Шлифмашины Bosch PWS 8 125 CE - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

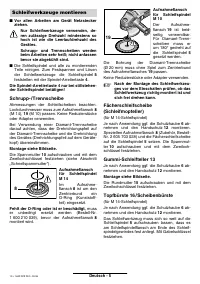

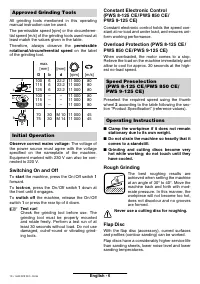

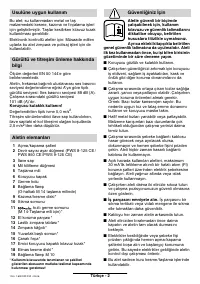

English - 5

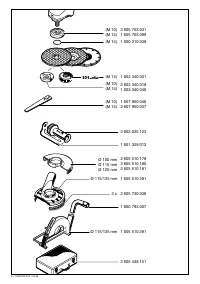

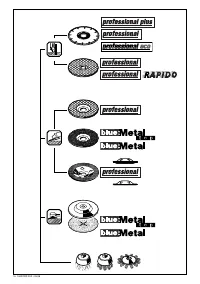

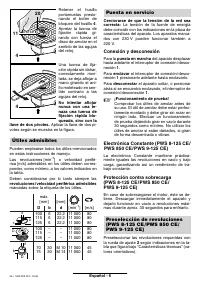

Grinding / Cutting Disc

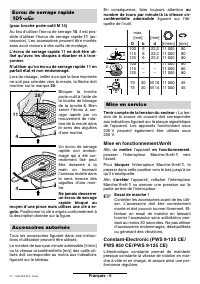

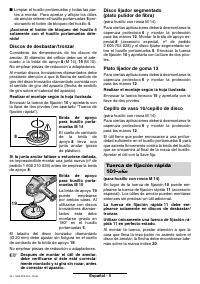

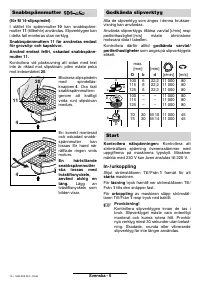

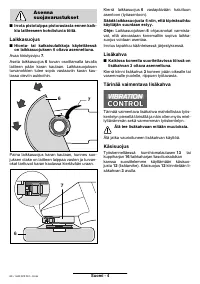

Observe the dimensions of the grinding discs.

The hole diameter must fit mounting

flange 8 (M 14), 19 (M 10). Do not use any re-

ducers or adapters.

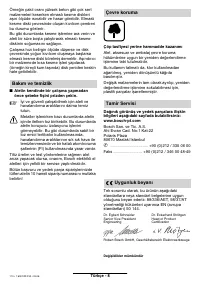

When using a diamond cutting disc, take care

that the direction-of-rotation arrow on the dia-

mond cutting disc and the direction of rotation of

the machine (direction-of-rotation arrow on the

machine head) agree.

For mounting, see the illustration page.

Screw on the clamping nut 10 and tighten with

the two-pin spanner (see Section “Quick-clamp-

ing Nut”).

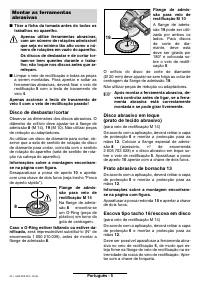

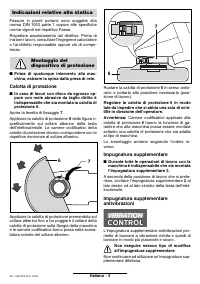

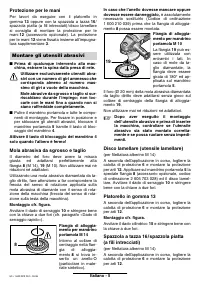

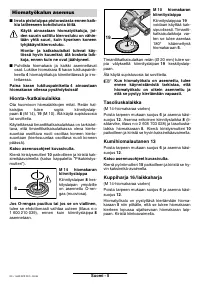

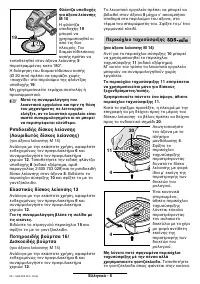

Mounting flange for

grinding spindle

M 14

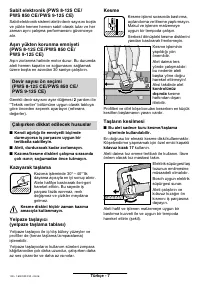

An O-ring (plastic

part) is inserted in the

mounting flange 8

around the spigot.

