Перфораторы Bosch GBH 5-40 DCE - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

English |

13

Bosch Power Tools

1 609 92A 0FN | (23.1.14)

applications, with different accessories or insertion tools or is

poorly maintained, the vibration emission may differ. This

may significantly increase the exposure level over the total

working period.

An estimation of the level of exposure to vibration should also

take into account the times when the tool is switched off or

when it is running but not actually doing the job. This may sig-

nificantly reduce the exposure level over the total working

period.

Identify additional safety measures to protect the operator

from the effects of vibration such as: maintain the tool and the

accessories, keep the hands warm, organisation of work pat-

terns.

Declaration of Conformity

We declare under our sole responsibility that the product de-

scribed under “Technical Data” is in conformity with the fol-

lowing standards or standardization documents: EN 60745

according to the provisions of the directives 2011/65/EU,

2004/108/EC, 2006/42/EC.

Technical file (2006/42/EC) at:

Robert Bosch GmbH, PT/ETM9,

D-70745 Leinfelden-Echterdingen

Robert Bosch GmbH, Power Tools Division

D-70745 Leinfelden-Echterdingen

Leinfelden, 24.01.2014

Assembly

Before any work on the machine itself, pull the mains

plug.

Auxiliary Handle

Operate your machine only with the auxiliary handle

10.

The auxiliary handle

10

can be set to any position for a secure

and low-fatigue working posture.

– Turn the bottom part of the auxiliary handle

10

in counter-

clockwise direction and swivel the auxiliary handle

10

to

the desired position. Then retighten the bottom part of the

auxiliary handle

10

by turning in clockwise direction.

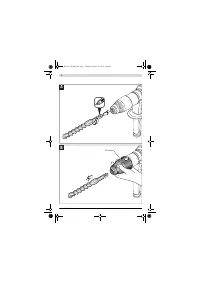

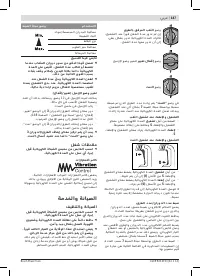

Changing the Tool

With the SDS-max tool holder, simpler and easier tool chang-

ing is possible without additional aids.

The dust protection cap

1

largely prevents the penetration of

dust into the tool holder during operation. When inserting the

tool, pay attention that the dust protection cap

1

is not dam-

aged.

A damaged dust protection cap should be changed im-

mediately. We recommend having this carried out by

an after-sales service.

Inserting (see figure A)

– Clean and lightly grease the shank end of the tool.

– Insert the tool in a twisting manner into the tool holder until

it latches itself.

– Check the latching by pulling the tool.

Removing (see figure B)

– Push back the locking sleeve

2

and remove the tool.

Dust/Chip Extraction

Dusts from materials such as lead-containing coatings, some

wood types, minerals and metal can be harmful to one’s

health. Touching or breathing-in the dusts can cause allergic

reactions and/or lead to respiratory infections of the user or

bystanders.

Certain dusts, such as oak or beech dust, are considered as

carcinogenic, especially in connection with wood-treatment

additives (chromate, wood preservative). Materials contain-

ing asbestos may only be worked by specialists.

– Provide for good ventilation of the working place.

– It is recommended to wear a P2 filter-class respirator.

Observe the relevant regulations in your country for the mate-

rials to be worked.

Operation

Starting Operation

Observe correct mains voltage! The voltage of the pow-

er source must agree with the voltage specified on the

nameplate of the machine. Power tools marked with

230 V can also be operated with 220 V.

To save energy, only switch the power tool on when using it.

