Фрезеры VERTO 52G710 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

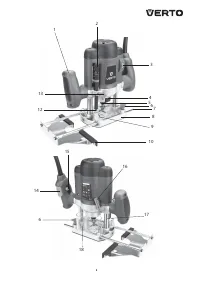

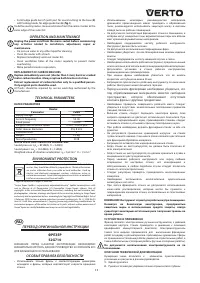

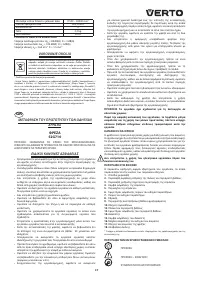

10

8.

Base

9.

Stepped cutting depth limiter

10.

Edge guide

12.

Depth gauge rod

13.

Depth gauge locking knob

14.

Switch

15.

Switch lock button

16.

Plunge guide locking lever

17.

Router plunge guide

18.

Dust outlet

* Differences may appear between the product and drawing

MEANING OF SYMBOLS

CAUTION

WARNING

ASSEMBLY/SETTINGS

INFORMATION

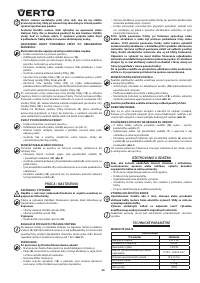

EQUIPMENT AND ACCESSORIES

1. Dust outlet

- 1 pce

2. Edge guide

- 1 pce

3. Edge guide bar

- 2 pcs

4. Bits

- 5 pcs

5. Collet sleeve

- 2 pcs

6. Profile guide

- 1 pce

7. Part for round cutting

- 1 pce

8. Flat spanner

- 1 pce

9. Bolts + nuts

- 1 set

10. Hexagonal key

- 1 pce

PREPARATION FOR OPERATION

DUST OUTLET INSTALLATION

Disconnect the power tool from power supply.

Dust outlet (

18

) allows to extract dust and shavings produced during

cutting with the help of vacuum suction devices or industrial vacuum

cleaners.

•

Loosen the plunge guide locking lever (

16

).

•

Place dust outlet (

18

) in the base (

8

) and fix with bolts (included) (

fig.

A

).

INSTALLATION AND REMOVAL OF WORKING TOOLS

Disconnect the power tool from power supply.

•

Hold the spindle nut (

5

) with flat spanner (included).

•

Press and hold spindle lock button (

4

).

•

Undo spindle nut (

5

) by turning it counter-clockwise (

fig. B

).

•

Remove bit, clean the spindle and install new bit so its shank goes at

least 20 mm deep into the collet sleeve.

•

Press the spindle lock button (

4

) and tighten the spindle nut (

5

).

•

Regularly check if the spindle nut (

5

) is tightened correctly.

Do not tighten the spindle nut before inserting a working tool.

Ensure appropriate collet sleeve is used each time the bit is replaced.

Spindle lock button can be used only for installation or removal of a

bit. It cannot be used as a brake-button when the spindle is rotating.

Otherwise the router may be damaged or the user may be injured.

SETTING PLUNGE DEPTH IN PROCESSED MATERIAL

Disconnect the power tool from power supply.

•

Place the router on even surface.

•

Unlock the plunge guide locking lever (

16

).

•

Overcome the spring resistance and bring down the router body, so

the bit touches surface the router is placed on.

•

Lock the tool in the position with the plunge guide locking lever (

16

).

•

Loosen the depth gauge locking knob (

13

).

•

Pull down the depth gauge rod (

12

) so it contacts one of surfaces of

the stepped cutting depth limiter (

9

).

•

Lift the depth gauge rod (

12

) up to the height of desired plunging of

cutter into the processed material. Tighten depth gauge locking knob

(

13

) to lock it in position.

