Заточные станки Metabo DS 150 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

ENGLISH

en

11

clean the inside of the grinding wheels and belt

grinder housing. The grinding wheels and sanding

belt must be able to rotate freely within the housing.

Unplug when the grinder is not in use, before

making any adjustments or carrying out

modifications, repairs or maintenance.

Regularly check the power cable on the grinder and

have it repaired by an approved expert if damaged.

Regularly check extension cables and replace if

damaged.

Check the grinder for possible damage: Before

using the grinder, protective devices or slightly

damaged components must be carefully checked to

ensure they are operating perfectly and as

intended. Check that moving parts are in perfect

working order and do not jam and check whether

parts are damaged. All parts must be correctly

installed and fulfil all conditions necessary to ensure

perfect operation of the grinder. Damaged

protective devices and parts must be repaired or

replaced according to specifications by an

authorised specialist workshop.

Reduce dust exposure:

Particles generated when working with this

machine may contain substances that can

cause cancer, allergic reactions, respiratory

diseases, birth defects or other propagation

defects. Some of these substances include: Lead

(in paint containing lead), mineral dust (from bricks,

concrete etc.), additives used for wood treatment

(chromate, wood preservatives), some wood types

(such as oak or beech dust), metals, asbestos.

The risk depends on for how long the user or nearby

persons are exposed to the substance.

This dust must not be allowed to enter your body.

Do the following to reduce exposure to these

substances: Ensure good ventilation of the

workplace and wear appropriate protective

equipment, such as respirators able to filter

microscopically small particles.

Observe the relevant guidelines for your material,

staff, application and place of application (e.g.

occupational health and safety regulations,

disposal).

Collect the generated particles at the source, avoid

deposits in the surrounding area.

Use suitable accessories for special work (see

chapter 9.), thus less particles enter the

environment in an uncontrolled manner.

Use a suitable extraction unit.

Reduce dust exposure with the following measures:

- Use an extraction unit and/or air purifiers

- Ensure good ventilation of the workplace and

keep clean using a vacuum cleaner Sweeping or

blowing stirs up dust

- Vacuum or wash the protective clothing Do not

blow, beat or brush

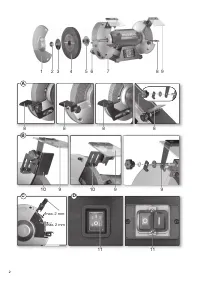

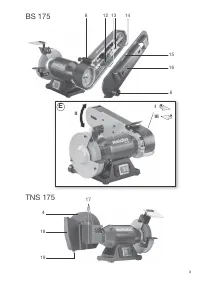

See page 2 and page 3.

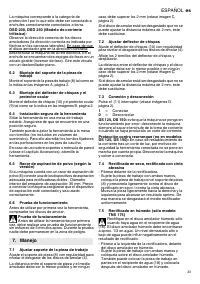

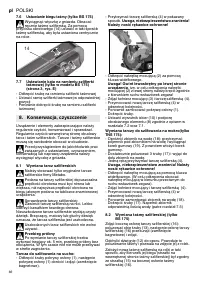

1 Safety cover

2 Adjusting nut

3 Clamping flange

4 Grinding wheel

5 Back flange

6 Dust extraction connection

7 Safety cover

8 Workpiece support

9 Eye preservers

10 Spark deflector

11 Switch (on/off)

12 Lever (sanding belt replacement) *

13 Screws for securing the sanding belt cover *

14 Rotary knob for adjusting the belt run *

15 Arrow (direction of circulation of sanding belt)*

16 Sanding belt cover *

17 Screws for securing the water container *

18 Water container *

19 Rubber stopper *

* depending on equipment/not in scope of delivery

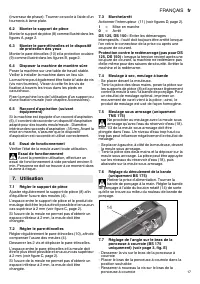

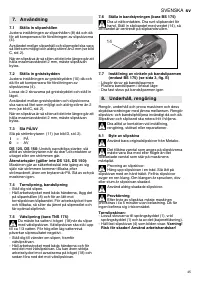

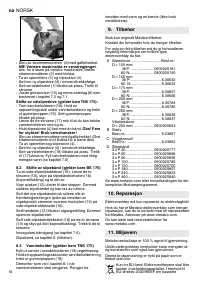

6.1 Power supply

Before plugging in, check that the rated mains

voltage and mains frequency, as stated on the

rating label, match with your power supply.

The grinder complies with protection class I and

must therefore only be connected to sockets

earthed according to specifications.

DSD 200, DSD 250 (three-phase version):

Ensure that the grinding wheels have the correct

direction of rotation (the correct direction of rotation

is indicated by an arrow on the side safety guards).

If a grinding wheel is rotating in the wrong direction:

Unplug the grinder. The plug comprises of two

phase conducting pins that are mounted on a

rotating socket (phase changing switch). Use a

Phillips screwdriver to rotate this socket.

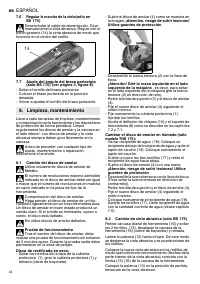

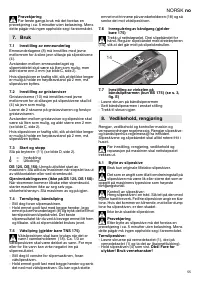

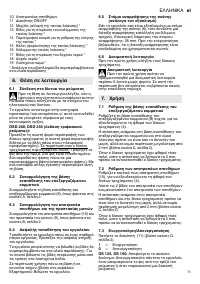

6.2 Installing workpiece support

Install workpiece support (8) as shown in illustrations

A, page 2.

6.3 Fitting spark deflector and eye

preservers

Install the spark deflector (10) and eye preservers (9)

as shown in illustrations B, page 2.

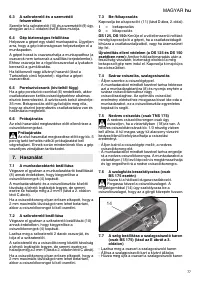

6.4 Installing machine safely

Place the machine on a stable workbench. Ensure

that the machine is securely seated.

The machine can also be bolted down (screws not

included in the scope of delivery). To do this, fasten

the securing screws through the holes in the rubber

feet.

If a stand or wall bracket is used (see Accessories

chapter): bolt down the machine.

6.5 Dust extraction connection (depending

on equipment)

If your machine is not equipped with a dust

extraction connection (6), fit an extraction device that

5. Overview

6. Initial Operation

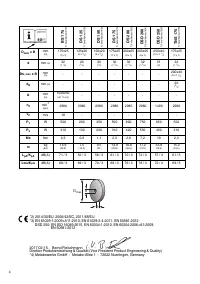

Характеристики

Остались вопросы?Не нашли свой ответ в руководстве или возникли другие проблемы? Задайте свой вопрос в форме ниже с подробным описанием вашей ситуации, чтобы другие люди и специалисты смогли дать на него ответ. Если вы знаете как решить проблему другого человека, пожалуйста, подскажите ему :)