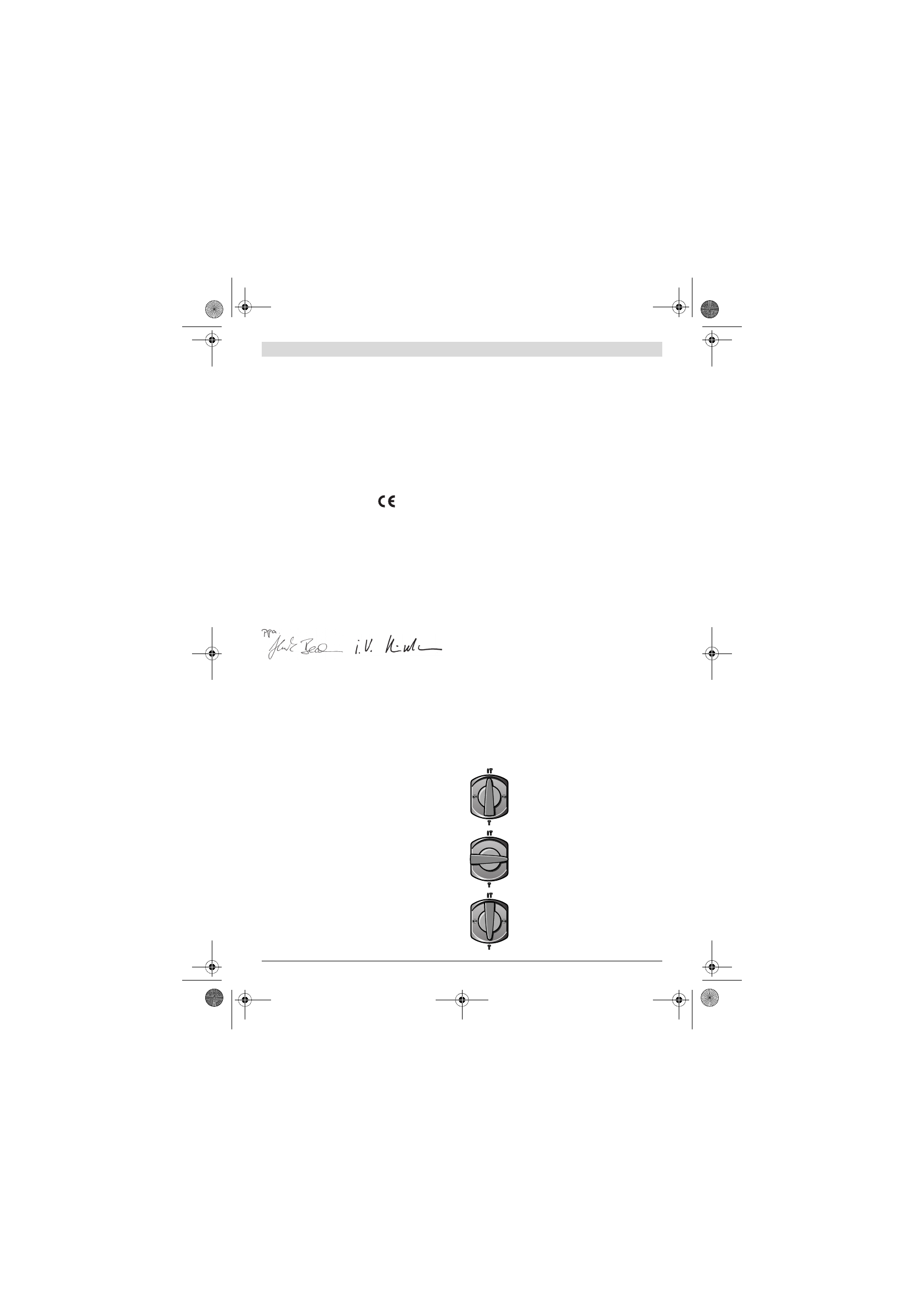

Setting the operating mode

The operating mode of the power tool is selected with the

mode selector switch

3

.

Note:

Change the operating mode only when the machine is

switched off! Otherwise, the machine can be damaged.

– Turn the mode selector switch

3

to the requested position.

Henk Becker

Executive Vice President

Engineering

Helmut Heinzelmann

Head of Product Certification

PT/ETM9

Position for

hammer drilling

When the drilling tool does not immediately

rotate upon switching on, allow the machine

to run slowly until the drilling tool rotates.

Vario-Lock

position for adjustment of the

chiselling position

Position for

chiselling

OBJ_BUCH-1742-003.book Page 13 Thursday, January 23, 2014 9:49 AM

Характеристики

Остались вопросы?Не нашли свой ответ в руководстве или возникли другие проблемы? Задайте свой вопрос в форме ниже с подробным описанием вашей ситуации, чтобы другие люди и специалисты смогли дать на него ответ. Если вы знаете как решить проблему другого человека, пожалуйста, подскажите ему :)