Шуруповерты VERTO 50G852 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

8

TRANSLATION OF THE ORIGINAL INSTRUCTIONS

IMPACT DRILL

50G852

CAUTION: BEFORE USING THE POWER TOOL READ THIS MANUAL

CAREFULLY AND KEEP IT FOR FUTURE REFERENCE.

DETAILED SAFETY REGULATIONS

• Use ear protectors when operating impact drill.

Noise hazards may

cause hearing loss.

• Use additional handles supplied with the tool.

Loss of control may

cause operator personal injury.

Description of improper use

Do not throw the tool, do not overload, do not immerse in water or other

fluids, do not use for mixing adhesive or cement mortars, do not hang,

carry, pull or unplug the power tool by pulling the cord. Avoid using long

extension cords.

Accessories that you can use

Wood, metal and masonry drills, grinding discs and wire brushes (wear

safety goggles when using grinding discs and wire brushes).

CAUTION! This device is designed to operate indoors.

The design is assumed to be safe, protection measures and

additional safety systems are used, nevertheless there is always a

small risk of operational injuries.

CONSTRUCTION AND USE

Impact drills are hand operated power tools with insulation class II. Tools

are driven by single-phase commutator motors with rotational speed

reduced with gear transmission. This type of power tools is widely used

for making holes in wood, wood-like materials, metals, ceramics and

plastics (rotation only), and concrete, bricks and alike (with impact).

Range of use covers repair and building works, woodworking and any

work from the scope of individual, amateur activities (tinkering).

Use the power tool according to the manufacturer’s instructions only.

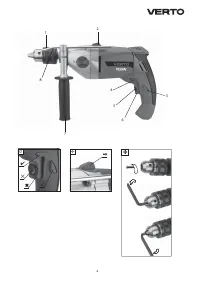

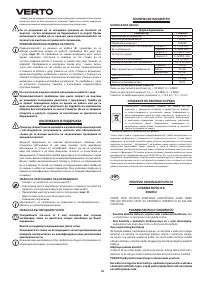

DESCRIPTION OF DRAWING PAGES

Below enumeration refers to the device elements depicted on the

drawing pages of this manual.

1.

Drill chuck

2.

Operation mode switch

3.

Switch lock button

4.

Direction selector switch

5.

Wheel for rotational speed control

6.

Switch

7.

Additional handle

8.

Depth gauge rod

9.

Gear switch

* Slight differences may appear between the product and drawing

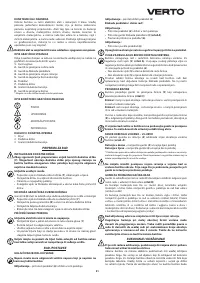

MEANING OF SYMBOLS

CAUTION

WARNING

ASSEMBLY/SETTINGS

INFORMATION

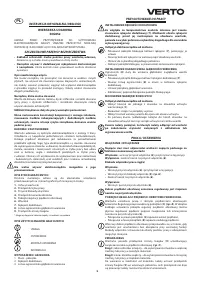

EQUIPMENT AND ACCESSORIES

1. Key - handwheel

2

. Additional

handle

3

. Depth gauge rod

PREPARATION FOR OPERATION

INSTALLATION OF ADDITIONAL HANDLE

Due to personal safety issues it is recommended to always use the

additional handle (7). Possibility to rotate the additional handle

before it is clamped on the drill body allows choosing the position

most comfortable for specific working conditions.

GB

Disconnect the power tool from power supply.

•

Loosen the wheel lock that locks collar of the locking handle (

7

) by

turning it counter-clockwise.

•

Slide the handle collar over cylindrical part of the drill body.

•

Turn for the most comfortable position.

•

Turn the wheel lock clockwise tightly to clamp the handle.

DEPTH GAUGE INSTALLATION

Depth gauge

(8)

serves to limit the depth of drill penetration of material

•

Loosen the wheel lock, which blocks collar of the additional handle

(

7

).

•

Slide depth gauge rod (

8

) into the hole in the additional handle collar.

•

Set desired drill depth.

•

Fix by tightening the wheel lock.

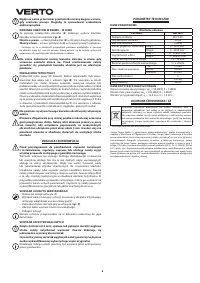

INSTALLATION OF WORKING TOOLS

Disconnect the power tool from power supply.

•

Insert key into one of the holes on the side wall of the drill chuck (

1

).

•

Open jaws to desired dimension.

•

Insert cylindrical drill shank into the chuck, push it to the limit.

•

Tighten jaws on drill shank with the key (insert it into three holes on

the chuck side wall).

Remember to always remove the key from the chuck after you finish

drill installation or removal.

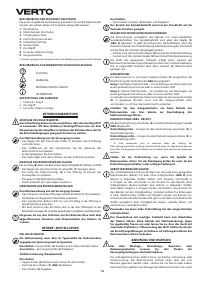

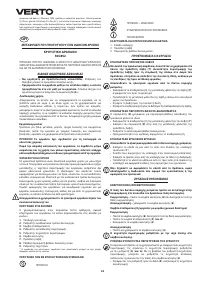

OPERATION / SETTINGS

SWITCHING ON / SWITCHING OFF

The mains voltage must match the voltage on the rating plate of

the drill.

Switching on

– press the switch button (

6

) and hold in this position.

Switching off

– release pressure on the switch (

6

).

Locking the switch (continuous operation)

Switching on:

•

Press the switch button (

6

) and hold in this position.

•

Press the switch lock button (

3

)

(fig. A)

.

•

Release pressure on the switch (

6

).

Switching off:

•

Press and release the switch (

6

).

Range of rotational speed of the spindle is controlled with pressure

on the switch button.

WHEEL FOR SPINDLE ROTATIONAL SPEED CONTROL

Drill allows for operation with different spindle speeds. It can be

controlled with the wheel (

5

)

(fig. A)

. For each setting of the wheel for

speed control, the speed can be adjusted continuously by increasing or

decreasing pressure on the switch button (

6

).

•

Increase the speed by turning the wheel (

5

) clockwise.

•

Reduce the speed by turning the wheel (

5

) counter-clockwise.

Choose appropriate rotational speed when the drill operates with no

load, with pressed switch lock button. Speed that is set in this way may

decrease under load.

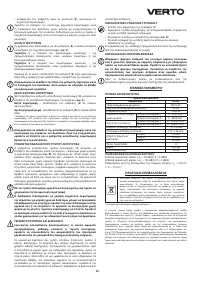

CHANGE OF GEAR

Drill is equipped with gear switch (

9

), which broadens the range of

rotational speed (

fig. C

).

Gear I

: lower range of rotational speeds – for large diameter holes or for

works with hard material.

Gear II

: higher range of rotational speeds – for small diameter holes or

for works with soft material.

Set the gear switch (

9

) in appropriate position depending on the

processed material. Turn the spindle slightly if the switch cannot be

moved.

Never change the switch position under operation of the drill. It

may damage the power tool.

LEFT – RIGHT DIRECTION OF ROTATION

Choose direction of spindle rotation with the selector switch (

4

) (

fig. A

).

Right rotation –

move the switch (

4

) to the extreme left position.

Left rotation –

move the switch (

4

) to the extreme right position.

* The possibility is reserved that in certain cases position of the switch relating to

rotation direction may be different than specified. Please refer to graphic signs placed

on the switch or tool body.

Do not change direction of rotation when the spindle of the drill is

rotating. Check if the position of the selector switch is correct before

starting the tool.