If the O-ring is missing or is damaged, it must

in all cases be replaced (Order No.

1 600 210 039) before the mounting flange 8 is

mounted.

Mounting flange for

grinding spindle

M 10

The mounting

flange 19 can be

used on both sides.

For diamond cutting

discs it must be posi-

tioned on the grind-

ing spindle 5 and

turned through 180°.

The bore of the diamond cutting disc (Ø 20 mm)

must fit the spigot of the mounting flange 19 with-

out any play.

Do not use any reducers or adapters.

☞

After mounting the grinding tool and be-

fore switching on, check that the grind-

ing tool is correctly mounted and that it

can turn freely.

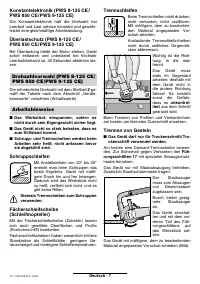

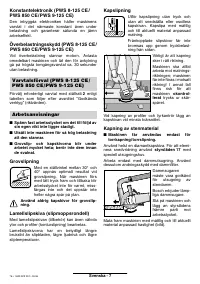

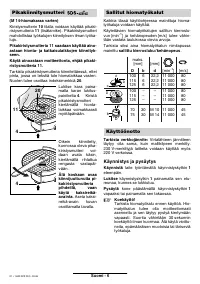

Flap Disc

(for M 14 grinder spindle)

Depending on the application, remove the protec-

tion guard 6 and mount the hand guard 12. Place

the special mounting flange 8 (accessory, Order

No. 2 605 703 028) and the flap disc on the

grinder spindle 5. Screw on the clamping nut 10

and tighten with the two-pin spanner.

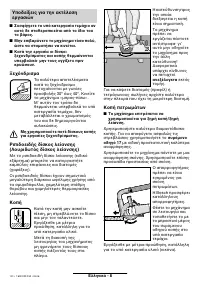

Rubber Sanding Pad 13

Depending on the application, remove the protec-

tion guard 6 and mount the hand guard 12.

For mounting, see the illustration page.

Screw on the round nut 15 and tighten with the

two-pin spanner.

Cup Brush 16 / Disc Brush

(for M 14 grinder spindle)

Depending on the application, remove the protec-

tion guard 6 and mount the hand guard 12.

The grinding tool must be able to be screwed

onto the grinding spindle 5 until it rests firmly

against the grinder spindle flange at the end of

the grinder spindle threads. Tighten with an

open-end spanner.

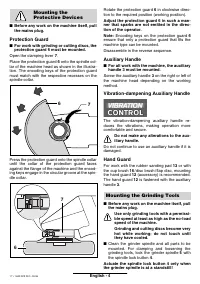

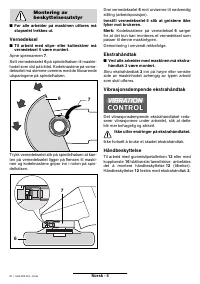

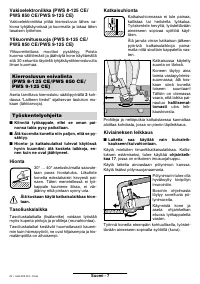

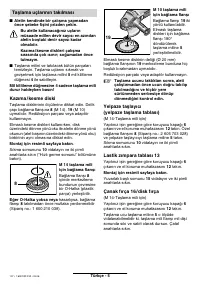

(for M 14 grinder spindle)

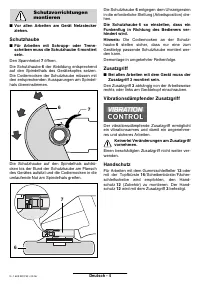

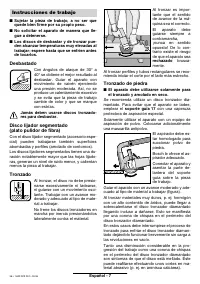

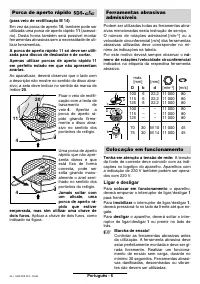

Instead of the clamping nut 10, the quick-clamp-

ing nut 11 (accessory) can be used. Grinding

tools can then be mounted without using tools.

The quick-clamping nut 11 may be used only

for grinding and cutting discs.

