Котел Baxi BPI Eco 1.550 / 1.650 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

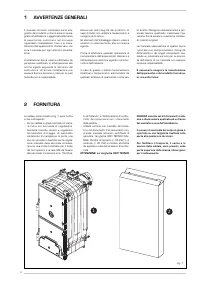

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

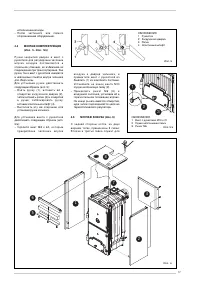

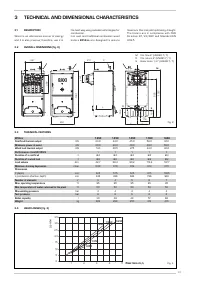

36

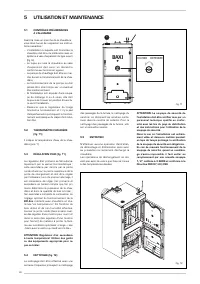

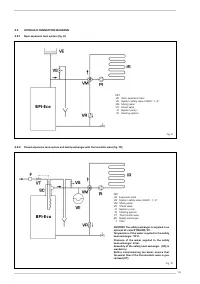

5.1

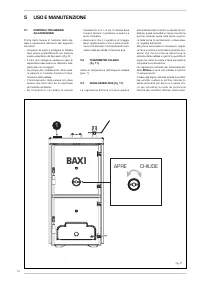

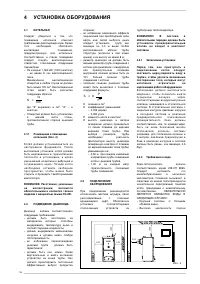

PRELIMINARY CHECKS

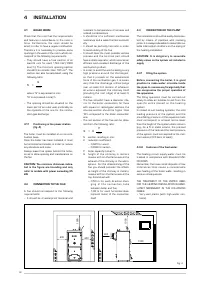

BEFORE COMMISSIONING

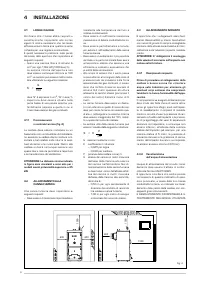

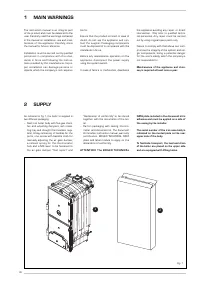

Before commissioning the boiler, comply

with the following instructions:

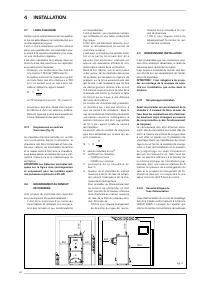

– The system connected to the boiler should

be with open expansion tank system (fig.

9).

– The pipe connecting t he boiler t o t he

expansion tank must have a suitable dia-

meter in compliance with the standards

in force.

– T h e h e a t i n g p u m p m u s t a l w a y s r u n

during the boiler operation.

– The operation of the pump must never

be interrupted by an environment ther-

mostat.

– If the system is equipped with 3 or 4-way

mixing valve, this must always be opened

towards the system.

– Ensure that the draught regulator runs

regularly and there are no obstructions

that block the automatic operation of the

air gate dumper.

