Перфораторы VERTO SDS - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

9

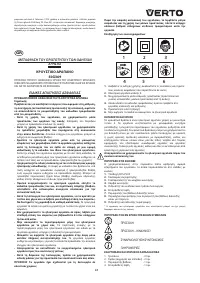

CONSTRUCTION AND USE

Rotary hammer is a hand-operated power tool with insulation class II.

The tool is driven by single-phase commutator motor with rotational

speed reduced with gear transmission. Rotary hammer can be used

for drilling holes in working modes: with impact, rotation only, digging

channels or surface processing of materials such as concrete, stone, brick

etc. Range of use covers repair and building works, woodworking and

any work from the scope of individual, amateur activities (tinkering).

Use the power tool according to the manufacturer’s instructions

only.

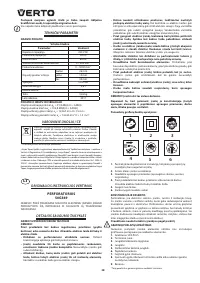

DESCRIPTION OF DRAWING PAGES

Below enumeration refers to the device elements depicted on the

drawing pages of this manual.

1.

SDS-PLUS chuck

2.

Fixing sleeve

3.

Switch lock button

4.

Switch

5.

Operation mode switch

6.

Additional handle

7.

Depth gauge rod

8.

Butterfly nut for fixing depth gauge rod

9.

Direction selector switch

* Differences may appear between the product and drawing

MEANING OF SYMBOLS

CAUTION

WARNING

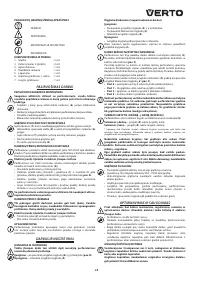

ASSEMBLY/SETTINGS

INFORMATION

EQUIPMENT AND ACCESSORIES

1. Drills

- 3 pcs

2. Chisels (point and flat)

- 2 pcs

3. Depth gauge rod

- 1 pce

4. Additional handle

- 1 pce

5. Transport case

- 1 pce

6. Drill chuck + key

- 1 pce

7. Chuck adapter

- 1 pce

PREPARATION FOR OPERATION

INSTALLATION OF ADDITIONAL HANDLE

Due to safety issues, always use additional handle (6) when

operating the rotary hammer drill. It can be fixed in any position.

•

Turn left the wheel lock that locks handle collar (

6

) to loosen it.

•

Slide the handle collar over cylindrical part of the rotary hammer drill

body.

•

Turn for the most comfortable position.

•

Turn the wheel lock tight to the right to clamp the handle.

INSTALLATION OF DEPTH GAUGE ROD

Depth gauge (

7

) serves to limit the depth of drill penetration of material.

•

Loosen the butterfly nut (

8

) on the additional handle collar (

6

).

•

Slide depth gauge rod (

7

) into the hole in the additional handle collar.

•

Set desired drilling depth.

•

Tighten the butterfly nut (

8

).

INSTALLATION AND REPLACEMENT OF WORKING TOOLS

Rotary hammer drill is designed to operate with working tools with

SDS-PLUS shanks. Prior to operation clean the rotary hammer drill and

working tools. Use lubricant and apply thin layer onto shank of the

working tool.

Disconnect the power tool from power supply.

Rotary hammer drill features clic-clic system (which does not require to

pull off the fixing sleeve (

2

) when installing a working tool).

•

Put the rotary hammer against stable surface.

•

Insert working tool shank into chuck (

1

) and slide it to mechanical

stop (it may be necessary to turn the working tool so it can reach

appropriate position) (

fig. A

).

•

Working tool is properly seated if it cannot be removed without

pulling off the fixing sleeve.

•

If the sleeve (

2

) does not return to its default position, remove the

working tool and repeat the whole operation.

High efficiency of the rotary hammer drill operation can be achieved

by using sharp and undamaged working tools.

DEINSTALLATION OF WORKING TOOL

Just after the operation is finished, the working tool may be hot.

Avoid direct contact and use appropriate protective gloves. Clean

the working tool after removal.

Disconnect the power tool from power supply.

•

Pull the fixing sleeve (

2

) to the back and hold.

•

Remove the working tool with your second hand by pulling it to the

front.

OVERLOAD CLUTCH

Rotary hammer drill features overload clutch with factory setting.

Spindle of the rotary hammer stops immediately after working tool jams,

what might overload the power tool.

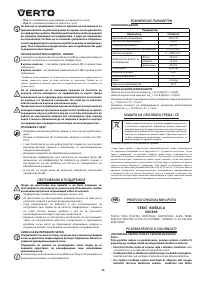

OPERATION / SETTINGS

SWITCHING ON / SWITCHING OFF

The mains voltage must match the voltage on the rating plate of the

rotary hammer drill.

Switching on

– press the switch button (

4

) and hold in this position (

fig. B

).

Switching off

– release pressure on the switch (

4

).

Locking the switch (continuous operation)

Switching on:

•

Press the switch button (

4

) and hold in this position.

•

Press the switch lock button (

3

).

•

Release pressure on the switch button (

4

).

Switching off:

•

Press and release the switch button (

4

).

Rotational speed of the spindle is controlled with pressure on the switch

button (

4

).

OPERATION MODE SWITCH

Rotary hammer drill features 3-function switch of the working mode (

5

).

Depending on its setting, a drilling only, impact drilling or chiselling is

possible (

fig. C

).

Impact drilling and chiselling requires to slightly press the rotary

hammer. Too great pressure would cause unnecessary, excessive load

of the motor. Check technical condition of the working tools regularly.

Sharpen or replace working tools when needed.

Press the switch lock button (

a

) prior to change of position of the

working mode switch (

5

) (

fig. C

).

• Pos0

= position for setting chisel in desired position (chiselling)

• Pos1

= regular drilling/screwing (symbol of a drill)

• Pos2

= impact drilling (symbol of a drill and a hammer)

• Pos3

= chiselling (symbol of a chisel and a hammer)

Do not try to change position of the working mode switch when the

motor of rotary hammer drill is operating. Such action may lead to

serious damage of the rotary hammer drill or even injury of the user.

Do not use three-jaw drill chuck, when the rotary hammer drill is set

to impact drilling. This chuck is designed for regular drilling only (in

wood or steel).

LEFT – RIGHT DIRECTION OF ROTATION

Choose direction of rotary hammer drill spindle rotation with the

selector switch (

9

).

Right rotation

– move the switch (

9

) to the extreme left position

Left rotation

– move the switch (

9

) to the extreme right position.

* The possibility is reserved that in certain cases position of the switch relating to

rotation direction may be different than specified. Please refer to graphic signs placed

on the switch or tool body.

Do not change direction of rotation when the spindle of the rotary

hammer drill is rotating. Ensure the position of the selector switch is

correct before starting the tool. Do not use left direction of rotation

when impact function is on.

Long lasting drilling at low rotational speed of the spindle may

cause motor overheating. Make periodic breaks during operation

or let the tool operate at maximum speed with no load for

approximately 3 minutes. Do not cover holes for motor ventilation

in the rotary hammer body.

IMPACT DRILLING

•

Choose appropriate mode of drilling, impact drilling in this case.

Характеристики

Остались вопросы?Не нашли свой ответ в руководстве или возникли другие проблемы? Задайте свой вопрос в форме ниже с подробным описанием вашей ситуации, чтобы другие люди и специалисты смогли дать на него ответ. Если вы знаете как решить проблему другого человека, пожалуйста, подскажите ему :)