Котел Baxi BPI Eco 1.550 / 1.650 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

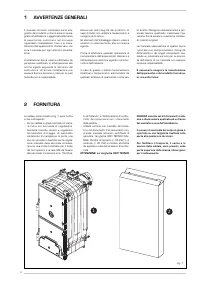

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

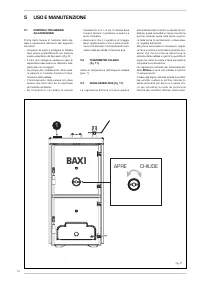

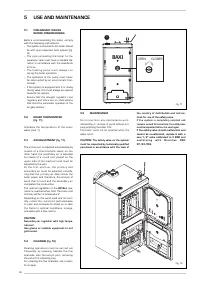

34

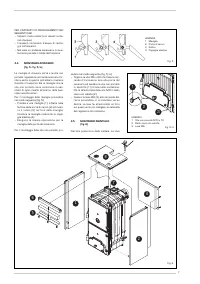

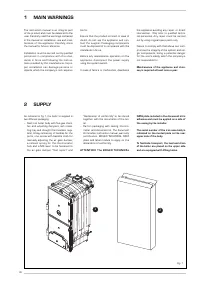

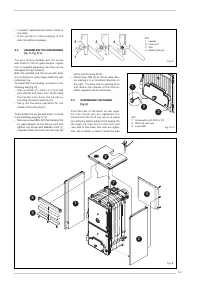

support brackets.

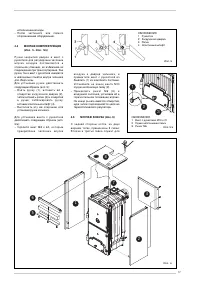

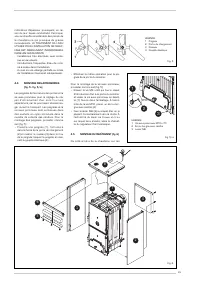

The assembly of the casing components

must be carried out in the following way:

– U n s c r e w w i t h s o m e r o t a t i o n s t h e

second or third nut of each tie rod.

– Connect the lef t side (1) on the lower

and upper tie rod of the boiler and adjust

the position of the nut and lock-nut of the

upper tie-rod.

– Block the side by tightening the locknuts.

– In order to assembly the right side (2)

proceed in the same way.

– Connect the rear panel (4) introducing

the two splines in the vents obtained on

each side and lock it with self-threading

screws.

– The protection deflector (5) is fixed to

t h e c o n t r o l p a n e l ( 6 ) w i t h t hr e e s e l f -

t hr eading scr ew s. Inser t t he miner al

wool between the two components.

– Fasten the front panel (6) using the pres-

sure pins.

– Unwind the capillary of the thermometer

(7) and and introduce it in the lef t sheath

of the rear head introducing the contact

spring which must be cut at about 45

mm. The thermomet er cable mus t be

placed above the insulation and must not

contact directly the iron cast body.

– Fasten the cover (8) to the sides of the

boiler using the pressure pins.

- A p p l y t h e B O I L E R T E C H N I C A L DATA

adhesive plate on the right or lef t side of

the covering, so as to be legible when

the appliance is installed.

N O T I C E : S t o r e t h e " Te s t r e p o r t " a n d

"Declaration of conformity" placed in the

combustion chamber together with the

documents of the boiler.

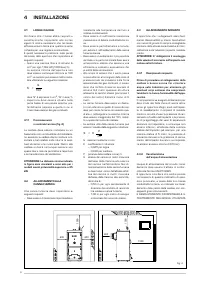

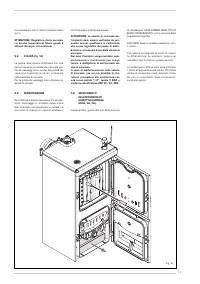

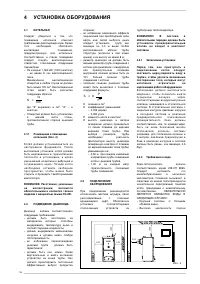

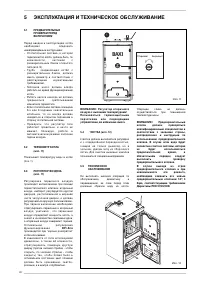

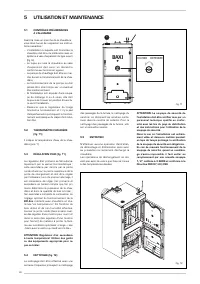

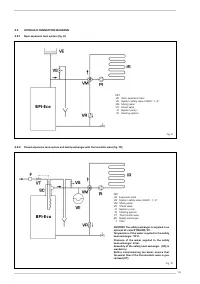

4.6

DRAUGHT REGULATOR WITH

THERMOSTATIC OPERATION

By means of t he draught r egulat or wit h

thermostatic operation, a continuous varia-

bility of the air introduced in the boiler fur-

nace can be obtained.

