Шуруповерты Stanley SCH201D2K - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

ENGLISH

(Original instructions)

10

♦

Tighten the first screw.

♦

If the clutch ratchets before the desired result is

achieved, increase the collar setting and continue

tightening the screw. Repeat until you reach the correct

setting. Use this setting for the remaining screws.

Note:

When using the Hammer drill for drilling holes, be

sure that the function collar is set so the figure of the drill

is aligned with the center line on the top of the tool. Failure

to do this will allow the clutch to slip while attempting to drill.

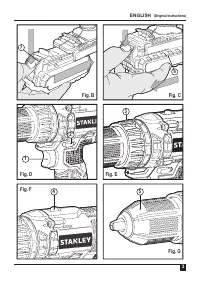

Dual range switch (Fig. F)

♦

The dual range feature of your drill allows you to shift

gears for greater versatility.

♦

To select low speed, high torque setting (position 1),

turn tool off and permit to stop. Slide gear shifter button

(4)

away from the chuck.

♦

To select the high speed, low torque setting (position 2),

turn tool off and permit to stop. Slide gear shifter button

back toward the chuck.

♦

Note:

Do not change gears when tool is running. If you

are having trouble changing gears, make sure that the

dual range gear button is either completely pushed

forward or completely pushed back.

Keyless chuck (Fig. G)

Warning!

Make certain the battery pack is

removed to prevent tool actuation before installing

or removing accessories.

To insert a drill bit or other accessory:

1.

Grasp the chuck

(5)

and rotate it in the counterclockwise

direction, as viewed from the chuck end.

2.

Insert the bit or other accessory fully into the chuck,

and tighten securely by rotating the chuck in the clockwise

direction as viewed from the chuck end.

@

Warning!

Do not attempt to tighten or

loosen drill bits (or any other accessory)

by gripping the front part of the chuck

and turning the tool on. Damage to the

chuck and personal injury may occur when

changing accessories.

Screw driving

♦

For driving fasteners, the forward/reverse button should

be pushed to the left.

♦

Use reverse (button pushed to the right) for removing

fasteners.

N

ote:

When moving from forward to reverse, or vice

versa, always release the trigger switch first.

Drilling

♦

Use sharp drill bits only.

♦

Support and secure work properly, as instructed in the

Safety Instructions.

♦

Use appropriate and required safety equipment, as

instructed in the SafetyInstructions.

♦

Secure and maintain work area, as instructed in the

SafetyInstructions.

♦

Run the drill very slowly, using light pressure, until the

hole is started enough to keep the drill bit from slipping

out of it.

♦

Apply pressure in a straight line with the bit. Use

enough pressure to keep the bit biting but not so much

as to stall the motor or deflect the bit.

♦

Hold the drill firmly with two hands

, one hand on the

handle, and the other gripping the bottom around the

battery area or the auxillary handle if provided.

♦

Do not click the trigger of a stalled drill off and on

in anattempt to start it. Damage to the drill can

result.

♦

Minimize stalling on break through by reducing ressure

and slowly drilling through the last part of the hole.

♦

Keep the motor running while pulling the bit out of a

drilled hole. This will help reduce jamming.

♦

Make sure switch turns drill on and off.

Drilling in Masonry (Fig. E)

1. Turn the collar (3) to the hammer drill symbol.

2. Select the high speed setting by sliding the selector

forward (towards the chuck). Important: Use carbide

tipped or masonry bits only.

3. Drill with just enough force on the hammer to keep

it from bouncing excessively or “rising” off the bit.

Too much force will cause slower drilling speeds,

overheating and lower drilling rate.

4. Drill straight, keeping the bit at a right angle to the

work. Do not exert side pressure on the bit when

drilling as this will cause clogging of the bit flutes and a

slower drilling. When drilling deep holes, if the hammer

speed starts to drop off, pull the bit partially out of the

hole with tool still running to help clear debris from the

hole.

Note:

A smooth, even flow of dust from the hole indicates

proper drilling rate speed.

Drilling in wood

Holes in wood can be made with the same twist drill bits

used for metal or with spade bits. These bits should be

sharp and should be pulled out frequently when drilling to

clear chips from the flutes.

Содержание

- 15 Русский язык

- 16 Год изготовления

- 19 Аккумулятор

- 20 «Технические; Комплект поставки; РЕКОМЕНДАЦИИ ПО ХРАНЕНИЮ

- 21 ИНСТРУКЦИИ ПО ЭКСПЛУАТАЦИИ

- 22 Курковый пусковой выключатель и

- 23 Заворачивание; The work light is for lighting the immediate work; Хранение насадок

- 24 безопасности; ДОПОЛНИТЕЛЬНЫЕ ПРИНАДЛЕЖНОСТИ; Аккумуляторы; ПРИМЕЧАНИЯ

- 25 Зарядное; Информация по техническому обслуживанию

- 27 Гарантийные условия