When setting position of depth gauge rod (

12

) the scale located on

the router body is very helpful. You can achieve precise cutting depth

adjustment by turning knob for fine tuning of depth gauge rod (

2

). A

full turn of the knob shifts the depth gauge rod (

12

) vertically by 1 mm.

The router features stepped cutting depth limiter (

9

), that allows to

move (plunge) the cutter into material to one of seven equally spaced

positions (each pitch equals to approximately 3 mm) (

fig. C

).

ROUTER PLUNGING

•

Place the router on even surface.

•

Unlock the plunge guide locking lever (

16

) (

fig. D

).

•

Hold the handles with both hands and press the tool downwards,

overcoming the spring resistance.

•

Release the pressure, springs will automatically return the router body

to default (upper) position.

EDGE GUIDE INSTALLATION

Edge guide is used to cutting at even distance from edge of reference.

•

Use two bolts to join the edge guide bars (

7

) with the edge guide (

10

)

(

fig. E

).

•

Loosen locking knobs for edge guide bars (

6

) located in the router base.

•

Slide the edge guide bars (

7

) into the holes and set appropriate distance.

•

Tighten edge guide fixing knobs (

6

) to fix the edge guide (

10

).

OPERATION / SETTINGS

SWITCHING ON / SWITCHING OFF

The mains voltage must match the voltage on the router rating

plate.

The router is equipped with the switch lock button that protects against

accidental start up.

Switching on

•

Press the switch lock button (

15

).

•

Press and hold the switch button (

14

).

Switching off

•

Release pressure on the switch button (

14

).

ADJUSTMENT OF SPINDLE ROTATIONAL SPEED

Wheel for spindle speed adjustment (

3

) is located on the router body.

Select spindle speed depending on your needs (depending on the

cutter used, hardness of processed material, type of work etc.). Spindle

speed adjustment range is from 1 to 7 (

fig. F

).

ROUTING

Hold the router with both hands during operation!

•

Install appropriate router bit (see above instructions).

•

Put the base (

8

) on material that you plan to process (the router bit

must not touch the material at this time).

•

Set cutting depth.

•

Switch on the router with the switch (

14

) and wait until the spindle

achieves the preset idle speed.

•

Start working, move the router base along the processed material

surface in desired direction.

•

Move the router in steady, continuous movement, pressing the base

to the material surface all the time until you finish routing.

Too fast router advance during operation will result in low quality

of cutting and may cause damage of router bit or motor. Too

slow router advance may also result in low quality of cut due to

material overheating. Appropriate speed depends on size of the

router bit in use, type of processed material and cutting depth.

It is recommended to make some tries on waste material before

commencing the planned work. During edge processing, the

processed material should be at the left side from the router bit axis

(looking in the direction of the router advance).

When you use linear guide for linear processing or trimming, ensure

that additional accessories are well fixed.

INSTALLATION OF PROFILE GUIDE

Profile guide allows precise out-cutting inside and outside profiles.

•

Remove dust outlet (

18

) (remove fixing bolts).

•

Put profile guide in router base seating.

•

Install dust outlet (

18

) and tighten two parts with fixing bolts (

fig. G

).

Using profile guide limits allowable router bit size.

ROUTING DIRECTION

To avoid uneven edges and achieve best results of work, move the router

counter-clockwise for outer edges and clockwise for inner edges (

fig. H

).

USE OF PART FOR ROUND CUTTING

•

Remove edge guide (

10

) with edge guide bars (

7

) from the router

base.

•

Remove one of edge guide bar (

7

) and attach part for round cutting

to it.

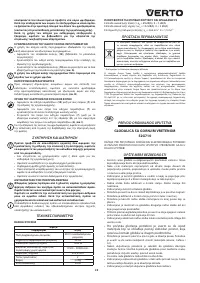

Характеристики

Остались вопросы?Не нашли свой ответ в руководстве или возникли другие проблемы? Задайте свой вопрос в форме ниже с подробным описанием вашей ситуации, чтобы другие люди и специалисты смогли дать на него ответ. Если вы знаете как решить проблему другого человека, пожалуйста, подскажите ему :)