Мясорубки Zelmer 986.50 (53) (56) (57) (58) - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

74

Technical parameters

The technical parameters are indicated on the rating label.

Permissible duration of uninterrupted operation 15 minutes.

Break before the next use

30 minutes.

Noise level (L

WA

)

77 dB/A.

The appliance features double electrical insulation (Class II)

and does not require grounding

.

ZELMER mincers fulill the requirements of the existing

norms.

The appliance is in conformity with the requirements of the

directives:

Low voltage appliance (LVD) – 2006/95/EC.

–

Electromagnetic compatibility (EMC) – 2004/108/EC.

–

The appliance was marked by the CE sign on the rating

label.

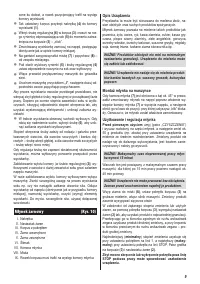

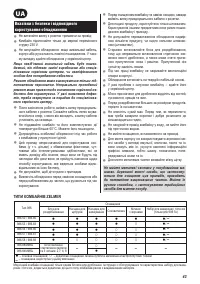

Description

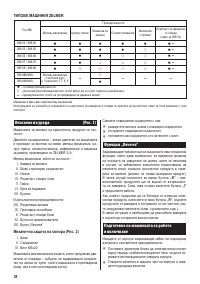

(Fig. 1)

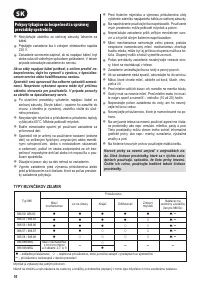

The food mincer consists of:

Mincer motor – each motor is adapted to install each

ZELMER mincing unit, citrus juicer, juicer, coffee grinder and

shredder.

The mincer unit consists of:

I. Mincer body

II. Scroll with clutch

III. Cutter

IV. Mincer screen with 4mm openings

V. Ring nut

VI. Tray

VII. Pusher

And additional accessories:

VIII. Base plate

IX. Sausage iller nozzle

X. Mincer screen with 8mm openings

XI. On/Off button.

XII. „Reverse” switch

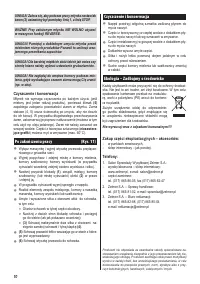

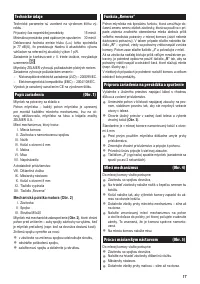

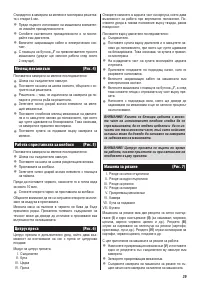

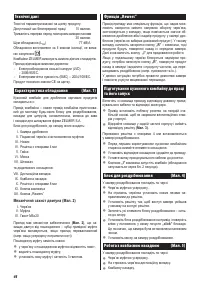

Mechanical safety device for the motor (Fig. 2)

I. Scroll

II. Clutch

III. Screw M5x20

The mincer is equipped with a mechanical safeguard, which

protects the motor against damage – the teeth in the clutch

break when the mincer is overloaded (e.g. when bones get

inside).

Replace the damaged clutch:

twist off the screw from the scroll with the damaged

●

clutch,

remove the damaged clutch,

●

attach the new clutch and tighten it with the screw.

●

„Reverse” function

The motor has a special function allowing to temporarily

change the direction of the scroll. It is used if mincing is

limited and/or if there is too much product in the mincer body

(the scroll does not take the product). Press the

„

R”

switch

for a short period of time, the product will be removed from

the inside of the mincer body. Press the

„I”

button once

again to continue operation.

If the scroll is still blocked by the excess of product, use the

„R”

switch once again, remove the product from the mincer

body and next remove product parts which make it dificult to

mince (e.g. sinews, etc.).

In some cases it is necessary to dismantle the mincer body

and remove the above-mentioned obstacles.

Preparing the appliance for operation and

switching on the appliance

Take out a suficient length of the supply cord and the

appropriate accessories from the compartment.

Place the motor near the socket, on a hard, stable

●

surface. Do not cover the ventilation openings of the

housing.

Open the compartment on the back of the housing and

●

take out an appropriate screen.

A screen with 4mm openings is installed in the mincer body

as a standard.

Wash all accessories thoroughly before the initial use.

●

Assemble the appropriate accessories and install them

●

on the motor.

Plug in the appliance.

●

Switch on the appliance using the

●

„I”

switch (the

appliance starts to operate after about 2 seconds).

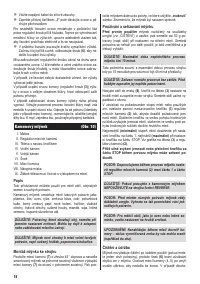

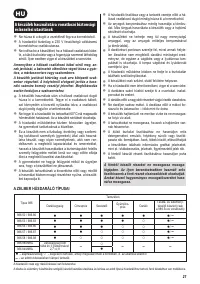

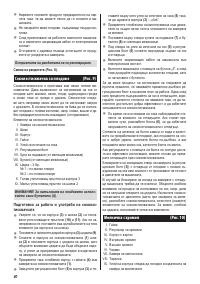

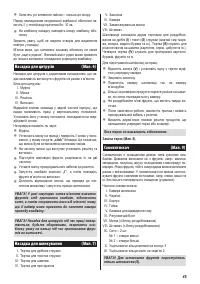

Mincing unit

(Fig. 4)

Fit the following elements in the mincer body:

The scroll with the clutch facing to the inside of the body.

●

The cutter to the bolt with the blades facing the screen.

●

The screen so that the protrusion of the body its the

●

groove in the circumference of the screen.

Tightly it all the elements of the mincer body.

●

Place the assembled mincer body on the motor and turn

●

left until you hear a click. It means that the body has

been properly installed.

Fit the tray to the mincer body.

●

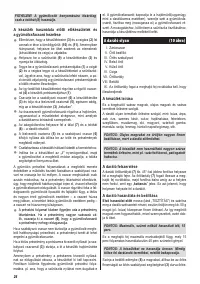

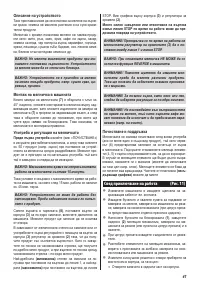

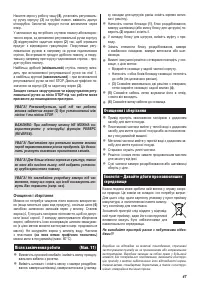

Operation with the sausage iller nozzle (Fig. 5)

Place the following elements in the mincer body:

The scroll with the clutch facing to the inside of the body.

●

The base plate to the bolt.

●

The sausage iller nozzle.

●

Tightly it all the elements with the ring nut.

●

Soak the casing for about 10 minutes before itting.