Use only a flawless, undamaged quick-clamp-

ing nut 11.

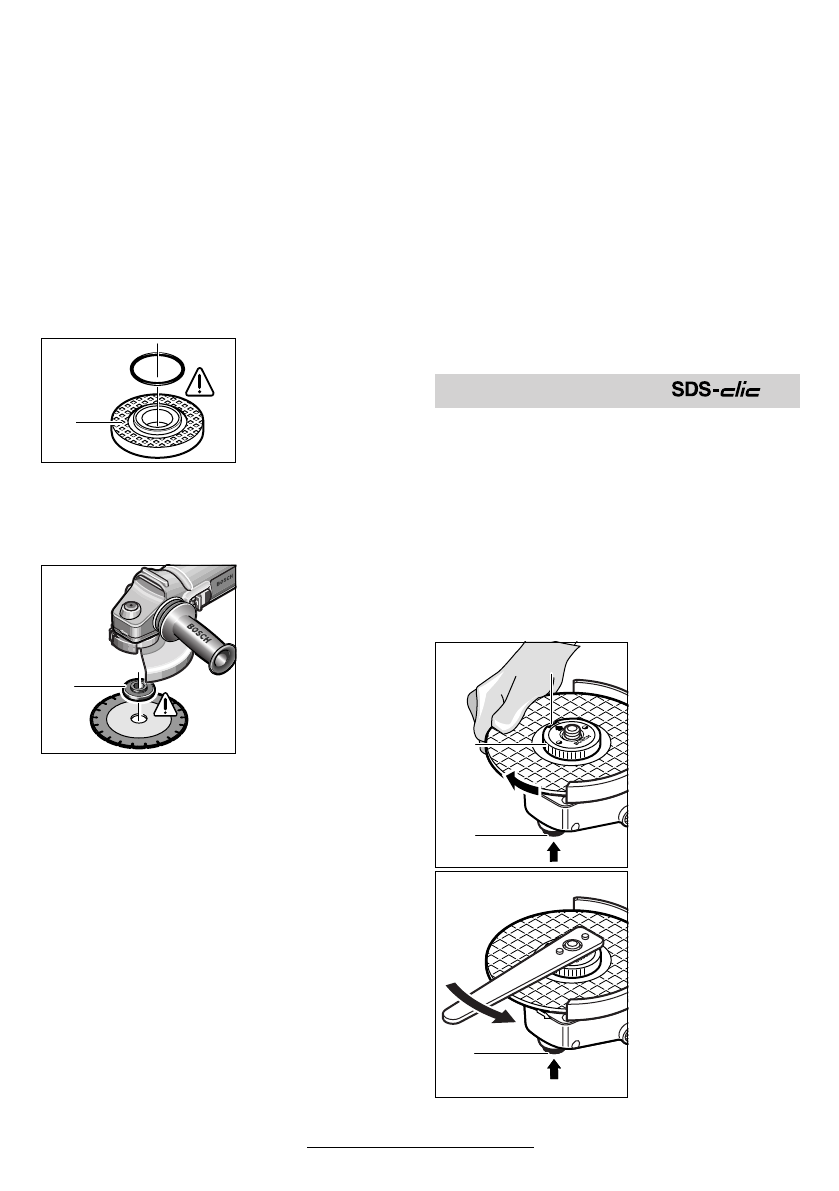

When screwing on, take care that the side with

printing does not point to the grinding disc. The

arrow must point to the index mark 20.

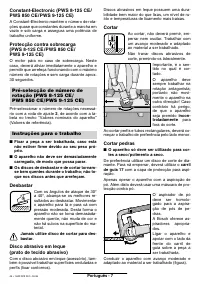

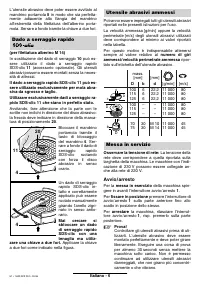

Lock the grinder

spindle with the spin-

dle lock button 4.

Tighten the quick-

clamping nut by

forcefully turning the

grinding disc in the

clockwise direction.

A properly tightened

undamaged, quick-

clamping nut can be

loosened by hand

turning the knurled

ring in the counter-

clockwise direction.

Never loosen a tight

quick-clamping nut

with pliers but use a

two-pin spanner. In-

sert the two-hole

spanner as shown in

the illustration.

8

19

Quick Clamping Nut

4

20

11

4

18 • 1 609 929 F32 • 03.06