By means of a connecting chainle t, t his

r egulat or acts on t he lower pr imar y air

intake port.

Once the set temperature has been rea-

ched, the regulator decreases the opening

of the air intake por t automatically, so to

slow down t he combus tion and pr event

over-heating. In order to optimise the com-

bus tion on t he upper load por t, place a

round adjusting por t that distributes the

secondary air countercurrent compared to

the path of the combustion products.

This pr ocess fur ther incr eases the yield

and allows exploiting the combustion more

effectively. Two types of thermostatic regu-

lators can be assembled on the boilers.

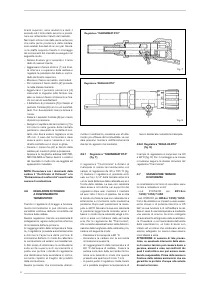

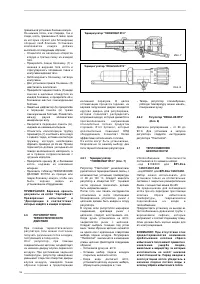

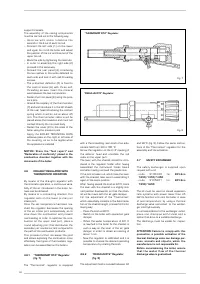

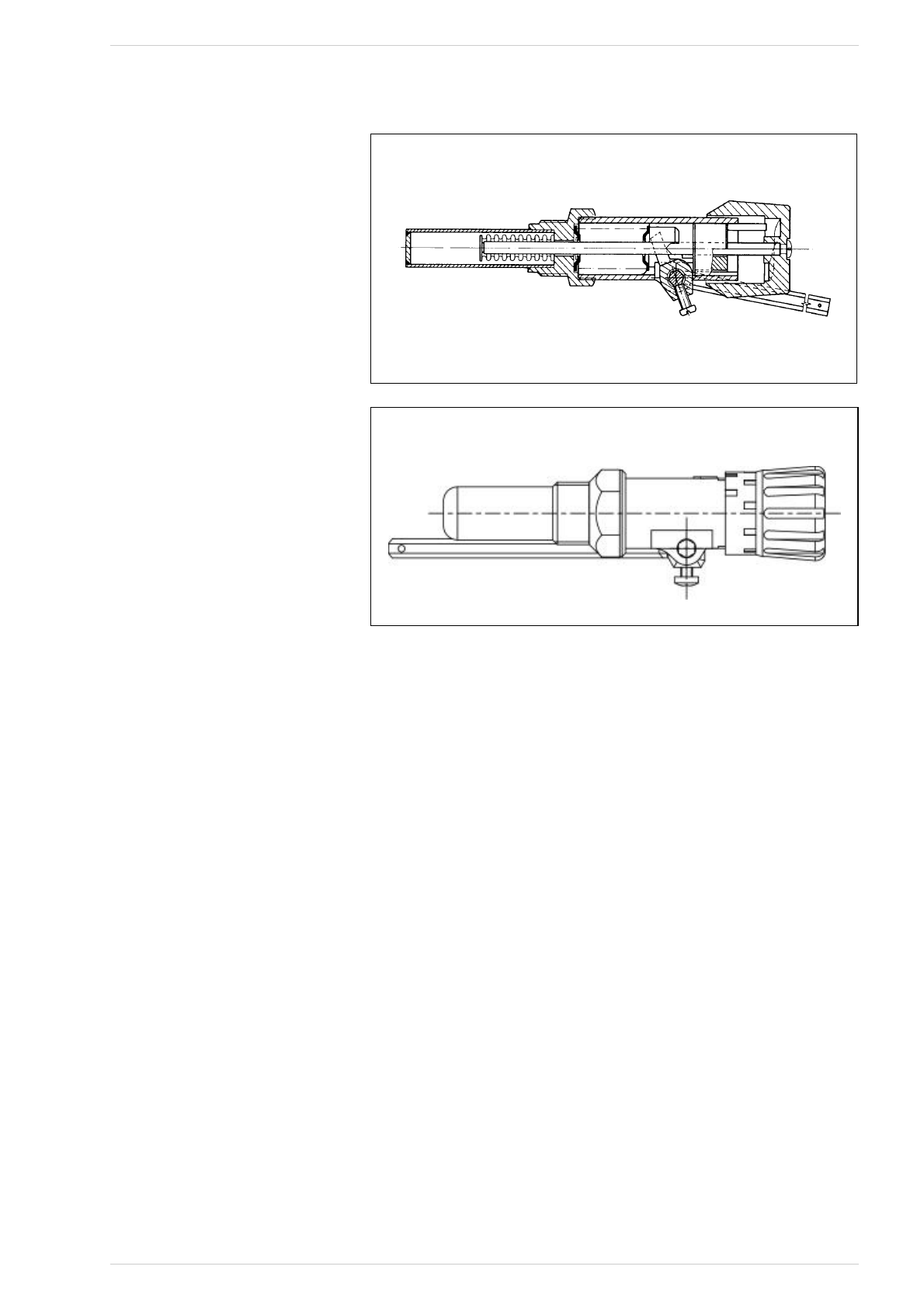

4.6.1

“THERMOMAT RT-C” Regulator

(fig. 7)

The “Thermomat” regulator is equipped

with a thermosetting resin knob of an adju-

stment field from 30 to 100 °C.

Screw the regulator on the 3/4” opening of

the anterior head and orientate the red

index on the upper part.

The lever with the chainlet should be intro-

duced in the regulator holder af ter having

assembled the instrument holder board

and af ter having removed the plastic lock.

If the joint is taken out, which fixes the lever

with the chainlet, take care in assembling it

again in the same position.

Af ter having placed the knob at 60°C, block

the lever with the chainlet in a slightly incli-

ned position downwards, so that the chain-

let will be in axis with the air gate damper.

For the adjustment of the “Thermomat”,

which essentially consists in the determina-

tion of the chainlet length, proceed in the fol-

lowing way:

– Place the knob at 60°C.