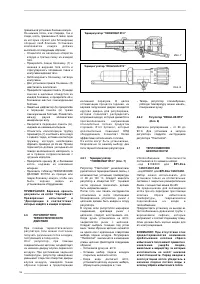

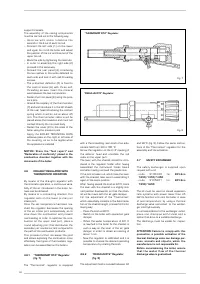

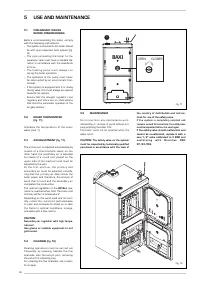

5.2

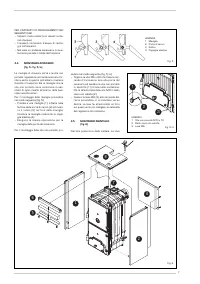

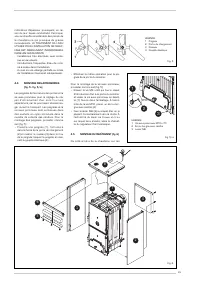

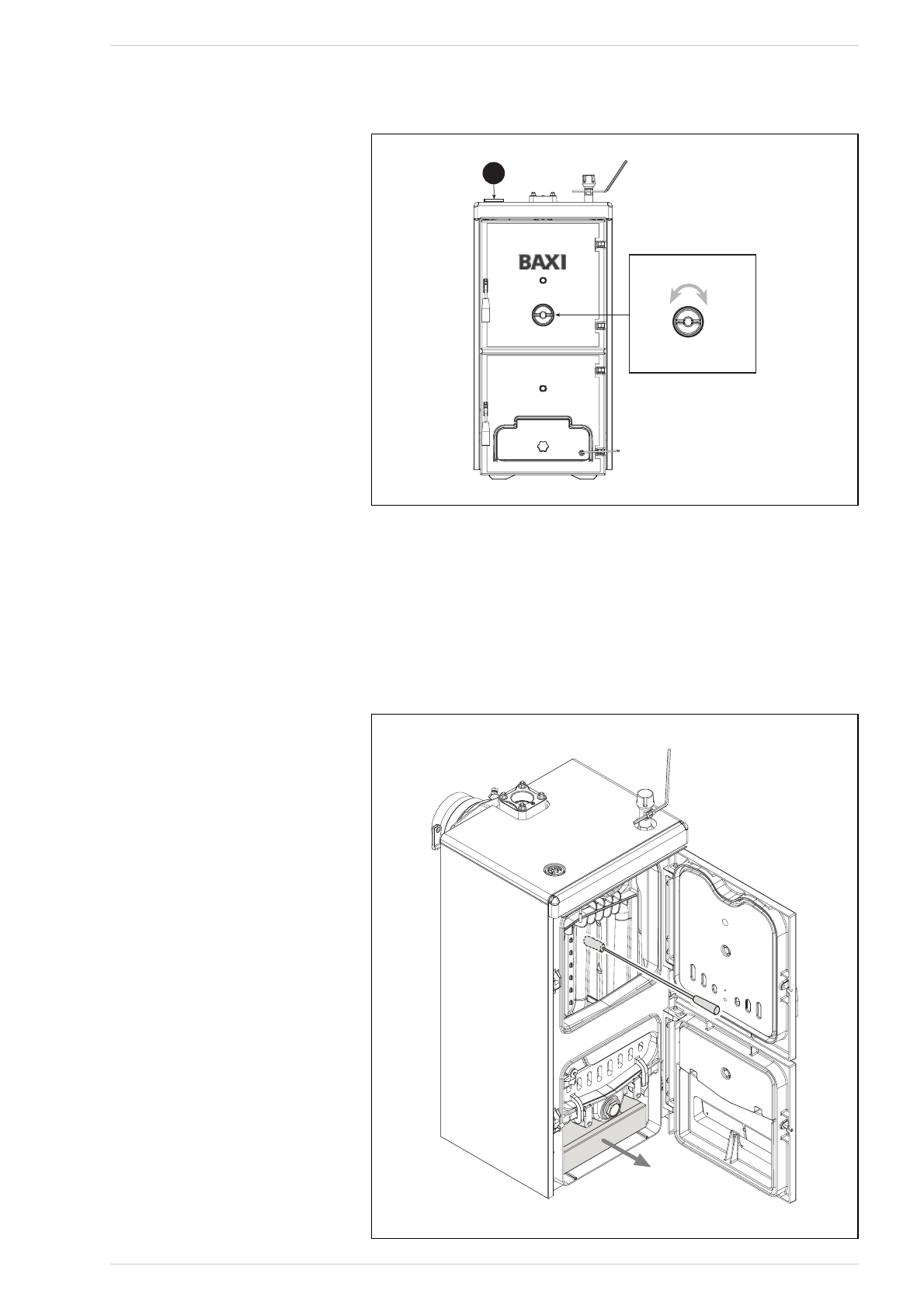

BOILER THERMOMETER

(fig. 11)

Indicat es t he t emper atur e of t he boiler

water (pos. 1).

5.3

AIR ADJUSTMENT (fig. 11)

The primary air is adjusted automatically by

m e a n s o f a t h e r m o s t a t i c v a l v e ; o n t h e

other hand, the secondary air is adjusted

by means of a round por t placed on the

upper side of the load por t and must be

adjusted by the user.

A t t h e f i r s t s t a r t - u p , t h e p r i m a r y a n d

secondary air must be adjusted, conside-

ring that the primar y air determines the

boiler power and, therefore, the amount of

wood that is burnt and the secondary air

completes the combustion.

The optimal regulation of the

BPI-Eco

ope-

ration is reached when both the boiler and

chimney will be "in temperature".

Depending on the wood used and its humi-

dity, rotate the round por t (anti-clockwise

to open and clockwise to close) so to take

t he f lame t o optimal conditions: orange-

pink-white with a blue centre.

CAUTION:

Secondary air regulator with high tempe-

ratures!

Use gloves or suitable equipment to not

get burned.

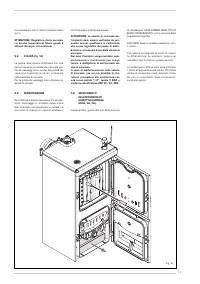

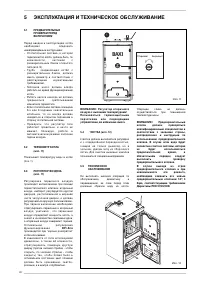

5.4

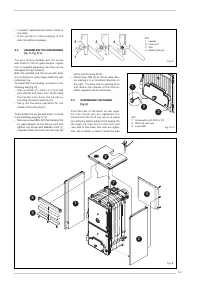

CLEANING (fig. 12)

Cleaning operations must be carried out

fr equentl y, by cleaning, besides t he f lue

channels, also the ash-pit por t, removing

the ash in the collecting tray.

For cleaning the flue channels, use a speci-

fic scraper.

5.5

MAINTENANCE

D o n o t p e r f o r m a n y m a i n t e n a n c e w o r k ,

dismantling or removal of parts without pro-

perly emptying the boiler first.

The boiler mus t no t be emptied when t he

water is hot.

CAUTION: The safety valve on the system

must be inspected by technically qualified

personnel in accordance with the laws of

the country of distribution and instruc-

tions for use of the safety valve.

I f t h e s y s t e m i s c o m p l e t e l y e m p t i e d a n d

remains unused for some time, the safety valve

must be inspected before it is used again.

If the safety valve should malfunction and

cannot be re-calibrated, replace it with a

new 1/2” valve calibrated to 3 BAR and

c o n f o r m i n g w i t h D i r e c t i v e P E D

97/23/CEE.

APRE

CHIUDE

1

5

USE AND MAINTENANCE

Fig. 11

Fig. 12

OPEN

CLOSES