during a given

period of work should also take into account the times

when the tool is switched off and when it is running

but not actually doing the job. This may significantly

reduce the exposure level over the total working

period.

Declaration of Conformity

We declare under our sole responsibility that this

product is in conformity with the following standards

or standardization documents: EN 60745 according

to the provisions of the directives 89/336/EEC,

98/37/EC.

11.10.2006, Robert Bosch GmbH, Power Tools Division

D-70145 Leinfelden-Echterdingen

Assembly

Mounting/Replacing the Saw Blade

f

Before any work on the machine itself, pull

the mains plug.

f

When mounting the saw blade, wear protec-

tive gloves.

Danger of injury when touching the

saw blade.

f

Only use saw blades that correspond with

the characteristic data given in the operating

instructions.

f

Do not under any circumstances use grind-

ing discs as the cutting tool.

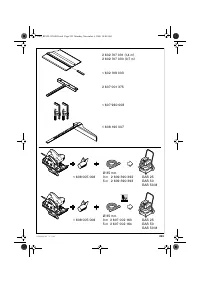

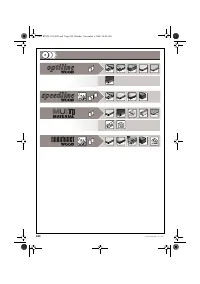

Selecting a Saw Blade

An overview of recommended saw blades can be

found at the end of this manual.

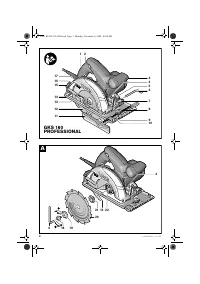

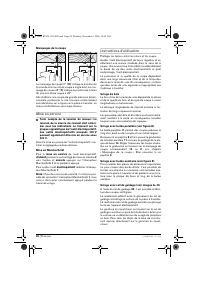

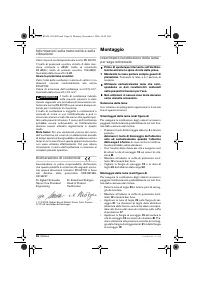

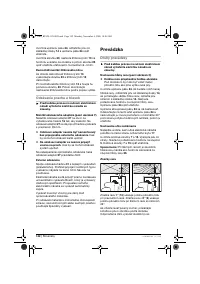

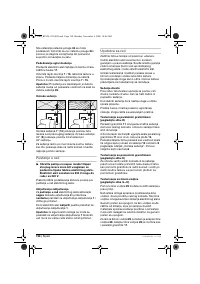

Removal of the Saw Blade (see figure A)

For changing the cutting tool, it is best to place the

machine on the face side of the motor housing.

•

Press the spindle lock button

4

and keep it

pressed.

The spindle lock button 4 may be actuated

only when the saw spindle is at a standstill.

Otherwise, the power tool can be damaged.

•

With the Allen key

6

, unscrew the clamping bolt

18

turning in rotation direction

n

.

•

Tilt back the retracting blade guard

12

and hold

firmly.

•

Remove the clamping flange

19

and the saw blade

20

from the saw spindle

22

.

Mounting the Saw Blade (see figure A)

For changing the cutting tool, it is best to place the

machine on the face side of the motor housing.

•

Clean the saw blade

20

and all clamping parts to

be assembled.

•

Tilt back the retracting blade guard

12

and hold

firmly.

•

Place the saw blade

20

on to the mounting flange

21

. The cutting direction of the teeth (direction or

arrow on saw blade) and the direction-of-rotation

arrow on the blade guard

17

must correspond.

•

Mount the clamping flange

19

and screw in the

clamping bolt

18

turning in rotation direction

o

.

Observe correct mounting position of mounting

flange

21

and clamping flange

19

.

•

Press the spindle lock button

4

and keep it

pressed.

•

With the Allen key

6

, tighten the clamping bolt

18

turning in rotation direction

o

. The tightening

torque is between 6 – 9 Nm, which corresponds to

hand tight plus ¼ turn.

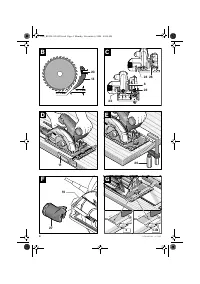

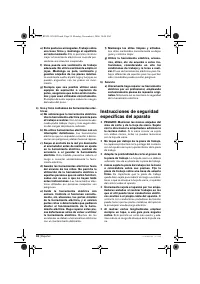

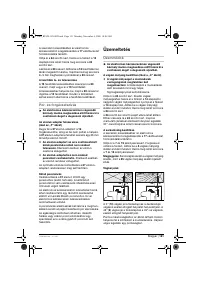

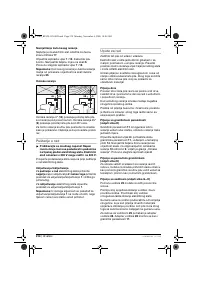

Adjusting the Riving Knife

(see figure B – C)

f

Before any work on the machine itself, pull

the mains plug.

f

Always work with the riving knife, except

when carrying out plunge cuts.

The riving knife

prevents jamming of the saw blade while sawing.

Adjustment is carried out at minimal cutting depth,

see “Adjusting the Cutting Depth”, page 20.

It is best to place the machine on the face side of the

blade guard

17

.

Loosen the clamping lever

24

, pull the saw away from

the base plate

14

and then tighten the clamping lever

24

again.

Loosen screw

23

, adjust the riving knife

13

to the

measure shown in the figure and tighten screw

23

with a tightening torque between 8 – 9 Nm.

Disassembly/Assembly of the Riving Knife

For disassembly of the riving knife

13

, unscrew the

screw

23

and remove the riving knife

13

.

For assembly, insert the riving knife

13

and tighten it

with the screw

23

. Afterwards, check the adjustment

of the riving knife as described previously.

Dr. Egbert Schneider

Senior Vice President

Engineering

Dr. Eckerhard Strötgen

Head of Product

Certification

OBJ_BUCH-185-002.book Page 19 Monday, November 6, 2006 10:08 AM