– Switch on the boiler with opened air gate

damper.

– When the water temperature of 60° C

is reached in the boiler, fix the chainlet in

such a way on the lever of the air gate

damper, in order to obtain an opening of

about 1 mm.

– Now the regulator is calibrated and it is

possible to choose the desired operating

temperature by rotating the knob.

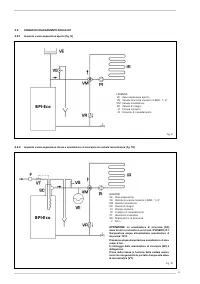

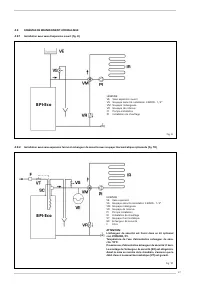

4.6.2

“REGULUS RT2” Regulator

(fig. 8)

The adjustment field is included between 30

and 90°C (fig. 8). Follow the same instruc-

tions of the “Thermomat” regulator for the

assembly and the activation.

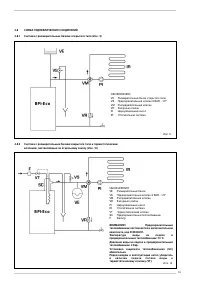

4.7

SAFETY EXCHANGER

T h e s a f e t y e x c h a n g e r i s s u p p l i e d u p o n

request with a kit:

- c o d e 810 5 2 0 0 f o r

B P I - E c o

1.250/1.350/1.450

-

c o d e 810 5 2 01 f o r

B P I - E c o

1.550/1.650

.

The kit must be used on closed expansion

t ank sys t ems with power lower than 35

kW. Its function is to cool the boiler in case

of over -t emperature, by using a thermal

discharge valve connected to the exchan-

ger inlet hydraulically.

In correspondence to the exchanger outlet,

p l a c e o n e d r a i n p i p e w i t h f u n n e l a n d a

siphon that drive to a suitable discharge.

The discharge must be visible for inspec-

tion.

ATTENTION: Failure to comply with this

precaution, a possible activation of the

thermal discharge valve can damage per-

s o n s , a n i m a l s a n d o b j e c t s , w h i c h t h e

manufacturer is not responsible for.

Before commissioning the boiler, ensure

t h a t t h e w a t e r f l o w o f t h e t h e r m a l

discharge valve is guaranteed.

Fig. 8

“REGULUS RT2” Regulator

Fig. 7

“THERMOMAT RT-C” Regulator