Пилы дисковые Bosch GKS 600 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

16

| English

1 609 92A 1RW | (19.1.16)

Bosch Power Tools

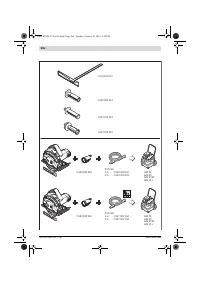

Assembly

Mounting/Replacing the Saw Blade

Before any work on the machine itself, pull the mains

plug.

When mounting the saw blade, wear protective gloves.

Danger of injury when touching the saw blade.

Only use saw blades that correspond with the charac-

teristic data given in the operating instructions.

Do not under any circumstances use grinding discs as

the cutting tool.

Selecting a Saw Blade

An overview of recommended saw blades can be found at the

end of this manual.

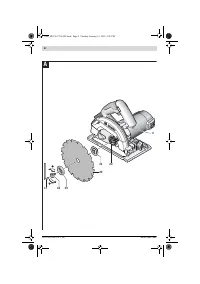

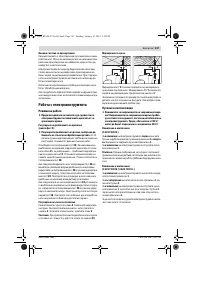

Removal of the Saw Blade (see figure A)

For changing the cutting tool, it is best to place the machine

on the face side of the motor housing.

– Press the spindle lock button

3

and keep it pressed.

The spindle lock button 3 may be actuated only when

the saw spindle is at a standstill.

Otherwise, the power

tool can be damaged.

– With the hex key

17

, unscrew the clamping bolt

18

turning

in rotation direction

.

– Tilt back the retracting blade guard

10

and hold firmly.

– Remove the clamping flange

19

and the saw blade

20

from

the saw spindle

22

.

Mounting the Saw Blade (see figure A)

For changing the cutting tool, it is best to place the machine

on the face side of the motor housing.

– Clean the saw blade

20

and all clamping parts to be assem-

bled.

– Tilt back the retracting blade guard

10

and hold firmly.

– Place the saw blade

20

on to the mounting flange

21

. The

cutting direction of the teeth (direction or arrow on saw

blade) and the direction-of-rotation arrow on the blade

guard

14

must correspond.

– Mount the clamping flange

19

and screw in the clamping

bolt

18

turning in rotation direction

. Observe correct

mounting position of mounting flange

21

and clamping

flange

19

.

– Press the spindle lock button

3

and keep it pressed.

– With the hex key

17

, tighten the clamping bolt

18

turning

in rotation direction

. The tightening torque is between

6 – 9 Nm, which corresponds to hand tight plus ¼ turn.

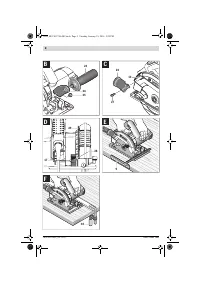

Mounting the Auxiliary Handle (see figure B)

Fasten the auxiliary-handle holder

24

with the locking screw

25

to the blade guard

14

.

Screw the auxiliary handle

23

on the auxiliary-handle holder

24

.

Dust/Chip Extraction

Before any work on the machine itself, pull the mains

plug.

Dust from materials such as lead-containing coatings,

some wood types, minerals and metal can be harmful to

one’s health. Touching or breathing-in the dust can cause

allergic reactions and/or lead to respiratory infections of

the user or bystanders.

Certain dust, such as oak or beech dust, is considered car-

cinogenic, especially in connection with wood-treatment

additives (chromate, wood preservative). Materials con-

taining asbestos may only be worked by specialists.

– As far as possible, use a dust extraction system suitable

for the material.

– Provide for good ventilation of the working place.

– It is recommended to wear a P2 filter-class respirator.

Observe the relevant regulations in your country for the

materials to be worked.

Prevent dust accumulation at the workplace.

Dust can

easily ignite.

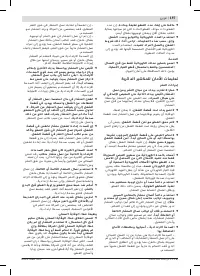

Mounting the Extraction Adapter (see figure C)

Attach the extraction adapter

26

onto the chip ejector

13

un-

til it latches. Secure the extraction adapter

26

additionally

with the screw

27

.

A vacuum hose with a diameter of 35 mm can be connected to

the extraction adapter

26

.

The extraction adapter may not be mounted when no

external dust extraction is connected.

Otherwise the ex-

traction channel can become clogged.

Do not connect a dust bag to the extraction adapter.

Otherwise the extraction system can become clogged.

To ensure optimum extraction, the extraction adapter

26

must be cleaned regularly.

External Dust Extraction

Connect the vacuum hose to a vacuum cleaner (accessory).

An overview for connecting to various vacuum cleaners can be

found at the end of this manual.

The machine can be plugged directly into the receptacle of a

Bosch all-purpose vacuum cleaner with remote starting con-

trol. The vacuum cleaner starts automatically when the ma-

chine is switched on.

The vacuum cleaner must be suitable for the material being

worked.

When vacuuming dry dust that is especially detrimental to

health or carcinogenic, use a special vacuum cleaner.

Operation

Operating Modes

Before any work on the machine itself, pull the mains

plug.

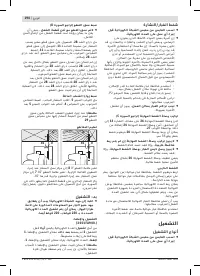

Adjusting the Cutting Depth (see figure D)

Adjust the cutting depth to the thickness of the work-

piece.

Less than a full tooth of the blade teeth should be

visible below the workpiece.

Loosen the clamping lever

28

. For a smaller cutting depth,

pull the saw away from the base plate

11

; for a larger cutting

depth, push the saw toward the base plate

11

. Adjust the de-

sired cutting depth at the cutting-depth scale. Tighten the

clamping lever

28

again.

OBJ_BUCH-2756-001.book Page 16 Tuesday, January 19, 2016 2:29 PM

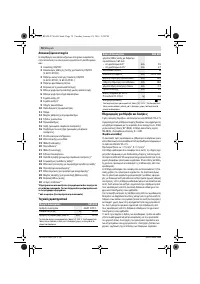

Содержание

- 114 Указания по безопасности

- 117 Описание продукта и услуг; Применение по назначению

- 118 Сборка; Установка/смена пильного диска; Отсос пыли и стружки

- 119 Работа с инструментом; Режимы работы

- 120 Техобслуживание и сервис; Техобслуживание и очистка

- 121 Утилизация; Українська; Вказівки з техніки безпеки; Загальні застереження для електроприладів

Характеристики

Остались вопросы?Не нашли свой ответ в руководстве или возникли другие проблемы? Задайте свой вопрос в форме ниже с подробным описанием вашей ситуации, чтобы другие люди и специалисты смогли дать на него ответ. Если вы знаете как решить проблему другого человека, пожалуйста, подскажите ему :)